Ceramic Filter Plate Silicon Carbide Foam Filter Series PPI10,20,30

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

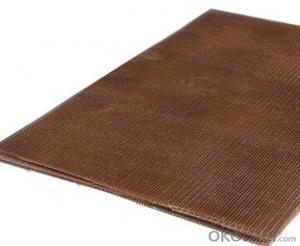

Ductile, Grey Iron, Vermicular Cast Iron and some Iron Alloy,and also for filtrating non-ferrous alloy, such as Cooper alloy and Aluminum alloy. It can remove impurities efficiently, and make metal filling steady in mould. It can also reduce air flow and casting impact in mould, and decrease pin hole, sand hole defeats to increase casting quality and product rate.

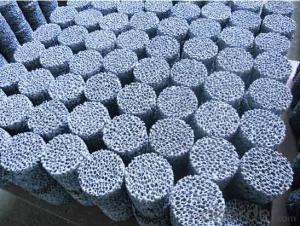

JG-202 Silicon Carbide Foam Filter

These series of products are newest products, which are produced through special material formula and latest advanced technology. Compared with normal ceramic foam filters, these new series products can be used at a higher temperature, which have higher strength at room temperature and high temperature. The physical property of this special material enables JG-202 series filters to have a better thermal shock resistance. They are suitable for harsh casting condition, such as placing on the bottom of vertical runner and casting at high temperature.

JG-203 Silicon Carbide Foam Filter

This product is produced through special material formula, and it has good durability, high thermal shock resistance and high porosity. It is mainly applied in filtrating heavy castings and medium-large casting, such as windmill, machine tool, ship parts and large part of mechanical equipment, etc.

Parameters

TypeMaterialsCompressive

Strength (Mpa)Porosity (%)Bulk Density

(g/cm3)Applied Temp.(≤℃)

JG-201SiC≥1.280-900.40-0.551500

JG-202≥1.578-900.45-0.601550

JG-203≥2.078-900.45-0.601500

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- At this time, take the filtrate (this is not the first water slurry) will pollute the ceramic filter pipe, friction ring, filtrate pump, may damage the vacuum system, remaining in the pipeline in the pulp will recoil pressure under the action of pollution caused by the other ceramic plates, ceramic plates blocked him. Once the ceramic plate is broken (depending on the severity), it will make the vacuum distortion, resulting in ceramic filter suction effect worse or even no suction!

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Ceramic filter plate.The ceramic filter plate does not match the blockage or selection of new plate porosity is generally around 40%, such as ceramic filter plate has hole blocking, the opening rate will become less, when the suction effect into 30% relatively new plate may be slightly worse, when the ceramic filter plate is used for a long time after the opening rate is 10% or less, then the ceramic filter plate suction effect will become very poor even suction. At this time, even if the vacuum suction is good, also do not suck sizing, you need to replace the new ceramic filter board.

- Q: Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

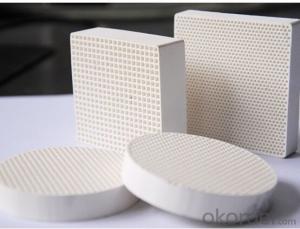

- Q: What are the functions of honeycomb ceramic filters?

- High quality and high density straight hole mesh, the product has high heat resistance and impact resistance properties of cast high fever temperature, design straight hole to guarantee the balance between strength and flow, effectively remove impurities and slag particles, the mechanical properties of casting, the surface quality and the qualified rate of products is greatly improved.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

Send your message to us

Ceramic Filter Plate Silicon Carbide Foam Filter Series PPI10,20,30

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches