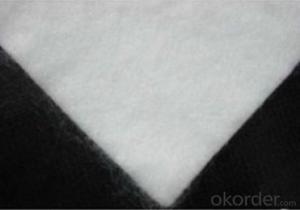

Short Fiber Nonwoven Geotextile For Road Project

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20FCL m.t.

- Supply Capability:

- 100 Million M2 Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Staple fibers needle punched nonwoven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament nonwoven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

Technical specification of short fiber Needle-punched Nonwoven geotextile:

Density |

Thickness | Breaking Strength | Elongation of Fracture | Tearing Strength | CBR Bursting Strength | Vertical Penetration Parameter | Equivalent Aperture |

g/m2 | mm | KN/m | % | KN | KN | cm/s | O95mm |

100 | 0.9 | 2.5 |

25 ~ 100 | 0.08 | 0.3 |

K x (10-1 ~ 10-3) (K = 1.0 ~ 9.9) |

0.07 ~ 0.2 |

150 | 1.3 | 4.5 | 0.12 | 0.6 | |||

200 | 1.7 | 6.5 | 0.16 | 0.9 | |||

250 | 2.1 | 8.0 | 0.20 | 1.2 | |||

300 | 2.4 | 9.5 | 0.24 | 1.5 | |||

350 | 2.7 | 11.0 | 0.28 | 1.8 | |||

400 | 3.0 | 12.5 | 0.33 | 2.1 | |||

450 | 3.3 | 14.0 | 0.38 | 2.4 | |||

500 | 3.6 | 16.0 | 0.42 | 2.7 | |||

600 | 4.1 | 19.0 | 0.46 | 3.2 | |||

800 | 5.0 | 25.0 | 0.60 | 4.0 |

Application of nonwoven geotextile:

Geotextile has excellent permeability, acquired, durability, which can be widely used in railway, highway, movement hall, Dams, hydraulic structures, hence hole, coastal shoal, reclamation, environmental protection and other projects. The main products are Synthetic staple fibers needle punched non woven geotextiles and slit and spilt film yarn woven geotextiles.

- Q: Do you need a cushion on the ground floor?

- In addition to wood also buy wooden side, used as the main beam, beam and pillars. The ground is also recommended to raise, raise the place also to beam and pillars The number of boards to be based on your design to determine the ground practice, roof practices will affect the number of wood

- Q: Foam concrete for the roof cushion generally do much bulk ah

- First help you correct it, foam concrete used in the roof should be the role of thermal insulation, not as a cushion.

- Q: Roof waterproof mattress should play the number of centimeters appropriate

- 4. The second layer to do mortar waterproof (mortar waterproof), waterproof at the same time can protect the bottom of the flexible waterproof.

- Q: Is it possible to make a waterproof layer

- 2, waterproof layer: In order to prevent the rain into the roof, groundwater into the wall, basement and underground structures, indoor water into the floor and walls and other materials layer.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board surface is best to do some cement mortar cushion, can prevent the decoration of the water generated to the downstairs.

- Q: What is the difference between leveling and cushion?

- Commonly used materials are, cement mortar leveling layer, fine stone concrete leveling layer, asphalt mortar leveling layer and so on. Leveling layer and the difference between the cushion, which is a very easy to confuse the two engineering concepts.

- Q: Cushion, waterproof layer construction to do what information

- 1, the cushion to do template inspection batch information. Waterproof to do waterproof shelter, waterproof inspection batch, waterproof detail structure.

- Q: What is the relationship between the cushion and the ring beam?

- There is no direct relationship between the cushion and the ring beam.

- Q: How to build a fine stone concrete cushion?

- Reduce ground cracking, plus steel mesh. Reinforced mesh, should be placed in the middle of the concrete, because the protective layer of concrete thick Fang generally only 5CM thickness, so the middle is the best.

- Q: Maintenance time of the cushion on the roof of the building

- According to the "concrete structure construction quality acceptance criteria" provides: Concrete should be poured within 12h after the completion of the concrete to be covered, and moisturizing conservation;

1. Manufacturer Overview

| Location | Shangdong, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | America; Europe; Asia |

| Company Certifications | ISO 9001; ISO 14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qindao; Yantai |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 40000square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

Short Fiber Nonwoven Geotextile For Road Project

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1*20FCL m.t.

- Supply Capability:

- 100 Million M2 Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords