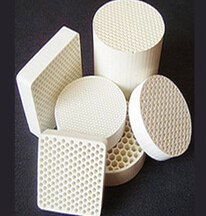

Specifications

1.. Large surface area2. Large void ratio

3. Low pressure

4. High temperature resistance

5. Stable chemical function

The honeycomb ceramic substrates are coated by catalyst;at the same time , we improve the specific surface areas and cut down the heat capacity to increase the catalytic function. When the noxious emissions pass through, HC, CO and NOX will be converted into harmless components.

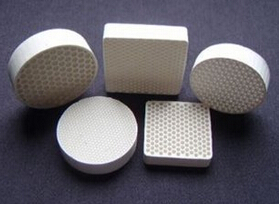

Composition | Value% |

SiO2 | 48% |

Al2O3 | 37% |

MgO | 13% |

Fe2O3 | <1% |

Other | <1% |

Bulk Density | 0.5-1.15g/cm3 |

Thermal Expansivity(20-1000°C)* 10-6°C | <2-7 |

Thermal Conductivity(1000°C(w.cm.k)-1)) | 1.0-1.40 |

Compression Strength KMP | 9.0-40 |

Refractoriness | 1580-2000°C |

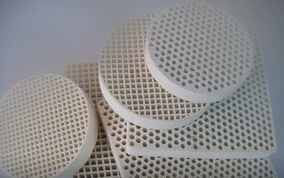

The necessary property of honeycomb ceramic catalyst substrate used in cars as follows:

1.High specific surface area: ensure exhaust gas could contact weigh catalyst enough.

2.Stable water absorption: guarantee catalyst could be firmly and evenly coated on the surface of substrate, so it's no waste for too thick coating.

3.Warm up characters: after starting up engine, the temperature of substrate could reach the active temperature of catalyst in the shortest time.

4.Low exhaust resistance: ask exhaust resistance of substrate to engine low, so that it won’t affect the performance of engine.

5.High intensity: substrates work in bumpy cars, so the intensity of substrates must be too high to be destroyed.

6.Perfect assembly: substrates are parts of exhaust; perfect appearance and exact dimension could ensure assembly perfect.