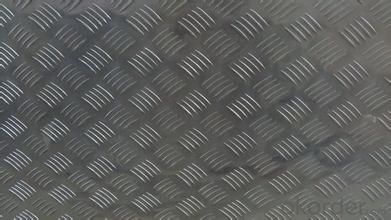

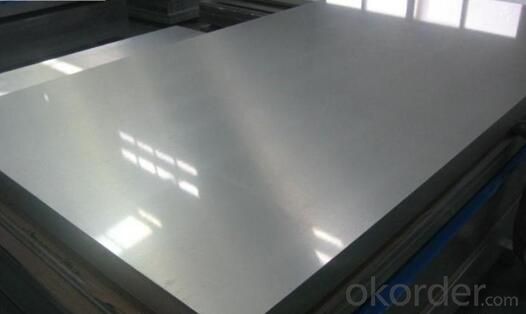

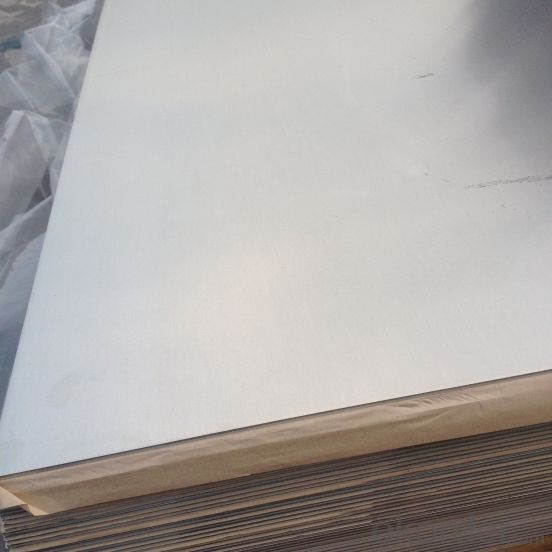

Wholesale Silver Brushed Aluminum Wall Sheets for Kitchen Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

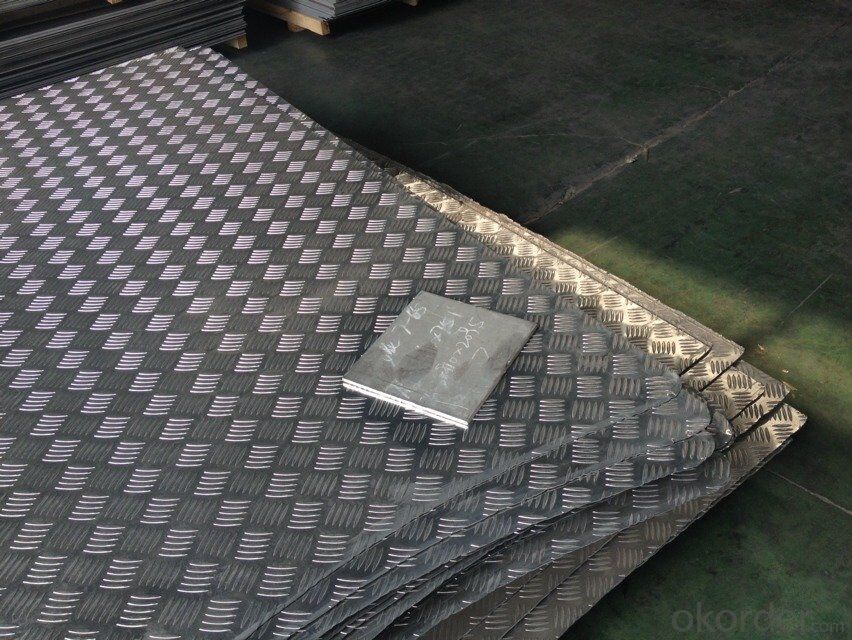

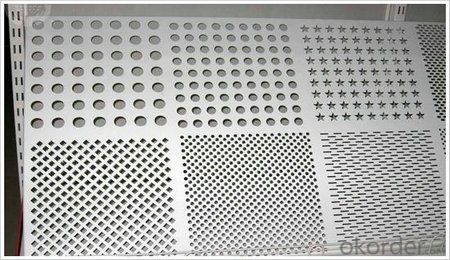

Aluminum Sheets

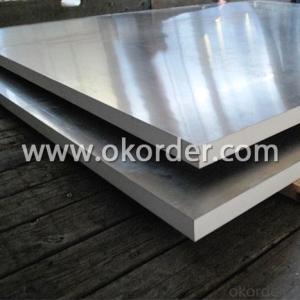

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

1.Dark green surface, color changed into light green after exposure.Image checked easily.

2.Surface Quality :be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

3.Faithful reproduction capacity, result at clear images.

4.Highly durable, long impression available.

5.Excellent sensitive character.

6.Resolution : 2%-98%

7.Material:1050/1060/1070/1100/2A16/2A06/2A12/2024/3003/3A21/4A01/5052/5005/5083/5A05/6061-T6/6063-T5/6082/7021/7075-T6/8011,etc

8.Certificate: ISO9001:2000, SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO)

9.Packing:First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation,wooden pallets

10.Application:Aircraft, automobile, train,Building wall, ceilings, roofing, furniture cabinet, lighting plate,etc

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- I also want to know how to protect the factory

- Q: Are aluminum sheets suitable for food processing applications?

- Aluminum sheets are indeed suitable for food processing applications. The reason behind their popularity in the food processing field lies in their outstanding properties, which include corrosion resistance, thermal conductivity, and low reactivity with food substances. These sheets find widespread use in a variety of food processing equipment, such as storage containers, cooking utensils, and packaging materials. Moreover, aluminum sheets are lightweight and easy to clean, while also possessing excellent heat distribution properties. This makes them ideal for applications that necessitate precise temperature control during food processing. Furthermore, the use of aluminum ensures food safety and prevents any potential contamination, as it is a non-toxic material. All in all, aluminum sheets are a dependable and extensively employed material within the food processing industry.

- Q: I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- 1. Crack type: longitudinal crackFeatures: by table and depthShape conditions: hardenability of the workpiece, easy to produce raw materials, carbide band segregation or non-metallic inclusions extensionPreventive measures: control raw material quality, select preheating treatment, improve original organization2. Crack type: net crackFeatures: located on the surface of the workpiece, depth 0.01 ~ 2mmSurface conditions: surface decarburization, heat treatment, surface hardening, easy to presentPrevent measures: take heating protection, avoid decarburization, delay quenching cooling, reduce quenching temperature3. Crack type: arc crackFeatures: located at the corner of the workpiece, hidden in the surface layerShape conditions: prone to Weicui through the workpiece or carburized partsPreventive measures: change workpiece design, cross section fillet rationalization4, crack type: peel crackCharacteristic: showing the delamination of hardened layerShape condition: surface hardening parts or heat treatment partsPrevention measures: reasonable choice of medium, delay cooling5. Crack type: microcrackFeatures: defects in microstructureShape conditions: hardening of high carbon martensite nearPreventive measures: avoid heating, hot, coarse grain

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is generally considered to be excellent. Aluminum is a highly malleable metal, meaning it can be easily shaped or formed into various designs without cracking or breaking. This characteristic makes aluminum sheets highly desirable for a wide range of applications, including automotive body panels, aircraft components, and household appliances. Additionally, aluminum has good ductility, which allows it to be stretched and bent without losing its structural integrity. However, it is important to note that the formability of aluminum sheets can vary depending on the alloy composition, thickness, and processing conditions. Therefore, it is essential to consider these factors when choosing the appropriate aluminum sheet for a specific application.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Yes, aluminum sheets can be anodized without significantly affecting their dimensions. Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, which improves its corrosion resistance and durability. The anodizing process involves immersing the aluminum sheet in an acid bath and passing an electric current through it. This causes the aluminum to oxidize, creating a layer of aluminum oxide on the surface. During the anodizing process, the aluminum oxide layer grows inward into the metal, while also building up on the surface. The growth of the oxide layer is controlled by the duration of the anodizing process, and it can be precisely controlled to achieve the desired thickness. Therefore, the dimensional changes caused by anodizing are minimal and can be easily accounted for in the design phase. However, it is important to note that anodizing can cause a slight increase in the thickness of the aluminum sheet. This is due to the growth of the oxide layer on the surface. Typically, the increase in thickness is around 50% of the overall oxide layer thickness. For example, if the desired oxide layer thickness is 10 micrometers, the overall increase in sheet thickness would be approximately 5 micrometers. In summary, while anodizing aluminum sheets can cause a slight increase in thickness, the dimensional changes are minimal and can be accurately predicted and accounted for in the design phase. Anodizing is a popular and effective method for enhancing the properties of aluminum sheets without significantly affecting their dimensions.

- Q: This question asks for methods to determine the thickness of aluminum sheets.

- <p>To measure the thickness of aluminum sheets, you can use various methods including mechanical thickness gauges, ultrasonic thickness gauges, or calipers. Mechanical gauges are simple and involve sliding a foot along the sheet until it bottoms out on both sides. Ultrasonic thickness gauges use sound waves to measure thickness and are non-destructive, providing accurate measurements. Calipers can also be used for manual measurement, though they may be less precise for very thin sheets. Always ensure the measuring device is calibrated and suitable for the material and thickness range of the aluminum sheet in question.</p>

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- The main advantage of fiberglass ladders is the reduction of electric shock from contact with electric wires. A disadvantage of fiberglass ladders is the tendency of fiberglass to crack. The inverse of this applies to aluminum. I bought a Little Giant ladder; it is a 300lb rated aluminum ladder with great stability and can function as a 12' step ladder and a 21' extension ladder. It cost me over $400, but after using it for over a year I would not buy any other kind regardless of the price. This is a solid, well-made ladder with great versatility. It also comes in smaller versions; I think the smallest one collapsed takes up only about 5 feet of space.

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable. Aluminum is a highly recyclable material, and the recycling process for aluminum sheets is relatively simple and efficient. Recycling aluminum sheets involves melting the metal down and reforming it into new sheets or other aluminum products. The recycling process for aluminum requires considerably less energy compared to the production of new aluminum, making it an environmentally-friendly option. Additionally, recycling aluminum sheets helps conserve natural resources and reduces the amount of waste sent to landfills. Therefore, it is encouraged to recycle aluminum sheets whenever possible to contribute to a more sustainable and eco-friendly future.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

Send your message to us

Wholesale Silver Brushed Aluminum Wall Sheets for Kitchen Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords