Plastic Geocell for Slope Protection with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Geocell for Slope Protection:

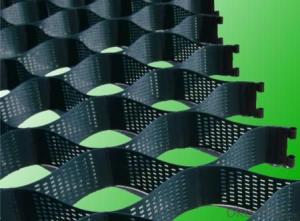

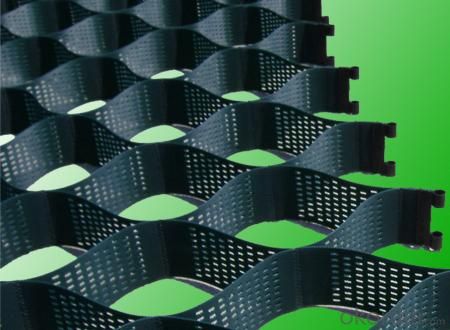

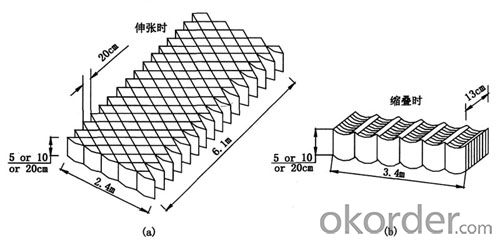

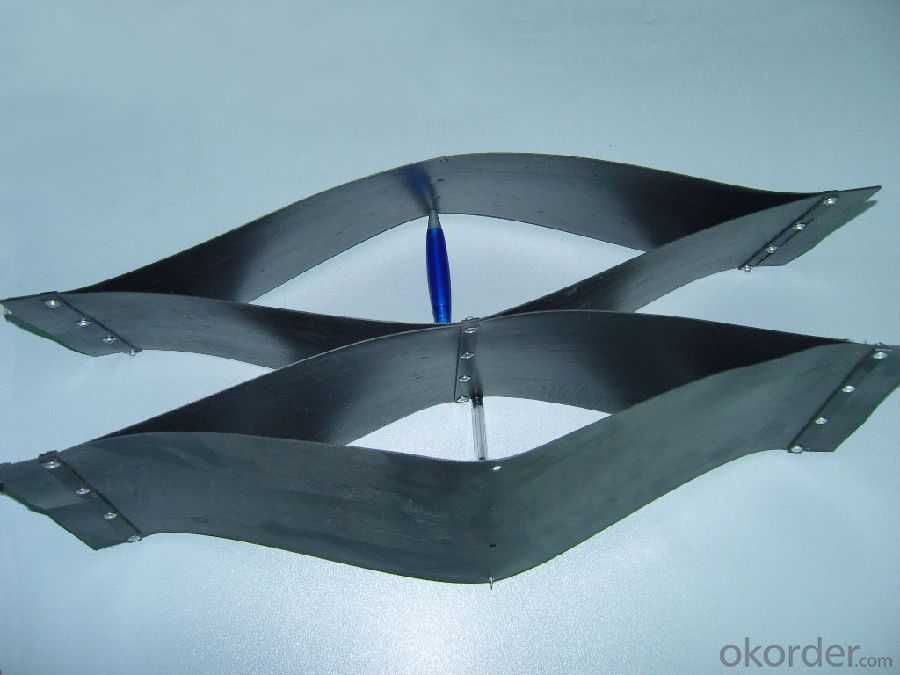

The product has the features of high-strength, durable, light weight. In process of construction, the geocell can be pulled into a honeycombed grid and then filled with various materials to provide a solution for erosion control, load support and earth retention projects. Therefore, it is widely used in stabling soft roadbed and bearing the load of dike.

Main Features of Plastic Geocell for Slope Protection:

1. flexible to fold during transportation, stretching out

2. filled with stone or concrete during service, forming into structure with powerful lateral confinement and rigidity.

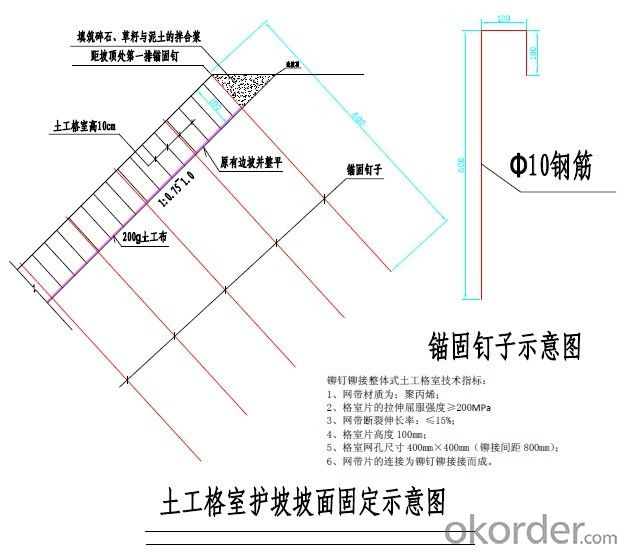

3. used as cushion coat to strengthen loading capacity of weak ground or slope protection structure

Specifications of Plastic Geocell/HDPE geocell:

1. Fix railway ground.

2.Fix weak ground of roads and increase loading capacicity.

4.used to build the support block struction

5.Act as independent wall, dock and break-water.

6.Treat desert, beach, riverbed and bank.

Geocell Product Poperties

| Height (mm) | Welding distance (mm) | Sheet thickness(mm) | Tensile yield strength of the cell≥(MPa) | Seam peel strength≥(N) | ||

| smooth | textured | |||||

| TGLG-50-400 | 50 | 400 | 1-1.1 | 1.4-1.5 | 20 | 500 |

| TGLG-100-400 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

| TGLG-150-400 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

| TGLG-200-400 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

| TGLG-75-330 | 75 | 400 | 1-1.1 | 1.4-1.5 | 20 | 750 |

| TGLG-100-330 | 100 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1000 |

| TGLG-150-330 | 150 | 400 | 1-1.1 | 1.4-1.5 | 20 | 1500 |

| TGLG-200-330 | 200 | 400 | 1-1.1 | 1.4-1.5 | 20 | 2000 |

Applications of Plastic Geocell/HDPE geocell:

*Erosion Control

*Load Support

*Slope Protection

*Channel Protection

*Retaining Wall

*Ground Stabilisation

now most of our products are exported to Chile,Mexico,Brazil, Argentina , Russia, Poland, Turkey, USA, UK, Iran,and etc.

IMages of Plastic Geocell/HDPE geocell:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are geomembranes resistant to algae growth?

- Yes, geomembranes are generally resistant to algae growth. They are designed to be impermeable and provide a barrier against water and other substances, which prevents the growth of algae. Additionally, geomembranes are often made from materials that are not conducive to algae growth, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC). However, it is important to note that proper installation and maintenance of geomembranes are essential to ensure their effectiveness in preventing algae growth.

- Q: Are geomembranes recyclable?

- Yes, geomembranes are recyclable.

- Q: What is the expected lifespan of a geomembrane in an oil storage facility?

- The expected lifespan of a geomembrane in an oil storage facility can vary depending on several factors such as the type and quality of the geomembrane material, the specific conditions and environment in the storage facility, and the maintenance and care provided. However, on average, a well-designed and properly installed geomembrane can have a lifespan of around 20 to 30 years.

- Q: How do geomembranes contribute to the prevention of slope instability?

- Geomembranes contribute to the prevention of slope instability by acting as a barrier that effectively controls water flow and seepage. By being installed within the slope, geomembranes intercept and redirect water, preventing it from infiltrating the soil and causing erosion. This helps to maintain the stability of the slope and prevents potential landslides or slope failures.

- Q: How to make geomembrane inspection?

- First laying: Overall consideration of reducing the seams and convenient construction, selecting the composite geomembrane of appropriate width, with single-sided margin of 10cm and neat scrapped edge. The debris on the ground should be cleaned up and the size, flatness and compactness of slope cutting site should be subject to the acceptance of supervising engineer before laying the geomembrane. Connection: Usually using sweat soldering method

- Q: What is geosynthetics reinforced base?

- When bases of buildings are constructed with soil (sandy material) and geosynthetics beneath the soil, the geosynthetics can be monolayer or multilayer with superficial layer foundations.

- Q: How to remove the protective film of the guard against theft?

- There are many methods: 1: The area is not large and you can use banana water to soak it and then clean it with a cleaning ball. 2: It can be removed with cleaning agents (bottled called A1) used in the textile industry.I have tried. It is very good. 3: To add some sulfuric acid into the water, otherwise it will be corroded and then rub with the cleaning ball. 4: To heat it with the electric?hair?drier, or with a wooden shovel, plastic marks can be used to wipe off the solvent oil

- Q: How to adhere film to the glass window?

- A. Preparatory work and installation of architectural membrane pasting: 1. Preparations before installation a) Learn the specific conditions of the window to be pasted membrane in detail, and estimate specific items for site cleaning, and the size and quantity of the window membrane needed cutting; b) Determine the construction?method according to the window membrane type chosen by the customer and characteristics of the the glass; c) Check whether the installation tools are normal, and check if the "blade" of the water wiper is flat and smooth, and if there is any gap existent. Check if the cleaning scraper knife is sharp, and if there is any gap or sawtooth existent; d) Check if the cleaning and installation towel is clean, if the waterproof membrane is clean and intact; e) Prepare the film-on and cleanout fluid well; 2. Installation of window membrane: A. Advance preparations for the construction site. a) In the construction site, remove the curtains, blinds, and all other objects near the window carefully, and make them go back to the original state when the window membrane installation is completed. Try to leave more space for equipment placement. If the construction site is located within an office or store, please make sure that the cleaning work in advance will not interfere with the customer's normal business operations; b) Do a good job in on-site waterproof and cleaning, laying of waterproof membrane, and work overalls and shoe covers wearing;

- Q: How are geomembranes tested for puncture resistance?

- Geomembranes are tested for puncture resistance using a standardized test method called the puncture test. This test involves subjecting the geomembrane to a sharp object, such as a needle or a cone, at a specified force or pressure. The force required to puncture the geomembrane is measured, and this data is used to evaluate its puncture resistance.

Send your message to us

Plastic Geocell for Slope Protection with CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords