Home Depot Short Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextiles made of virgin Polypropylene PP, Polyester PES

Under request, the geotextile is produced with black carbon to protect from UV

Features

1)Geotextile can make the water flow easily, and form a drainage channel in the soil, and then make the liquid and gas out of the soil.

Make use of its pulling resistance and deformation resistance that can strength the soil to reinforce the stability of the construction structure and improve the soil’s quality.

2) Make the focus proliferate, deliver and decompose efficiently and prevent the soil from destruction from outside factor.

3) Prevent the top and bottom layer’s gravel, soil and concrete from mixer.

4) The mesh cannot be plugged easily – for the strain and moving quality of the network that formed by the antitype fiber.

5) High soaking quality—at the pressure of soil, it also can keep good soaking quality.

6) Corrosion resistant – using the polypropylene and polyester as raw material, it can resist the sour and aid, erosion, boring and oxidation.

7) The construction is easy; the weight is light, convenient for using, and it making construction easy.

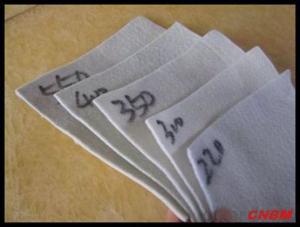

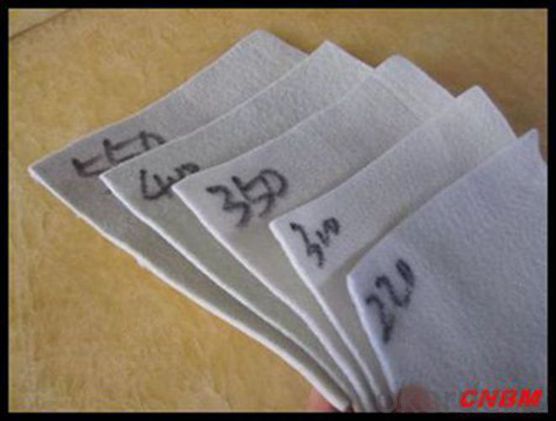

Non Woven Geotextile Product Show:

Non Woven Geotextile Product Show:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are designed to provide filtration, separation, and reinforcement in various civil engineering applications, including drainage systems. They can help prevent soil and fine particles from clogging the drainage pipes, while allowing water to pass through freely. Geotextiles also enhance the overall performance and longevity of the drainage system by reducing soil movement and erosion.

- Q: Application of composite geotextile

- Water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: GB / T-2008 has this standard on staple geotextile? What is the exact name? Know what to say thank you!

- Yuejian Group acupuncture non-woven geotextile. It has 1. Isolation 2. Filtration 3. Drain 4. Reinforcement 5. Protection 6. Closed effect. Wang Bin

- Q: How do geotextiles affect soil properties?

- Geotextiles can have a positive impact on soil properties by improving its stability, filtration, and drainage capabilities. These synthetic fabrics act as a barrier, preventing soil erosion and promoting soil compaction. Additionally, geotextiles can enhance the soil's ability to retain water, aiding in irrigation and reducing the risk of drought.

- Q: River slope protection geotextile unit area quality is generally how much

- Under normal circumstances is 100g - 1000g / square meter of the specifications, the actual situation is subject to special requirements, usually available geotextile unit area quality tester for testing, reference [standard group]. Test criteria: ASTM / D3776 / 2646, ISO3801, BS3424 / 2471, BSEN, M + SP65 / 65A, NEXT20

- Q: What are the factors to consider when selecting geotextiles for embankment stabilization?

- When selecting geotextiles for embankment stabilization, several factors should be considered. These include the strength and durability of the geotextile, its ability to withstand environmental conditions such as sunlight exposure and chemical degradation, its filtration and drainage properties, and its compatibility with the soil and other materials used in the embankment. Additionally, factors such as cost, installation requirements, and the specific project requirements and goals should also be taken into account.

- Q: Filtering geotextile calculation

- The amount of consultation and happy it

- Q: Measured geotextile vertical permeability, "highway engineering geosynthetics test procedures" T1141-2006 6.3 balanced head difference is not necessary to balance the 50mm? Can not balance ah more

- So deep, although we produce geotextile, but geotextile detection really is not proficient in it

- Q: Geotextile with glue can stick cement wall

- There is a professional ks glue, I was the manufacturer

- Q: 400 grams per square meter of non-woven geotextiles how much money

- According to your technical parameters, the specific number of professional geotextile manufacturers to answer, power to discuss!

Send your message to us

Home Depot Short Non-Woven Geotextile Fabric for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords