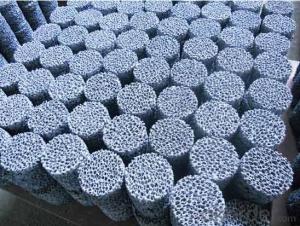

High Strength Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filters

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Ceramic Foam Filter :

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions slag and dross from the molten metal stream.

2.Main features of Ceramic Foam Filter:

◆ Excellent thermal shock resistance

◆ Good strength under high temperature

◆ Improving casting quality

◆ Reducing turbulence in gating system

◆ Tailored sizes as customers requirement

3. Ceramic Foam Filter Images:

4. Ceramic Foam Filter Technical Parameters

There are four kinds of ceramic foam filter according to different usages.

They are Silicon Carbide Ceramic Foam Filter, Zirconia Ceramic Foam Filter, Alumina Ceramic Foam Filter, Magnesia Ceramic Foam Filters.

Application

Grey iron casting, ductile iron casting, precious metals casting

Copper casting, bronze casting, brass casting

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our ceramic fiber products?

A world class manufacturer & supplier of ceramic fiber product is one

of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 80000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: What is the working pressure of the ceramic filter?

- Vacuum pressure or suction is the vacuum of the equipment, the size of the vacuum directly affects the effect of ceramic filter board suction (yield and water content). The vacuum system of ceramic filter consists of vacuum pumps, tanks, distribution device, ceramic filter plate and a connecting pipe is composed of ceramic filter, the vacuum pump is generally 2BV series water circulation pump, the vacuum pump vacuum limit is -0.097MPa, using a vacuum pump for a long time or vacuum system has poor sealing performance may cause a certain degree of vacuum distortion, so the ceramic filter vacuum is generally difficult to achieve in the -0.097MPa, -0.08 ~ 0.097MPa, which indicates that the vacuum degree is good, such as the vacuum degree is not up to -0.07MPa or less, the vacuum system may be an exception.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: What is the reason that ceramic filter does not absorb mineral powder?

- There may be a failure of the filtrate pump, the diaphragm of the pump is damaged, and the mechanical seal of the pump is invalid

Send your message to us

High Strength Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filters

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords