Ceramic Filter Plate 3 - Advanced Ceramic Filtration Solutions

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

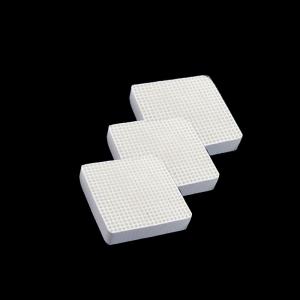

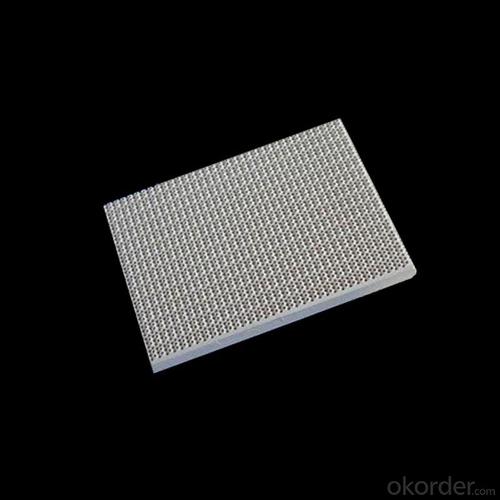

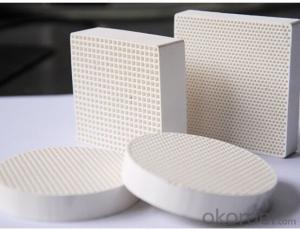

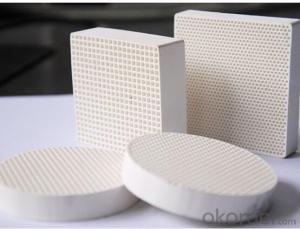

General Information of Ceramic Filter Plate

CMAX ceramic filter plate is made from high purity alumina silicate fibers mixing with inorganic binders by vacuum forming process. It is widely used in aluminum alloy melting furnace to control the production flow of molten aluminum. CMAX ceramic Filter Plate is a kind of large porous ceramic disc which is fired by inorganic membrane making technology. Regarding firing process, traditionally the ceramic plate is consisted of two layers of plates which are glued together to form inner channels. But after long term running, the glue will block the pores to cause flower spots on the surface of the plates.

Feature of Ceramic Filter Plate

Good thermal insulation

Durable mechanical strength

High strength, abrasion and corrosion resistantance and long service life.

Size of micropore is small (normally with diameter of 1.0um), strong capillary effect.

Low power and energy consumption as filter rates drawn into micropore automatically.

High filtration pressure drop (vacuum degree can reach-0.098Mpa) and low moisture of filter cake.

Application of Ceramic Filter Plate

Aluminum alloy melting furnace for die casting industry

Other shapes like sleeves or risers for sand casting foundry

Other shapes like sleeves or risers for sand casting foundry

the application can be divided into two types, one is used for the two phase separation, the other is to disperse a phase to another, that is to combine the two, especially for liquid filtration, gas filtration, fluidization, etc..

CNBM has success in its ceramic filter plate products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic filter plate application and would like to assist you in product selection, system design, and installation techniques. Our products of ceramic filter plateare in good quality and in best price.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The ceramic filter plate by table and the distribution of a large number of porous capillary ceramic filter, when working in the water slurry channel is used so the microporous ceramic filter plate internal residual has a lot of water, such as low temperature, the inside of the frozen water volume will swell, causing damage to the ceramic the inside of the microporous filter plate structure.

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- It is based on the action principle of capillary pore and realizes the solid-liquid separation through the capillary action principle of the micropore. Specifically, is the use of microporous ceramic plate water impermeable properties, extraction of ceramic plate and external cavity vacuum pressure, the suspended material groove under the action of the negative pressure adsorption on the ceramic plate, solid material through the porous ceramic plate can not be trapped in a ceramic plate surface, and the liquid due to the hydrophilic effect of vacuum pressure difference and ceramic plate by entering the gas-liquid distribution device, and then discharged or recycled, so as to achieve the purpose of solid-liquid separation.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The filtrate is not discharged smoothly.The filtrate can not be discharged in a timely and smooth manner, the new filtrate can not be sucked out, and the filtrate can not be continuously sucked out, so that the filter cake can not be adsorbed on the ceramic plate.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: What is the backwashing pressure of the ceramic filter?

- The working process of ceramic filter is: suction - drying - unloading - backwash - suction - drying - unloading - backwash...... In circulation, suction, the drying process is to make the slurry liquid by vacuum suction and capillary effect (usually water) through the filter media from the left, the filter cake on the filter medium (the two processes like syringe pumping), and then through the scraper discharge, after unloading, ceramic filter machine is complete a cycle in the absorption slurry, drying process, some fine particles may enter the filter medium or stacked on the surface (a lot of pipeline internal filtration medium ceramic filter plate), these small particles blockage will make the filter medium permeability and filtering effect of the loss from the poor, in order to reduce the possibility of blockage ceramic filter, will enter the backwash (this process is like a water jet injector). Ceramic filter backwash is through the pressure of water, these small particles plug discharge ceramic filter board.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the main shaft is rotated, the filter cake is adsorbed on the surface of the ceramic filter plate and dehydrated by the vacuum generated by the vacuum pump.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Ceramic Filter Plate 3 - Advanced Ceramic Filtration Solutions

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100Pcs pc

- Supply Capability:

- 2000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords