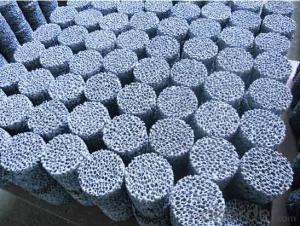

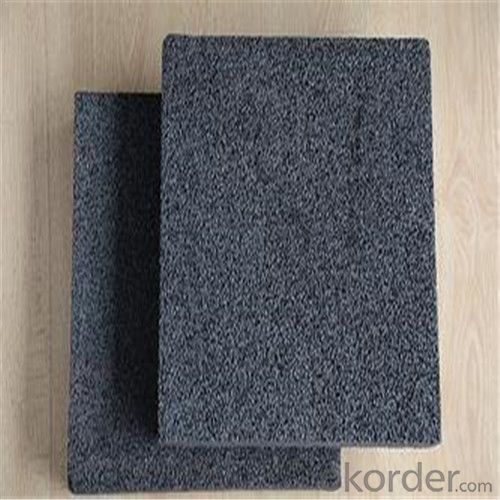

High-Quality Ceramic Filter Plate Silicon Carbide Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Silicon Carbide Ceramic Foam Filter for Foundry Industry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: |

Packaging & Delivery

| Packaging Details: | standard seaworthy/airworthy export packing |

| Delivery Detail: | 3 weeks |

Specifications

Silicon Carbide Ceramic Foam Filter work at more than 1500 Degree Celsius, filter moten iron and copper in related casting.

Silicon Carbide Ceramic Foam Filter

Ceramic Foam Filter is the third generation filter, compared with traditional filtering materials(ceramic honeycomb filter, extruded filter), our Ceramic Foam Filter have the advantages as below:

Silicon Carbide Ceramic Foam Filter Technical specification

Type Items | KFF-1 | |

Material | SiC | |

Working Temperature | 1500°C | |

Physical Properties | Porosity% | 80~90 |

Compression | ≥0.9Mpa | |

Volume Density | ≤0.6g/cm3 | |

Thermal Shock Resistance | 1100°C--Room Temperature ≥6 times | |

Main Chemical Content | Al2O3 | ≤30% |

SiC | ≥60% | |

SiO2 | ≤10% | |

ZrO2 | - | |

Others | 0~1% | |

Dimension | Round Shape | Φ30~Φ300mm |

Square Shape | 30~320mm | |

Thickness | 11~50mm | |

Pore Size | ppi | 8~40ppi |

mm | 0.1~15mm | |

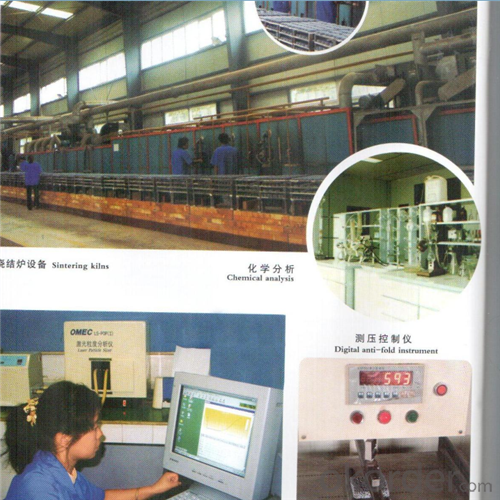

Others about US:

- Q: What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Ceramic filter plate.The ceramic filter plate does not match the blockage or selection of new plate porosity is generally around 40%, such as ceramic filter plate has hole blocking, the opening rate will become less, when the suction effect into 30% relatively new plate may be slightly worse, when the ceramic filter plate is used for a long time after the opening rate is 10% or less, then the ceramic filter plate suction effect will become very poor even suction. At this time, even if the vacuum suction is good, also do not suck sizing, you need to replace the new ceramic filter board.

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: Common troubles of ceramic filter

- (1) low vacuum, can not meet the production requirements. The main reason is the vacuum pipeline leakage, vacuum pump circulating water is not enough, vacuum pump impeller wear and tear, distribution head wear, ceramic filter plate damage, filtrate tank drainage valve is not closed, pulp trough material level is lower;(2) low or fluctuating backwash water pressure. The main reason is the blockage or leakage of the backwash water pipe system and the distribution of head wear;(3) the liquid level of the filtrate tank is high. The main reason is that the circulating water pump impeller or pump shell wear, pressure is insufficient, so that the drain valve can not open or drain valve itself failure, and filter barrels and circulating water pipe between the leakage;

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: Ceramic filter cleaning, sulfuric acid cleaning

- Can be washed with chromic acid lotion. The effect is better

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

Send your message to us

High-Quality Ceramic Filter Plate Silicon Carbide Ceramic Foam Filter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 g/m²

- Supply Capability:

- 1000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches