Specifications

High tensile strength;

Stable quality

Cost-efficient price.

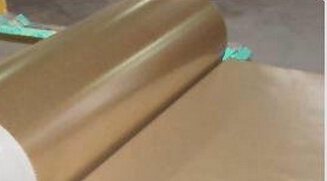

Mica Paper is the continuous reeled paper made from high quality muscovite, phlogopite and synthetic mica with mechanical pulp methods.

The production process: reduce the mica scrap to powder, make paper, cut to the demand size and roll paper to finished products.

Outstanding Character:

1. Excellent insulating property.

2. High Tensile Strength.

3. Good resin penetration and air permeability.

4. Homogeneous distribution of granularity and structure.

5. Widely used in make Mica Plate, Mica Tape and etc.

Specification:

Width: 960-1050mm

Thickness: 0.04-0.15mm

| Type | Weight g/m2 | Thickness mm | Penetration time s(≤) | Dielectric strength KV/mm(≥) | Tensile strength N/cm(≥) | Loss due to heating at 500°C %(≤) | Conductivity of aqueous extract µs/cm(≤) | Temp. Resistant °C(≥) |

| 506 | 80 | 0.055 | 10 | 18 | 3 | 0.4 | 9 | 600 |

| 160 | 0.1 | 30 | 18 | 3.6 | 0.4 | 9 | 600 | |

| 250 | 0.15 | 60 | 18 | 5.5 | 0.4 | 9 | 600 | |

| 350 | 0.22 | 105 | 18 | 7 | 0.4 | 9 | 600 | |

| 507 | 60 | 0.04 | 10 | 18 | 3 | 0.4 | 9 | 600 |

| 160 | 0.1 | 40 | 18 | 4 | 0.4 | 9 | 600 | |

| 250 | 0.15 | 70 | 18 | 5 | 0.4 | 9 | 600 | |

| 350 | 0.22 | 130 | 18 | 7 | 0.4 | 9 | 600 | |

| P506 | 90 | 0.6 | 16 | 18 | 3 | 0.4 | 10 | 800 |

| 160 | 0.1 | 35 | 18 | 4 | 0.4 | 10 | 800 | |

| 250 | 0.15 | 70 | 18 | 5 | 0.4 | 10 | 800 | |

| 350 | 0.22 | 130 | 18 | 7 | 0.4 | 10 | 800 | |

| S506 | 105 | 0.065 | 10 | 19 | 3 | 0.25 | 6 | 1000 |

| 120 | 0.07 | 14 | 19 | 3 | 0.25 | 6 | 1000 | |

| 160 | 0.1 | 20 | 19 | 3.5 | 0.25 | 6 | 1000 | |

| 501 | 90 | 0.6 | 16 | 20 | 3 | 0.4 | 10 | 1000 |

| 160 | 0.1 | 35 | 20 | 4 | 0.4 | 10 | 1000 | |

| 250 | 0.15 | 70 | 20 | 5 | 0.4 | 10 | 1000 | |

| 350 | 0.22 | 130 | 20 | 7 | 0.4 | 10 | 1000 |

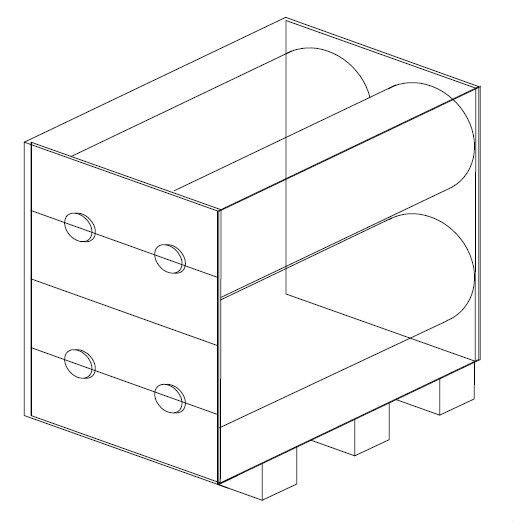

Packing: Wrapped up with PE film and fixed in wooden case.