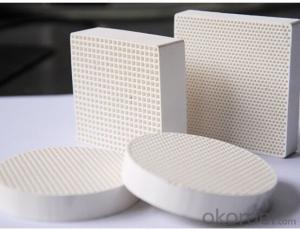

Ceramic Filter Plate for Foundry Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.High porosity, low loss of thermal shock, high mechanical strength.

2.Pore density PPI:10-40

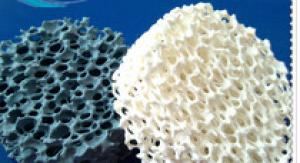

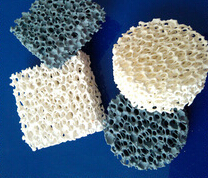

Ceramic Foam Filter

1. Introduction:

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

SIC Ceramic Foam filters are just developed as a new type molten metal filter to decrease casting flaw in recent years. With its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance,SIC Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, grey iron castings and malleable castings, Bronze casting, etc.

2. Size available:

7", 9", 12", 15", 17", 20", and 23", with porosities from PPI 10 to PPI 60(PPI ie pores per inch).

Other special sizes could be produced on request.

3. Material Specifications

4.1 SIC Physical Properties:

Porosity(%) | 80~90% |

Working Temperature | ≤1500°C |

Bending Strength(Mpa) | 0.8 |

Compression Strength(Mpa) | 0.9 |

Thermal Shock Resistance | 1100°C---room temperature 6 times |

Volume Density | 0.4-0.5g/cm3 |

4.2 Alumina Physical Properties:

Working | ≤1200°C |

Porosity | 80~90% |

Compression Strength | ≥1.0Mpa |

Volume Density | ≤0.5g/cm3 |

Thermal Shock Resistance | 800°C---Indoor temperature 5 times |

Application | non-ferrous and alumina alloys, |

5. Pouring Rate and Filtration Capacity

1) Alumina Ceramic Foam Filters

| Dimensions(mm) | Dimensions(inch) | Pouring Rate(kg/s) | Filtration Capacity(ton) |

| 178x178x50 | 7x7x2 | 0.2-0.6 | 5 |

| 228x228x50 | 9x9x2 | 0.3-1.0 | 10 |

| 305x305x50 | 12x12x2 | 0.8-2.5 | 15 |

| 381x381x50 | 15x15x2 | 2.2-4.5 | 25 |

| 430x430x50 | 17x17x2 | 3.0-5.5 | 35 |

| 508x508x50 | 20x20x2 | 4.0-6.5 | 45 |

| 585x585x50 | 23x23x2 | 5.0-8.6 | 60 |

2) Zirconia Ceramic Foam Filters

| Dimensions(mm) | Pouring Rate(kg/s) | Filtration Capacity(kg) |

| 50x50x22 | 3-5 | 30 |

| 50x75x22 | 4-6 | 40 |

| 75x75x22 | 7-12 | 60 |

| 75x100x22 | 8-15 | 80 |

| 100x100x22 | 14-20 | 100 |

D50x22 | 2-6 | 18 |

| D80x22 | 6-10 | 50 |

| D90x22 | 8-16 | 70 |

3) Silicon Carbide Ceramic Foam Filters

| Dimensions (mm) | Pouring Rate(kg/s) | Filtration Capacity(ton) | ||

| Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

| 40x40x22 | 4 | 3 | 65 | 32 |

| 50x50x22 | 6 | 4 | 100 | 52 |

| 75x50x22 | 9 | 6 | 150 | 75 |

| 75x75x22 | 14 | 9 | 220 | 100 |

| 100x50x22 | 12 | 8 | 200 | 100 |

| 100x75x22 | 18 | 12 | 300 | 150 |

| 100x100x22 | 25 | 16 | 400 | 200 |

| 150x150x22 | 50 | 36 | 900 | 450 |

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- At this time, take the filtrate (this is not the first water slurry) will pollute the ceramic filter pipe, friction ring, filtrate pump, may damage the vacuum system, remaining in the pipeline in the pulp will recoil pressure under the action of pollution caused by the other ceramic plates, ceramic plates blocked him. Once the ceramic plate is broken (depending on the severity), it will make the vacuum distortion, resulting in ceramic filter suction effect worse or even no suction!

- Q: Influence factors of ceramic filter

- On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed. Generally, the higher the temperature, the smaller the viscosity of the liquid, the more conducive to improve the filtration rate, reduce the cake or sediment water, while reducing the viscosity of the slurry, can improve the processing capacity.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: What is the working pressure of the ceramic filter?

- Generally speaking, there are two kinds of working pressure of ceramic filter: vacuum pressure and reverse flushing pressure.

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: Excuse me, what's the reason that all ceramic filters do not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

Send your message to us

Ceramic Filter Plate for Foundry Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords