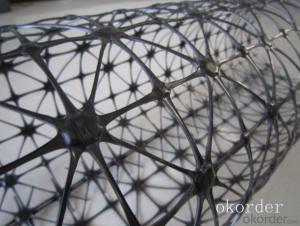

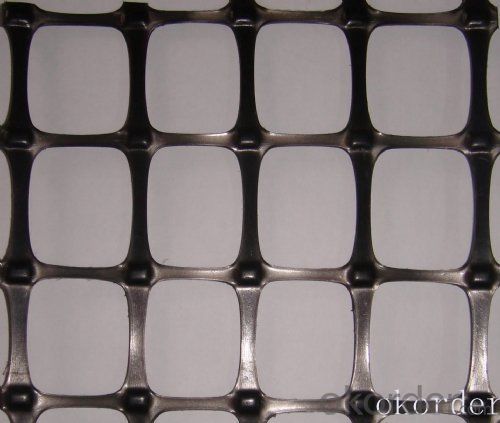

Egrid App Biaxial Geogrids - Good Toughness Polyethylene Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geogrids form a distinct category of geosynthetics designed for reinforcement.

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

Type:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the long-term performance monitoring requirements for geogrids?

- The long-term performance monitoring requirements for geogrids include regular inspections, assessment of durability and strength retention, measurement of creep and relaxation behavior, evaluation of long-term deformation and stability, and monitoring of the geogrid-soil interaction. Additionally, it is vital to monitor any potential degradation from environmental factors such as UV exposure, chemical exposure, and biological activity to ensure the geogrid's effectiveness over time.

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: What is the cost of geogrid installation?

- The cost of geogrid installation can vary depending on various factors such as the size of the project, the type and quality of geogrid being used, location, and labor costs. It is best to consult with a professional contractor or supplier to get an accurate estimate for your specific installation needs.

- Q: How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing reinforcement and reducing the potential for slope failures. They enhance the tensile strength of the soil, increase its stability, and prevent excessive movement or deformation. This is achieved by distributing the applied loads more evenly throughout the slope, reducing the pressure on the clayey soil, and increasing its resistance to shearing forces.

- Q: Are geogrids effective in stabilizing dredged material containment areas?

- Yes, geogrids are effective in stabilizing dredged material containment areas. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the containment of dredged material. They help distribute loads and reduce settlement, ensuring long-term stability and containment of the dredged material.

- Q: Are geogrids resistant to freeze-thaw cycles?

- Yes, geogrids are generally resistant to freeze-thaw cycles. Their material composition and design allow them to withstand the expansion and contraction caused by freezing and thawing temperatures without significant damage. This resistance makes geogrids suitable for various applications in cold climates where freeze-thaw cycles are common.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil structure, which helps distribute the load more evenly and prevent excessive settlement. They act as a stabilizing element by increasing the tensile strength of the soil, preventing its movement and settling.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used.

- Q: How do geogrids improve the performance of geocell-reinforced retaining walls?

- Geogrids enhance the performance of geocell-reinforced retaining walls by providing additional tensile strength and stability. They act as a reinforcement layer within the geocell structure, preventing soil movement and enhancing load distribution. This combination increases the overall strength of the retaining wall, allowing it to withstand higher loads and maintain structural integrity over time.

- Q: What are the criteria for Geogrid?Would like to know the price of Geogrid and geogrid manufacturers

- And then under the heating conditions of directional drawing. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

Send your message to us

Egrid App Biaxial Geogrids - Good Toughness Polyethylene Geogrid Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords