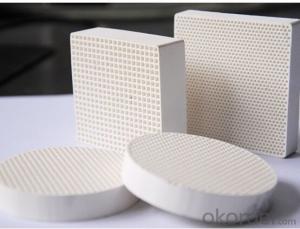

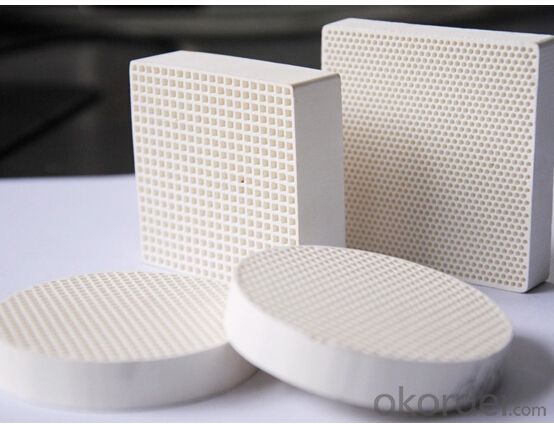

Foam Air Filter Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramicfoam filter is a kind of effective molten metal filter. It’s three-dimensionalconnected mesh skeleton structure and high porosity makes it has manyadvantages,large surface area of slags collection,largeinner surface area of filtering,Small flow resistance,goodfiltering effect,etc.

Functions of ceramic foam filter

decontaminatethe melting metal liquid,Simplified gating system,Improve casting qualityrate,Reduce casting internal re-oxidation defects.Reduce the surface defectsafter machining of the castings

Physical and Chemical Properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys like Steel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

For Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

For Iron Casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

For Steel casting

Dimensi | Zirconia Foam Filter | |

Pouring Rate(kg) | Filtration Capacity(kg) | |

50×50×22 | 3~5 | 30 |

50×75×22 | 4~6 | 40 |

75×75×22 | 7~12 | 60 |

75×100×22 | 8~15 | 80 |

100×100×22 | 14~20 | 100 |

50×22 | 2~6 | 18 |

80×22 | 6~10 | 50 |

90×22 | 8~16 | 70 |

- Q: What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: What's the reason for high water content in filtration copper concentrate?

- Ceramic filter plate1) the service life of the ceramic filter plate has arrived.2), ceramic filter plate uneven in quality on the market, the production capacity of some ceramic products difference (table mask size is too large or pore size uniformity is poor as a result of suction effect is poor, short life), but the price is low, but some users in order to reduce the operation cost of ceramic machine, tend to choose low price the ceramic plate, sometimes a ceramic machine ceramic filter plate with several may be different, so do not get the expected effect in normal use.In addition, the concentrator slurry, especially metal slurry, is very powerful on the wear of ceramic filter plate, the mechanical strength and wear resistance of ceramic filter plate requirements (corundum has high mechanical strength, good abrasion resistance, especially suitable for metal slurry dehydration).When selecting ceramic filter boards, these two points should be taken as a reference.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: What are the reasons for the program alarm of ceramic filter?

- The vacuum failure may be the vacuum pump failure, the vacuum pipeline leakage, the ceramic filter plate rupture or the connection water leakage, the backwash system is generally before the filtration water pressure is insufficient, the filter core plug and so on. Vacuum suction deficiency will lead to poor effect or even suction; cleaning standards will accelerate the ceramic filter clogging, ceramic filter clogging even if the vacuum suction is normal, will not even bad effect such as cake, jelly thin with high water content. Ceramic filter plate, hole plugging, discarding. Ceramic filter plate is life, under normal circumstances is about a year, such as pulp mud content, fine particle size or containing ingredients, cleaning is not easy to precipitate standards will reduce its life, when the ceramic filter plate close to the scrap, the suction effect will be worse. I hope my answer can help you.

- Q: What is the backwashing pressure of the ceramic filter?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

Send your message to us

Foam Air Filter Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords