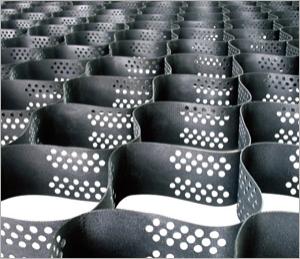

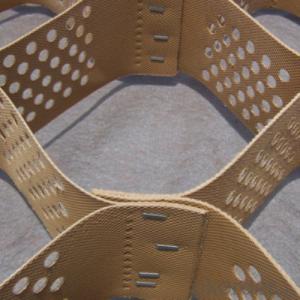

HDPE Plastic Slope Erosion Geocells / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Plastic Geocell

Geocell is honeycomb shaped structures using material of HDPE or PP, welded by high frequency ultrasonic.

Main Features of HDPE Plastic Geocell

Geocell Cellular Confinement Systems / Geocell / Geocell systems / HDPE Smooth/Textured Plastic Geocell

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specifications of HDPE Plastic Geocell

1.Height:50mm-200mm

2.Welding distance:330mm-1000mm

3.Thickness of sheet: 1.0mm-1.5mm

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Applications of HDPE Plastic Geocell

To stable the roadbed of highway/railway.

To bear the load of dyke, retaining wall.

To improve the watercourse of shallow river.

To support the pipeline and sewer.

To be used as independent wall, wharf and breakwater, etc..

To be used for the regulation of the desert, beaches, river bed and river bank.

IMages of HDPE Plastic Geocell

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q: Can geocells be used for groundwater protection?

- Yes, geocells can be used for groundwater protection. Geocells are three-dimensional cellular structures made of geosynthetic materials that can be filled with various materials like soil, gravel, or sand. These cells can be installed to create a protective barrier around groundwater sources, preventing contamination from surface pollutants or controlling the flow of groundwater. Additionally, geocells can also help with erosion control, stabilize slopes, and improve the overall quality and sustainability of groundwater resources.

- Q: What is the load-bearing capacity of geocells?

- The load-bearing capacity of geocells depends on various factors such as the type and thickness of the geocell material, the soil conditions, and the intended application. However, geocells are typically designed to withstand significant loads, ranging from light pedestrian traffic to heavy vehicular loads or even the weight of structures. It is important to consult with an engineer or manufacturer to determine the specific load-bearing capacity of geocells for a particular project.

- Q: Do geocells require any special permits for installation?

- Yes, geocells typically do not require any special permits for installation. They are considered a temporary or semi-permanent solution and are often classified as erosion control or soil stabilization products rather than permanent structures. However, it is always advised to check with local authorities or building codes to ensure compliance with any specific regulations in the area of installation.

- Q: Can geocells be used for embankment construction?

- Yes, geocells can be used for embankment construction. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene materials. They can be filled with various materials such as soil, gravel, or concrete to create a stable and reinforced embankment. The cells provide confinement and support to the fill material, preventing lateral spreading and enhancing load-bearing capacity. This makes geocells a cost-effective and environmentally-friendly solution for embankment construction in various civil engineering projects.

- Q: What is the effect of aging on geocell performance?

- The effect of aging on geocell performance can lead to a decrease in its mechanical properties over time. As the geocell ages, it may experience degradation due to environmental factors such as UV exposure, temperature fluctuations, and moisture absorption. This can result in a loss of stiffness, reduced load-bearing capacity, and decreased overall effectiveness in soil stabilization and erosion control applications. Therefore, regular inspection and maintenance are necessary to ensure optimal geocell performance and longevity.

- Q: Can geocells be used on slopes with high inclinations?

- Yes, geocells can be used on slopes with high inclinations. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene. They provide reinforcement and stabilization to slopes by confining and containing soil or aggregate materials. Geocells are effective in preventing soil erosion, reducing surface water runoff, and enhancing slope stability even on steep slopes with high inclinations.

- Q: Can geocells be used for railway trackbed stabilization?

- Yes, geocells can be used for railway trackbed stabilization. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene materials. They can be filled with various infill materials, such as soil or aggregate, to create a stable and reinforced platform for railway tracks. Geocells provide confinement to the infill material, preventing lateral spreading and enhancing load distribution. This helps to reduce settlement, increase track stability, and improve overall performance of the railway trackbed.

- Q: Can geocells be used for railway ballast reinforcement?

- Yes, geocells can be used for railway ballast reinforcement. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) material. They are designed to confine and reinforce granular materials, such as ballast, by providing lateral restraint and preventing lateral movement. This makes them suitable for enhancing the stability and load-bearing capacity of railway ballast, ensuring better track performance and longevity.

- Q: What are the geocell material options?

- The geocell material options include high-density polyethylene (HDPE), polypropylene (PP), and polyester (PET).

- Q: How do geocells help with soil stabilization?

- Geocells help with soil stabilization by confining and reinforcing the soil, preventing its movement and erosion. They create a stable and load-bearing structure that distributes the weight evenly, preventing soil settlement and supporting heavy loads. Geocells also improve soil quality by promoting root growth and providing effective drainage, ultimately enhancing the overall stability of the soil.

Send your message to us

HDPE Plastic Slope Erosion Geocells / Geocell Cellular Confinement System

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords