One component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

One-component polyurethane waterproof coating , also called the moisture-curing polyurethane waterproof coating, is a kind of reactive wet curing film waterproof coating. When using,it coat at the waterproofing basic level, through reacting and moisture in the air and got behind by the tenacity, soft and jointless rubber waterproof membrane.

Main Feature:

Excellent mechanical properties, low temperature performance, convenient construction, coat without seams, good adhesion and flexibility, convenient maintenance, etc.;

High solid content, no producing and precipitation of volatile substances in construcction and after construcction, no harm for the builders and the environment;

No need the ingredients, using out-of-the-box, no affecting measurement error and quality;

The color is adjustable to meet different customer human requirements for surface color.

Application:

Roof Waterproofing: Suitable for waterproofing various types of roofs, including concrete, steel structures, and wood substrates.

Basement and Floor Waterproofing: Used for waterproofing basement floors and walls to prevent groundwater infiltration.

Bathroom and Kitchen Waterproofing: Ideal for waterproofing floors and walls in wet areas such as bathrooms and kitchens.

Exterior Wall Waterproofing: Can be applied to the exterior walls of buildings, particularly suitable for waterproofing concrete and masonry structures.

Bridge and Tunnel Waterproofing: Suitable for waterproofing bridges and tunnels, protecting these structures from moisture and corrosion.

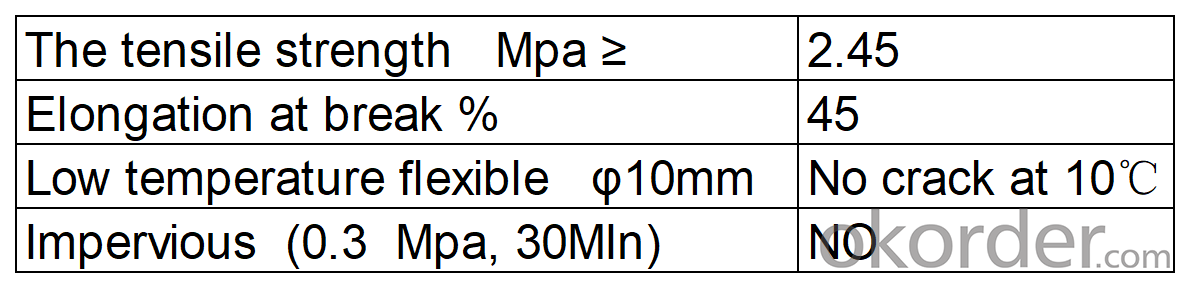

Specification:

Images:

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: Eastern rainbow waterproof how to do

- General family bathroom is brush JBL waterproof coating, buy back to the first dilution, and then clean up the ground with brushing uniform brushing, the bathroom should brush the ground and the wall 1.6 meters high,

- Q: What is PE waterproof cloth and PVC tarpaulin

- PVC (tarpaulin) Features: coated high-strength polyester waterproof cloth is a high-strength polyester canvas-based cloth, coated with polyvinyl chloride (PVC) paste resin with accelerator, anti-mildew agent, anti-aging agent, anti Electrostatic agents and other chemical additives, made by high temperature plastic. Waterproof, anti-aging, anti-static and other properties; and the product breaking strength, tear elongation, tear strength is much better than the traditional tarpaulin; product appearance colorful, it is pleasing to the eye. The surface of the special treatment from the anti-skid effect, is the international popular waterproof cloth, and the width of large, reaching 2 meters wide, processing products can reduce the patchwork to improve the quality, can be used to heat sealing stitching, The And according to user needs to produce different functions, different colors, different thickness of the product.

- Q: Find the construction steps for waterproof coatings

- 3, note (1) rain weather and five wind above the weather shall not be construction. (2) coating waterproof layer shall not have bottom leakage, cracking, holes and other defects and peeling, bubbling, carcassing and wrinkle phenomenon. Coating waterproof layer and the base should be bonded between the solid, no hollowing, trachoma, delamination and so on. (3) the coating site should be continuous, solid, shall not appear Alice, hollowing parts. (4) rigid protective layer before the completion of any personnel shall not enter the construction site, so as not to damage the waterproof layer; coating of the overlapping parts should be care by the staff. (5) roof should be used lime soil, clay or sub-clay for backfill, thickness 50 cm, backfill shall not contain stones, gravel, ash and organic matter. Artificial compaction of each layer 25 cm, mechanical compaction of each layer 30 cm, rammed to prevent damage to the waterproof layer. In the backfill thickness of more than 50 cm, it is allowed to use mechanical backfill rolling.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- If you are out of the finished line, the best anti-static that can! I plant is the production of waterproof material, in addition to the internship when I went to the workshop, and now I do not go!

- Q: Nanning building waterproof material market where

- to buy what materials are going to go to some factories, such as paper, printing materials and other manufacturers in the Nanning High-tech Zone or Nanning Economic Development Zone may be more

- Q: I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Second, check the plaster layer is empty, if not empty easy to use polyurethane brush twice, the surrounding multi-coated 10 cm. If the empty drum, then use the cutting machine to remove the plaster within the scope of the plaster, along the cracks on both sides of the expansion of 10 cm brush twice the polyurethane, brush the cement slurry and then do the surface layer. If a large area of ??leakage, it is recommended to use acrylic waterproof coating brush twice, because the polyurethane black too heat in summer affect the indoor temperature.

Send your message to us

One component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords