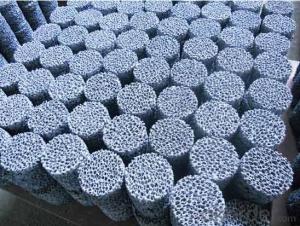

High Performance Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter

Silicon Carbide Ceramic Foam filter is justdeveloped as a new type molten metal filter to decrease casting flaw in recentyears. With its characteristics of light-weight, high mechanical strength,large specific surface areas, high porosity, excellent thermal shock resistance,erode resistance, high-performance, siliconcarbide ceramic foam filter is designedfor filtering impurities from molten Iron & Alloy, nodular cast ironcastings, grey iron castings and malleable castings, etc.

CNBM silicon carbide ceramic foamfilter ischaracterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metalfiltrated, ceramic foam filter is machined to tight dimensionaltolerance during production, this combination of physical properties andprecise tolerance make them first choice for iron molten metal filtration.

TechnicalData of Silicon carbide ceramicfoam filter

BoreDensity(PPi) 10-40

Porosity(%) 80-90

Highestworking temperature (°C) 1500

BendingStrength (Mpa) 0.8

CompressionStrength(Mpa) 0.9

Thermal ShockResistance (times/1100°C) 6

DirectionsFor Use silicon carbide ceramic foamfilter

a) Dimensions Available:

Square shape:30-600mm

Round shape:φ40-φ300mm

Thicknessesfrom 10-50mm.

PPI:10P,15P,20P,25P,30P,40P

Ductile ironcastings use 10PPI, grey iron castings and tenacity iron casting use10PPPI,15PPI or 20PPI.

b)Filterable Melt Metal Weight Of Grey And Ductile Iron (10PPI):

Dimension | Ductile Iron (≤ kg) | Grey Iron (≤ kg) | metal volume of pouring (kg/sec.) | |

Ductile Iron | Grey Iron | |||

40×40×22 | 30 | 65 | 3 | 4 |

50×50×22 | 55 | 100 | 4 | 6 |

75×50×22 | 75 | 150 | 6 | 9 |

75×75×22 | 100 | 220 | 9 | 14 |

100×50×22 | 100 | 200 | 8 | 12 |

100×100×22 | 210 | 420 | 16 | 25 |

150×150×22 | 450 | 900 | 36 | 50 |

Weclome your enquiry about silicon carbide ceramic foam filter at any time. We are willing to supplyyou superior filters in most competitive price with professional service.

- Q: What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- There may be a fault filtrate pump, diaphragm pump damage, pump mechanical seal failure, a leak, two is no output or output to the liquid, the pressure is too low, the cleaning effect is not good, the pressure is too large, will cause damage and reduce the concentration of slurry filter plate.

- Q: What is the backwashing pressure of the ceramic filter?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

- Q: Can the ceramic plate filter the hot air?

- The cleaning of the ceramic filter is divided into two parts: reverse flushing (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board. Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure. Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.). Other reasons such as 1,2,3 are normal, but can not be discharged from the spindle speed too fast, even the ceramic filter itself manufacturing defects, the user equipment modification and so on, are likely to lead to abnormal operation of equipment. We specialize in ceramic filter boards for many years and welcome exchanges.

Send your message to us

High Performance Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches