Mactex Geotextile Plastic Gravel Stabilizer/Soil Stabilizer Geocell/Grass Soil Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Plastic Gravel Stabilizer:

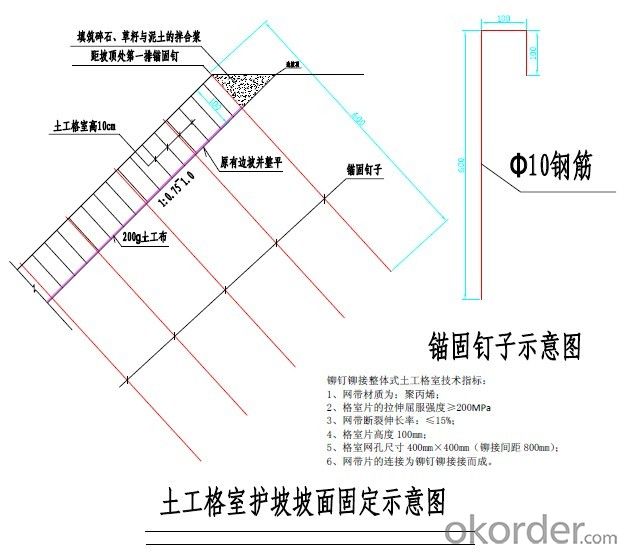

strength geosynthetics, which is popular in domestic and abroad. It is a kind of three-dimensional network structure shaped by high-strength HDPE sheets through ultrasonic welding of high strength. Currently, it is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Main Features of Plastic Gravel Stabilizer:

1 Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

2 Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

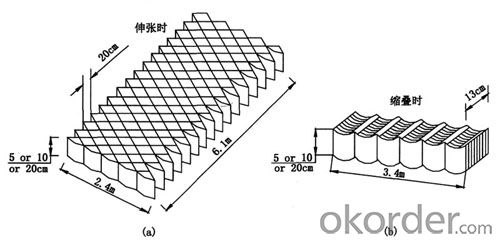

3 Size is relatively stable, change the height and welding distance can meet the needs of different projects.

4 Retractile, easy to transport.

5 Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

6 Can be used repeatedly.

Specifications of Plastic Gravel Stabilizer:

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(Mpa) |

Smooth and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Smooth and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.0~1.4 | ≥100 | ≥120 | ≥20 |

Textured and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Textured and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5~1.7 | ≥100 | ≥120 | ≥20 |

Remarks: 1. This is a basic technical specification. 2. All of the technical indexes can be reached according to the customers' demand, and the other special standards will be carried out by agreement or contact.

| ||||||

Applications of Plastic Gravel Stabilizer:

1 To stable the roadbed of highway/railway.

2 To bear the load of dyke, retaining wall.

3 To improve the watercourse of shallow river.

4 To support the pipeline and sewer.

5 To be used as independent wall, wharf and breakwater, etc..

6 To be used for the regulation of the desert, beaches, river bed and river bank.

7 Open the superimposed geocell.

8 Fixed with nails or connected with the framework of stretching device.

9 Fill the particle filler until the full and beyond standard room to the top, then vibrate or roll to finish the primary work.

10 At this point, cell chamber system can support all kinds of construction equipment. The construction can be done directly in the above.

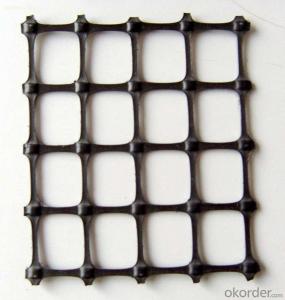

IMages of Plastic Driveway Paver Gravel Stabilizer:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What are the benefits of using geotextiles in erosion control?

- Geotextiles offer several benefits in erosion control, including their ability to prevent soil erosion, stabilize slopes, and promote vegetation growth. They act as a barrier against water flow, reducing the impact of rainfall and preventing sediment runoff. Geotextiles also enhance soil reinforcement by distributing load and reducing soil movement. Furthermore, they allow for better filtration and drainage, improving water quality and reducing the risk of flooding. Overall, geotextiles provide cost-effective and environmentally friendly solutions for erosion control.

- Q: How much is the price of anti-geotextile?

- In the actual engineering procurement, generally between the two geotextiles need about> 250px lap, so the procurement is usually based on the actual area plus 15% to 20% loss. Hongxiang new material Li Qian geotextile price is also required according to the specific needs of the project to specify the model, the specific offer.

- Q: Why lay the geotextile cloth after the gravel cushion

- This is to prevent the soil from slipping away

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: Are geotextiles commonly used in landfills for leachate collection?

- Yes, geotextiles are commonly used in landfills for leachate collection. They play a crucial role in containing and filtering leachate, preventing its migration into surrounding soil and water bodies. Geotextiles provide a permeable barrier that allows leachate to drain while retaining solid waste, ensuring effective management of landfill leachate.

- Q: How do geotextiles help with soil stabilization in slope stabilization projects?

- Geotextiles aid in soil stabilization in slope stabilization projects by acting as a barrier against erosion, reducing water infiltration, improving soil drainage, and enhancing soil strength and stability. They prevent the loss of soil particles, allow for proper water flow while preventing excess water accumulation, and provide reinforcement to the soil, thereby minimizing slope failures and promoting long-term stability.

- Q: Are geotextiles suitable for high-traffic areas?

- Yes, geotextiles are suitable for high-traffic areas. They are designed to provide stability, reinforcement, and filtration in soil and can effectively distribute loads. Geotextiles can help enhance the durability and longevity of high-traffic areas such as roads, parking lots, and walkways.

- Q: How do geotextiles contribute to soil moisture retention?

- Geotextiles contribute to soil moisture retention by acting as a barrier that prevents water from evaporating or being lost due to gravity. They allow water to permeate through the soil while preventing excessive drainage, thus promoting better moisture retention in the soil. Additionally, geotextiles also help to reduce soil erosion, which further aids in maintaining soil moisture levels.

- Q: Tunnel without sand concrete, geotextile, seepage blind pipe construction sequence

- In accordance with the order of seawater blind pipe geotextile sandless concrete, I specialize in producing geotextile materials

- Q: 800g / m2 non-woven geotextile vertical permeability coefficient is generally how much

- 800g / m2 non-woven geotextile vertical permeability coefficient is: 6.1 × 10-2

Send your message to us

Mactex Geotextile Plastic Gravel Stabilizer/Soil Stabilizer Geocell/Grass Soil Geocell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords