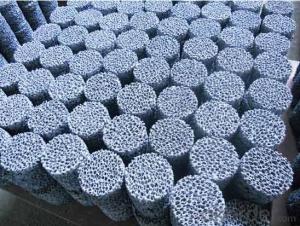

Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filter with Excellent Performance

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter for iron castings

Products confirm with China National Standard GB/T 25139-2010.

Application:For the filtration of molten Iron,copper ,aluminum and alloy.

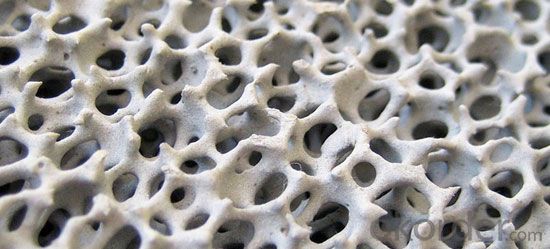

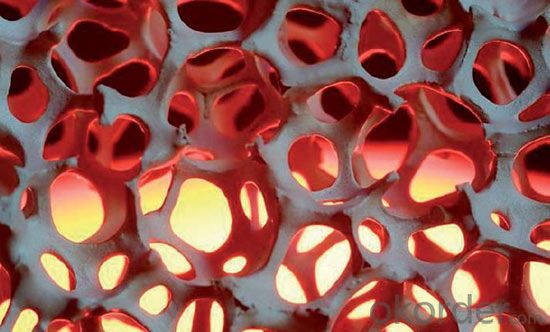

Silicon carbide ceramic foam filters are mainly designed to improve the quality of iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream.Additionally, they aid in reducing turbulence in the gating system.

SIC ceramic foam filter's outstanding thermal shock resistance and high strength properties were developed for superior performance in extreme iron or aluminum and copper based alloy foundry applications.

Product Features:

-Precise sizes control during filter media sponge cutting to final sinter.

-High strength with enough slurry and free from loose debris,no break and no filter slag

-Branded main raw material to ensure stable quality

-Good porosity and free from block during pouring molten metal

-Mature sintering technology to ensure high refractory and good thermal shock resistance.

Technique data:

Main material: Silicon Carbide

Max. applied temperature: ≤1500℃

Color:Gray black

Hole density (PPI):10/20/25/30(PPI=pores per inch)

Porosity(%): 80-90

High temperature bending strength(Mpa):≥2.5

Bending strength(Mpa):≥1.5

Compressive Strength(MPa) :≥1.0

Bulk Density(g/cm3): 0.43

Thermal shock resistance: 6 times/1100℃-room temp.

Dimensions:

Different sizes and PPI can be made upon customer request

Length*width*height=(35-200)*(35-200)*(10-30)mm

With round,square and rectangle shapes.Size tolerance:±1mm

Pore size: 10PPI/20PPI/25PPI/30PPI.PPI tolerance:± 2PPI

- Q: What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The incoming mud content, fine particle size, pulp itself is not suitable for the use of ceramic filter dehydration, if the use of ceramic filter dehydration in this case, will accelerate the blockage of ceramic filter plate, blocking the situation after the second reference description.

- Q: Why does not the iron filter of the ceramic filter work?

- You should make it clear that the filter cake has always been dry or suddenly dry, and now how much moisture? Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- Users such as pulp size is too small, too much mud, after analysis, the following methods of testing, the results have improved, it may wish to try the following methods, perhaps of help:The vacuum degree is about -0.08MPa.Adjust spindle speed and increase drying time.Ceramic filter plate with suitable pore size range.Ceramic filter plate brand on the market range, its quality is good or bad, the feed condition itself is not an ideal situation, such as ceramic filter plate with the aperture to the mine conditions do not match, it will exacerbate the effects of poor, life is short.It can shorten the combined cleaning cycle, strengthen the cleaning effect and prolong the cleaning time.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- The ceramic filter ceramic plate ceramic microporous pumping vacuum adsorption concentrate filtration water, the adsorption parameters according to the angle of rotation, reverse cleaning process, check whether there are loopholes in the exhaust pipe, check the ceramic plate use cycle is too long.

Send your message to us

Ceramic Filter Plate - Silicon Carbide Ceramic Foam Filter with Excellent Performance

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords