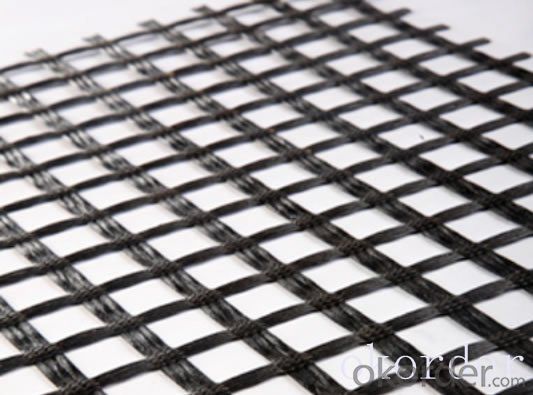

Reinforcement Geogrids - PP Plastic Polypropylene Biaxial Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

PP Plastic polypropylene geogrid biaxial

The properties of Biaxial Geogrids, made in Polypropylene (PP) with their square apertures, high tensile strength and optimised geometry of nodes and ribs make them equal to any other similar material.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in reinforcement of reinforced soil slopes?

- Yes, geogrids can be used in the reinforcement of reinforced soil slopes. Geogrids are often used to enhance the stability and strength of soil structures by providing tensile reinforcement.

- Q: Are geogrids suitable for use in reinforced slopes?

- Yes, geogrids are suitable for use in reinforced slopes. Geogrids are highly effective in stabilizing and reinforcing slopes by providing increased tensile strength and distributing loads more evenly. They enhance the stability of the soil, prevent erosion, and can be used in various types of reinforced slope applications, making them a suitable choice for such projects.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q: Can geogrids be used in stormwater detention systems?

- Yes, geogrids can be used in stormwater detention systems. Geogrids are commonly used as a reinforcement material in these systems to enhance the stability and strength of the soil. They help to prevent soil erosion, improve drainage, and increase the overall efficiency of stormwater detention systems.

- Q: Are geogrids suitable for railway track stabilization?

- Yes, geogrids are suitable for railway track stabilization. Geogrids are commonly used in railway construction and maintenance projects to enhance the stability and load-bearing capacity of the tracks. They provide reinforcement and prevent lateral movement of the ballast, helping to reduce track settlement and increase track longevity. Geogrids also improve the overall performance and safety of the railway infrastructure by minimizing track deformations and improving drainage.

- Q: Can geogrids be used in reinforcement of pavement overlays?

- Yes, geogrids can be used in the reinforcement of pavement overlays. Geogrids are commonly used to enhance the strength and stability of pavement overlays by distributing loads, reducing cracking, and increasing the lifespan of the pavement.

- Q: Are geogrids suitable for use in reinforced embankments?

- Yes, geogrids are suitable for use in reinforced embankments. Geogrids are commonly used in civil engineering projects to provide stability and prevent soil erosion. They are particularly effective in reinforcing embankments by distributing loads and reducing deformation, thus improving the overall performance and longevity of the structure.

- Q: What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include ASTM D6637, which provides testing methods for determining the tensile properties of geogrids, and ASTM D5262, which specifies the requirements for geogrids used in soil stabilization applications. Additionally, ISO 10318 and EN 15381 are international standards that outline the design, testing, and performance characteristics of geogrids for various applications. These standards ensure that geogrids meet specific criteria for strength, durability, and performance, allowing engineers and designers to choose the appropriate geogrid for their specific project requirements.

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing

- Geogrid in flat lower bearing layer according to design requirements of the laying of the width, lower filler unarmed bad geogrid debris, geogrid, the high strength in the direction perpendicular to the axial direction of embankment layout, geogrid transverse laying, laying taut, stretched, and avoid wrinkle twist or potholes, geogrid along the longitudinal splicing by overlapping method, lap width not less than 20cm.

- Q: What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they provide reinforcement to the soil, increasing its bearing capacity and allowing it to support heavy loads. This helps to prevent settlement and stability issues that can arise from excessive loading. Secondly, geogrids distribute the load more evenly across the ground, reducing the stress concentration that can occur at specific points. This helps to minimize the risk of localized failures and ensures a more uniform transfer of loads. Additionally, geogrids improve the overall performance of the ground by increasing its stiffness and reducing deformations. This can be particularly beneficial in areas with weak or poorly compacted soils, as it enhances the stability and load-bearing capacity of the ground. Furthermore, geogrids are cost-effective compared to traditional methods of ground improvement, such as deep foundation systems. They require less material and labor, resulting in reduced construction costs and shorter project timelines. Overall, the advantages of using geogrids in ground improvement for load transfer platforms include increased bearing capacity, improved load distribution, enhanced ground performance, and cost savings.

Send your message to us

Reinforcement Geogrids - PP Plastic Polypropylene Biaxial Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords