Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

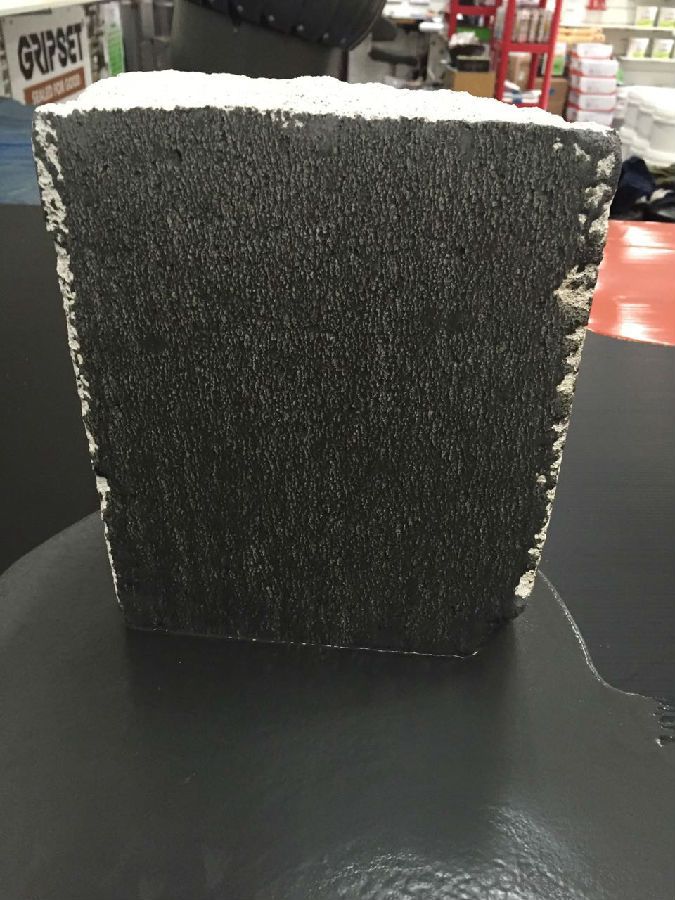

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: How to do waterproof bathroom, construction process is what

- 4, closed water test. Closed water test, the highest point of the ground water can not be less than 2 cm, save at least 24 hours, observe the phenomenon of no leakage after the operator. If there is leakage, need to redo, and can not neglect.

- Q: What is PE waterproof cloth and PVC tarpaulin

- PE tarpaulin, anti-aging, anti-aging, anti-corrosion, light, easy to fold, relative to the PVC tarpaulin, PE tarpaulin cheaper price for the freight yard, the service life will be shorter.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 3, according to the hydrogeological conditions and outdoor environment type to take the appropriate level of waterproof concrete.

- Q: What material is used for waterproofing of tarpaulin

- Cement-based waterproof paste (such as the Swiss Sika) Product category Cement-based materials non-toxic, environmentally friendly, both in the construction process also Is formed after the harmless to humans and animals.

- Q: Roof membrane waterproof construction process, what should be noted that?

- Coil ply attention Paving direction, slope less than 3%, parallel and roof paving, slope greater than 15% or roof vibration, perpendicular to the roof paving. Slope between 3% to 15%, can be parallel to the vertical; membrane waterproof roof slope should not be greater than 25%. The upper and lower layers may not be piled on each other.

- Q: Js waterproof coating without powder can brushing

- 2. Mixing and mixing: JS waterproof coating: cement = 1: 0.8 weight ratio of mixing, fully stirred to no particles, uniform mortar can be used; in the course of the application to adhere to intermittent mixing, to prevent layered deposition ;

- Q: There is no formaldehyde in the finished putty

- The current status of the market to buy regular manufacturers out of semi-finished products putty and formaldehyde has nothing to do, because the status quo countries also hit the product containing formaldehyde in the building materials, the current market traffic is relatively large for the water putty, putty powder which is natural mineral powder And water-based glue synthesis, because the product life long-term pollution-free, so that is impossible to contain formaldehyde, but engineering putty is usually on-site modulation, and in order to increase the adhesion of putty powder inside the addition of a large number of construction glue (Containing formaldehyde).

- Q: Roof for the insulation, Master roof, using two waterproof construction program

- Third, security measures 1, firmly establish the "safety first, prevention first" safety production policy. Before the operation, the site management personnel must be to the operation team to carry out security technology to the end, and actively carry out pre-class security activities, security personnel check, supervise. 2, the roof around the poles outside the scaffolding (protective railings), roof construction is strictly prohibited removal. 3, roof construction, debris and other materials is strictly prohibited from the roof directly down throwing. 4, storage of coils and adhesives warehouse or site to prohibit the fireworks, for the use of fire, there must be fire prevention measures, and should set a certain number of fire extinguishers and sand bags. 5, oil drums should be flat, not two carrying, in the transport process, pay attention to balance, the spirit to focus, to prevent accidental fall caused harm. 6, transported to the roof of the material, should be scattered on average, with the use of transport, not concentrated stacking. 7, the use of torch, you should clear the surrounding flammable items, must be away from the base of oil, is strictly prohibited in the brush base oil area using the torch. Torch petrol should not be over full, cheer should not be too much, in the fire site must be equipped with fire equipment.

- Q: How can the toilet waterproof works fail?

- After the failure of the bathroom waterproofing project to solve the specific needs of the specific analysis of targeted treatment. ??????? Bathroom waterproof is the problem more decoration works. The main reasons are: 1, construction (local, details, etc.); 2, waterproof material problems; 3, the structure (such as uneven settlement, cracking, etc.); 4, to save a little waterproof waterproof measures. ???????? After the three must be redo waterproof, the first type of reasons can be used to the appropriate remedial measures, pay the table "bathroom waterproof failure part of the phenomenon and the remedy list." ??????? Please responsible professionals in the field to carefully check the judge to find specific reasons for dealing with the need to destroy the red or must be destroyed, do not affect others after causing greater losses. The following are the same as the "

- Q: Roof sunscreen waterproof layer leakage, brush milk white plastic can solve it?

- Fourth, for some of the construction of the roof of the cover of Hong Kong leakage, as long as the removal of tiles on the grass, moss or dust after the replacement of tiles, leak-proof effect is the same. For flat roofs, the roof of the obvious cracks, with the tool will be cracked into a "V" or "U" shape, filling the caulking ointment, filled with cracks and above the use of waterproof wrap around the package. To strengthen the leak-proof effect, you can also shop a layer of waterproofing membrane. ? ???Roof leakage how to deal with five, most of the use of clean up the roof, crack filling, crack sealing, mortar to find equal maintenance methods. Waterproof methods are: membrane waterproof, rigid waterproof, flexible waterproof, waterproof coating and other methods. You can also use the plugging the king is better, for the seepage, slightly dug the slot can be directly plugging the dry powder into the tank, compaction, wiping, sprinkler can be maintained. If the investigation is your home to leak water, the main problem should focus on the surface of the leakage interface and the upper part of the section, it is recommended to find professional leak-proof, it is estimated that it is to spend tens of dollars, if you want to repair it To buy a waterproof paint, (the specific name of a lot to go to that kind of store that they know) and then painted in the floor drain and toilet under the mouth of the water pipe and the upper section can be.

Send your message to us

Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords