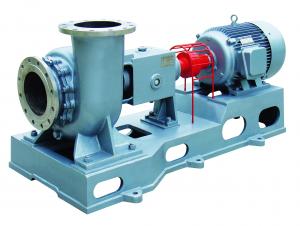

Single Stage Chemical Mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

ASP5620 series single stage、centrifugal chemicl mixed flow pump includes horizontal radial section,cantilever type.

The pump is safe,steady operation and easy to maintenance.

The pump is steady in hydraulic performance,high efficiency.

The pump can transmit liquid that is neutral or corrosive with large flow rate,low head,even or has some particles.

Sealing can be packing seal,single、double mechanical seal according to different condition.

Rotation direction:The pump rotates clockwise from the drive end.

Application Area

The pump can transmit liquid that is neutral or corrosive with large flow rate,low head,even or has some particles.

Irrigation and drainage equipment

Cooling water circulation system

City coal gas project

Forced circulation in chemical processing

Salt making and alkali making industry

Performance Range

Capacity Q ~7000m³/h

Head H ~25m

Work pressure P ~1.0Mpa

Work temperature t -20~140℃

Structural Characteristics

█ ASP series mixed flow pump is a “Pull-out”type pump.When examining and dismantling impeller and shaft seal,there is no need to disconnect the pipeline that is connected with the pump casing.Pump shaft is precision machined,and the bearing is thin oil lubrication.There is protective shaft sleeve in the stuffing box cover.The oil in the bearing box can be controlled by a constant oil cup.

█ Supporting foot of pump can bear any load coming from pipeline,and pass it to the foundation.Then the rotor can not bend because of the load of bearing to make sure the max. service life of bearing.

█Passing area is so large that it can reduce the blocking.

█Pump with specification 35-40,its outlet&inlet flange dimension complies with HG20592 Standard,pressure rating is 1.0Mpa;for the pump with much larger specification,its pressure rating is 0.6MPa.

█ Electric motor or internal combustion engine shall be used as the power drive.

█ A whole air bleeder shall be installed on the pump,which shall be good for the exhaust of suction pipe.

█ Sealing can be packing seal and double mechanical seal.

- Q: Fire hydrant pump button, under what circumstances do not need to install?

- General high voltage system, when normal, use small pump steady pressure.Fire hydrant button lifting pump is one of the multiple pumping methods, and it is an important link of reliable operation of the system.

- Q: Troubleshooting of diaphragm pump

- The troubleshooting guide for diaphragm pumps, when encountered in one or more of the following situations, this information can be used as a guide to help you develop maintenance measures.As shown below, some of the abnormal operating conditions described in this guide are: A) fast circulation / low flow B) no cycle / slow cycle / irregular cycle C) leakage D) noise E) component rupture

- Q: What should I pay attention to when buying a pump?

- Two, the first choice of large and medium-sized professional manufacturers, and through the quality identification of relevant departments, the market credibility of the better models, but also to the professional quality inspection institutions consultation.Three, check the motor grounding device for electric pump, water pump and motor axis, the motor should be in a proper position is provided with a grounding screw, and the grounding screw are arranged near the ground; grounding device of small submersible pump should be reliable and grounding wire, grounding wire cables should have the obvious grounding mark the flag should be in use; the motor is not easy to be worn during the period. This is one of the important safety indexes of electric pumps.

- Q: How to select metering pump head?

- In metering fluoride, we recommend the use of Viton, sealed PVC pump head. For most chlorination applications, it is better to use EPDM sealed NP (plexiglass) pump head. For hydrogen peroxide mixtures, only PTFE sealed PTFE pump head or stainless steel pump head can be used

- Q: Why can the centrifugal pump hold down the pressure?

- Centrifugal pumps are vertical, horizontal, single-stage, multi-stage, single suction, double suction, self suction and other forms. Vertical centrifugal pump is referred to as submerged pump, molten salt pump and submerged pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work.

- Q: Water pump does not produce water, what are the reasons?

- The reason why centrifugal pump does not produce water:1. pump inlet or sink, water tank water shortage.2. water pump pipe blocked or valve not open.

- Q: What is an industrial water pump?

- The pump has the different uses, conveying different liquid medium, different flow rate, different lift range, therefore, its structure of course is not the same, the material is different, in general, can be divided into:1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- The power of axial flow pump decreases with the increase of flow rate, and it is a steep curve, so the centrifugal pump starts with an open valve.

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- Compressed air source, the general pneumatic diaphragm pump starting gas source for 0.1~0.2mpa,The maximum working pressure is 0.7~0.8mpa, so in this pressure range, you can use the air filter relief pressure valve gas pipe, adjusting for air pressure, when the pressure is bigger, diaphragm movement faster, so the greater the flow, and vice versa

- Q: What's the submersible pump?What is a submersible pump, and what about it?

- Submersible pump is a pump directly on the water inside the pump, eliminating the water inlet pipe, eliminating the trouble of ordinary water, is very convenient, just a pool, pool, bucket, water tank water level is shallow to be able to work, meet your requirements of pumping drainage

Send your message to us

Single Stage Chemical Mixed Flow Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords