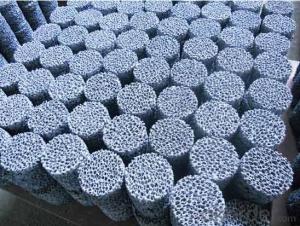

Ceramic Filter Plate - Ceramic Foam Filter Silicon Carbide

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter

Silicon Carbide Ceramic Foam filter is justdeveloped as a new type molten metal filter to decrease casting flaw in recentyears. With its characteristics of light-weight, high mechanical strength,large specific surface areas, high porosity, excellent thermal shock resistance,erode resistance, high-performance, siliconcarbide ceramic foam filter is designedfor filtering impurities from molten Iron & Alloy, nodular cast ironcastings, grey iron castings and malleable castings, etc.

CNBM silicon carbide ceramic foamfilter ischaracterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metalfiltrated, ceramic foam filter is machined to tight dimensionaltolerance during production, this combination of physical properties andprecise tolerance make them first choice for iron molten metal filtration.

TechnicalData of Silicon carbide ceramicfoam filter

BoreDensity(PPi) 10-40

Porosity(%) 80-90

Highestworking temperature (°C) 1500

BendingStrength (Mpa) 0.8

CompressionStrength(Mpa) 0.9

Thermal ShockResistance (times/1100°C) 6

DirectionsFor Use silicon carbide ceramic foamfilter

a) Dimensions Available:

Square shape:30-600mm

Round shape:φ40-φ300mm

Thicknessesfrom 10-50mm.

PPI:10P,15P,20P,25P,30P,40P

Ductile ironcastings use 10PPI, grey iron castings and tenacity iron casting use10PPPI,15PPI or 20PPI.

b)Filterable Melt Metal Weight Of Grey And Ductile Iron (10PPI):

Dimension | Ductile Iron (≤ kg) | Grey Iron (≤ kg) | metal volume of pouring (kg/sec.) | |

Ductile Iron | Grey Iron | |||

40×40×22 | 30 | 65 | 3 | 4 |

50×50×22 | 55 | 100 | 4 | 6 |

75×50×22 | 75 | 150 | 6 | 9 |

75×75×22 | 100 | 220 | 9 | 14 |

100×50×22 | 100 | 200 | 8 | 12 |

100×100×22 | 210 | 420 | 16 | 25 |

150×150×22 | 450 | 900 | 36 | 50 |

Weclome your enquiry about silicon carbide ceramic foam filter at any time. We are willing to supplyyou superior filters in most competitive price with professional service.

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: What's the reason for high water content in filtration copper concentrate?

- Vacuum: about -0.08MPaIf the vacuum required to consider other factors; such as the vacuum degree is not up to even only about -0.05MPa, it should be related to pipeline inspection of vacuum system leakage, vacuum pump damage, distribution valve failure, ceramic plate breakage, ceramic plate connecting pipe leakage may cause the vacuum is not up to, to achieve early detection and early treatment.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- One is leakage, two is no liquid output or output weakness, pressure is too low, cleaning effect is not good, the pressure is too large, will cause damage to the filter plate and reduce the slurry concentration. The recoil pressure is regulated by the pump loop valve and the pressure regulating valve.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

- Q: Can the ceramic plate filter the hot air?

- The cleaning of the ceramic filter is divided into two parts: reverse flushing (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board. Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure. Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.). Other reasons such as 1,2,3 are normal, but can not be discharged from the spindle speed too fast, even the ceramic filter itself manufacturing defects, the user equipment modification and so on, are likely to lead to abnormal operation of equipment. We specialize in ceramic filter boards for many years and welcome exchanges.

Send your message to us

Ceramic Filter Plate - Ceramic Foam Filter Silicon Carbide

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords