Geotextil Szeged Slope Geocell (Plastic Slope Geocell)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Slope Geocell:

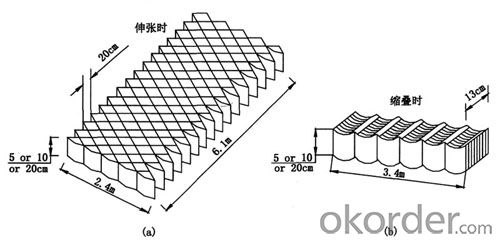

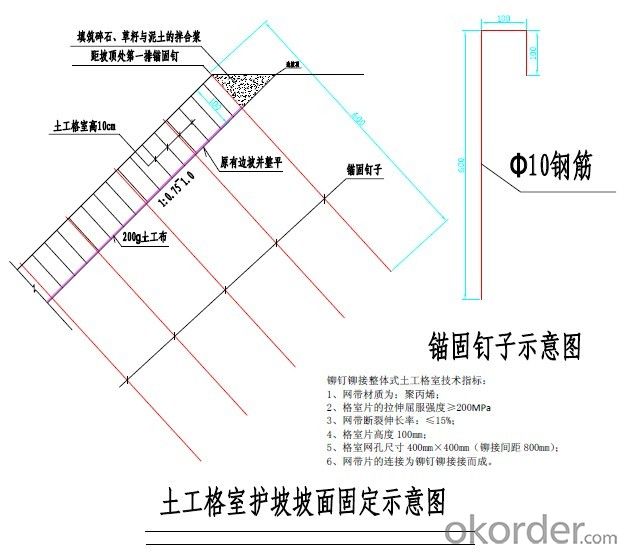

The soil work space room is to be take by the HDPE breadth of the high strength, was become by strong dint welding of have the net space room structure, it flex from such as, the conveyance can fold, usage the hour opens and hurtles to fill the ground, or concrete to anticipate, constituting to have the strong side to limit and greatly just the structure body of the degree. Can use to be the mat layer, handle the loading ability that the weak foundation enlarges the foundation, also can build to constitute the ÆÂ to face the protection structure on the bedcover, can also use to construct to pay file structure etc.

Main Features of Plastic Slope Geocell:

Notes:When you are ready to inquire hdpe geocell,pls indicate your specifications as follows:

1.Geocell Height(50mm to 200mm).

2.Welding Distance(330mm to 1000mm).

3.Seam Peel Strength(1000N/10cm,1200N/10cm,1400N/10cm).

4.HDPE Sheet Thickness(1.1mm,1.2mm,1.5mm,1.75mm).

Specifications of Plastic Slope Geocell:

Technical Data

Art No. | Width(cm) | Length (cm) | Height (mm) |

Welding Interval (mm) | Thickness (mm) | Unit Weight (g/m2) | Peeling Strength at Welding Point ( N/ mm) | Peeling Strength at Connecting ( N/ mm) | Slice Yield Strength ( N/ mpa) |

PLC0301 | 600 | 400 | 50 | 400 | 1 | 550 | 10 | 10 | 18 |

PLC0302 | 600 | 400 | 75 | 400 | 1 | 850 | 10 | 10 | 18 |

PLC0303 | 600 | 400 | 100 | 400 | 1 | 1100 | 10 | 10 | 18 |

PLC0304 | 600 | 400 | 150 | 400 | 1 | 1600 | 10 | 10 | 18 |

PLC0305 | 600 | 400 | 200 | 400 | 1 | 2200 | 10 | 10 | 18 |

Remarks: A breadth of product can press customer to request to create at will, other special specification according to agreement or contract performance. | |||||||||

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Remarks: 1. This is a basic technical specification. 2. All of the technical indexes can be reached according to the customers' demand, and the other special standards will be carried out by agreement or contact.

| ||||||

Applications of Plastic Slope Geocell:

How to make Geocell

Walk into our factory

IMages of Plastic Slope Geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: The properties of woven geotextiles

- Product features: 1, with a reinforcement function: to stabilize the project in the course of prolonged use of the transfer occurred, and can be the role of the soil in the local stress transmission or assigned to a larger area. 2, with the role of separation: woven geotextile with different geotechnical structure to form a stable interface, in accordance with the requirements to play their own characteristics and the overall role. 3, the role of drainage filter: allow moisture to block the loss of sand particles, in the drainage of geotextiles on the poor water in the soil can play the water along the geotextile quickly discharged the purpose. 4, the geotextile and geomembrane used in two different pressures between the material can play a role in tension diaphragm. 5, with a block function: the geotextile placed in the flow of liquid with suspended particles in the channel to organize fine mud particles, and allow the liquid through the function. 6, play the role of cushion mat: the geotextile placed on the slope can prevent the soil particles due to the erosion of rain and the loss or planting turf.

- Q: How do geotextiles help with erosion control in river channels?

- Geotextiles aid in erosion control in river channels by acting as a protective barrier against soil erosion. They are placed along the riverbanks or riverbeds to prevent the loss of soil particles due to water flow. Geotextiles stabilize the soil, increase its resistance to erosion, and promote vegetation growth. Additionally, they allow water to pass through while retaining sediment, thus reducing sedimentation in the river channel.

- Q: Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q: Are geotextiles suitable for use in geocell mattress systems?

- Yes, geotextiles are suitable for use in geocell mattress systems. Geotextiles provide stability, erosion control, and reinforcement to the mattress system, making it an effective solution for soil stabilization and erosion prevention. They enhance the overall performance and durability of the geocell mattress system.

- Q: Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q: How are geotextiles used in erosion control?

- Geotextiles are used in erosion control by providing a protective barrier against soil erosion. They are placed on the ground surface or buried within the soil to prevent or minimize the loss of soil particles due to water flow or wind. Geotextiles help stabilize the soil by improving its strength and reducing the movement of sediments, thus preventing erosion from occurring.

- Q: Can geotextiles be used in green wall construction?

- Yes, geotextiles can be used in green wall construction. Geotextiles are commonly used as a stabilizing layer to retain soil and provide drainage in green wall systems. They help prevent erosion, promote healthy plant growth, and enhance the structural integrity of the wall.

- Q: Geotextile and blind tube is how the drainage ah?

- Geotextile from the role of filtration, over the water, but soil, geotextile wrapped around the blind ditch like, I am specializing in the production of geotextiles, geomembrane and other materials, wish smooth.

- Q: Can geotextiles be used in seawall construction?

- Yes, geotextiles can be used in seawall construction. Geotextiles are commonly used in seawall construction as they provide reinforcement, erosion control, and filtration. They help to stabilize the soil, prevent erosion, and allow for proper drainage, making them a valuable component in the construction of seawalls.

- Q: How do geotextiles improve the performance of geopipes?

- Geotextiles improve the performance of geopipes by providing additional reinforcement and filtration capabilities. They act as a barrier to prevent soil particles from entering the pipe, reducing the risk of clogging and maintaining the pipe's hydraulic conductivity. Additionally, geotextiles increase the overall strength of the system, distributing the load more evenly and enhancing the pipe's structural integrity.

Send your message to us

Geotextil Szeged Slope Geocell (Plastic Slope Geocell)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords