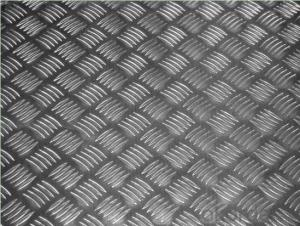

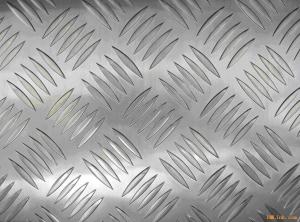

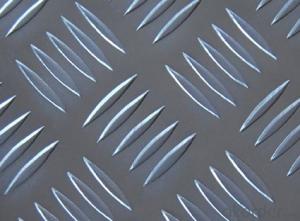

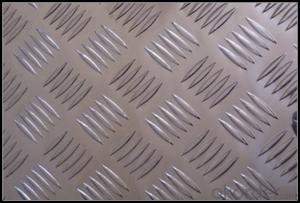

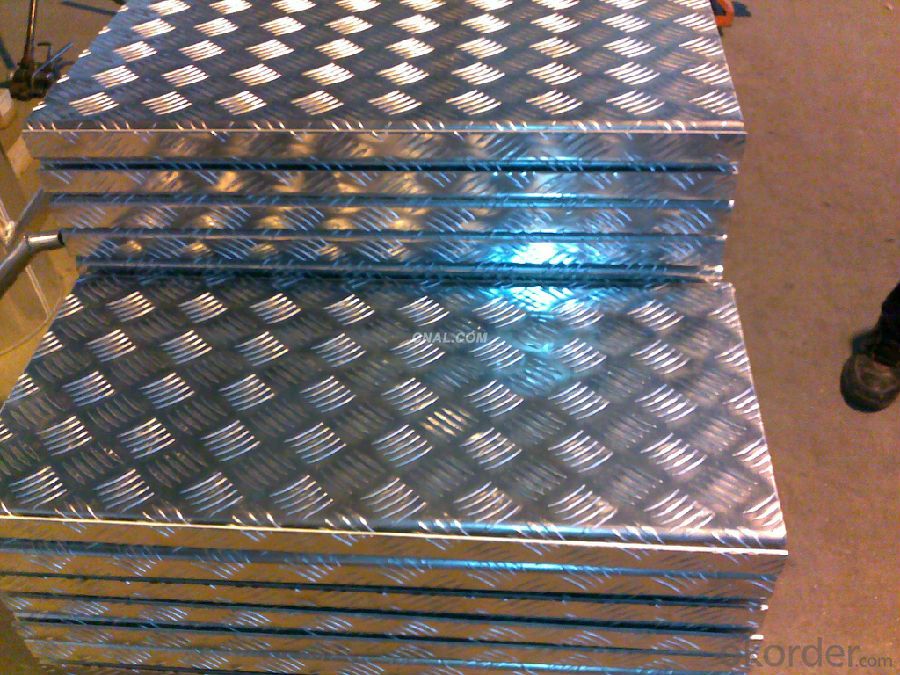

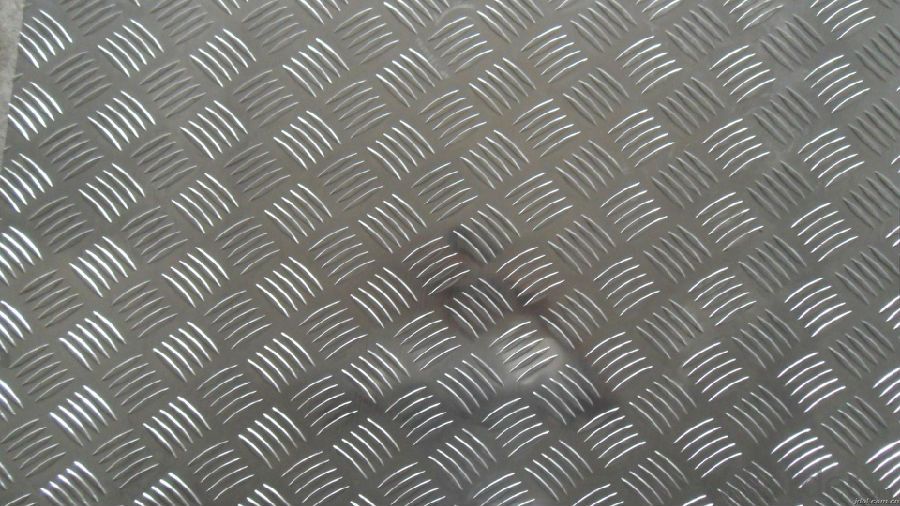

Sheets of Aluminum for Skid Resistance Application with Five Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium FIve Bars for Skid Resistance Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium FIve Bars for Skid Resistance Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium FIve Bars for Skid Resistance Application:

Aluminium FIve Bars for Skid Resistance Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium FIve Bars for Skid Resistance Application:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits associated with using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be recycled repeatedly without losing its quality or properties. This reduces the need for mining and extraction of new aluminum ore, which can contribute to deforestation, habitat destruction, and water and air pollution. Recycling aluminum sheets also requires significantly less energy compared to producing new ones, resulting in reduced greenhouse gas emissions and a smaller carbon footprint. Additionally, aluminum sheets are lightweight, which makes them a more sustainable alternative to other materials such as steel or plastic. The use of aluminum sheets in various industries, such as automotive and aerospace, can help reduce the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This is particularly important in the context of climate change and the need to reduce our dependence on fossil fuels. Furthermore, aluminum is corrosion-resistant, durable, and long-lasting, making it a sustainable choice for various applications. Its durability reduces the need for frequent replacements, thereby reducing waste generation. Moreover, aluminum sheets can be used in construction to improve insulation, leading to energy savings and reduced greenhouse gas emissions. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This makes it a safe material choice for various applications, including food packaging and medical equipment. In summary, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By choosing aluminum sheets over other materials, we can contribute to reducing resource extraction, energy consumption, greenhouse gas emissions, and waste generation, while promoting a more sustainable and environmentally friendly future.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- the forged iron crucible will honestly be dragging the warmth away,so attempt to discover a ceramic crucible---you will possibly have the potential to discover them at any rings furnish domicile.you will additionally so discover commercially arranged fluxes for melting,if no longer Borax powder is a fluxing agent I generally use.With the small quantity of meral you're wishing to soften,i think of your MAPP torch ought to artwork,be confident to change the flame to a lowering flame to steer clear of gassing the metallic.the availability domicile RIOGRANDE has an entire inventory of something you are able to require besides as some preprepared alloys which you will choose to objective.

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q: Are 101 aluminum sheets suitable for automotive applications?

- Indeed, automotive applications are well-suited for 101 aluminum sheets. This alloy, known for its high-strength composition, boasts impressive formability, corrosion resistance, and exceptional weldability. These attributes render it a favored selection for a range of automotive elements, including body panels, heat shields, and structural parts. Furthermore, the lightweight nature of 101 aluminum sheets aids in enhancing fuel efficiency and overall vehicle performance. In summary, the strength, formability, corrosion resistance, weldability, and lightweight characteristics of 101 aluminum sheets make them a highly suitable choice for automotive applications.

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is high, as aluminum has excellent ductility and can be easily shaped into various forms without cracking or breaking.

- Q: What industries use aluminum sheets?

- The industries that commonly use aluminum sheets include automotive, aerospace, construction, packaging, electrical, and manufacturing.

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets depends on the thickness and dimensions of each sheet. In general, the density of aluminum is about 2.7 grams per cubic centimeter (g/cm³). To calculate the density of 101 aluminum sheets, you would need to know the mass and volume of each sheet. By dividing the total mass of the sheets by their total volume, you can determine the density.

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- it particularly is authentic that many deodorants, quite those categorized anti-perspirants, incorporate aluminum chloride as an lively ingredient. Aluminum chloride does decrease sweat production via the sweat glands that are placed interior the floor and are quite ample under the hands. For some people who're heavy sweaters this drying consequence is amazingly significant. despite the fact that those deodorants decrease sweat production they do no longer block the sweat glands. we are no longer attentive to any at as quickly as risky outcomes on maximum persons from making use of a deodorant containing aluminum chloride. In our very close society at present, physique hygiene and prevention of physique smell are significant. in case you do no longer use a deodorant you are able to discover your persons the two complaining or keeping off you. while you're worried with reference to the drying consequence seem for a deodorant that would not incorporate aluminum chloride.

Send your message to us

Sheets of Aluminum for Skid Resistance Application with Five Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords