Schedule 40 Seamless Carbon Steel Pipe A335P91 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

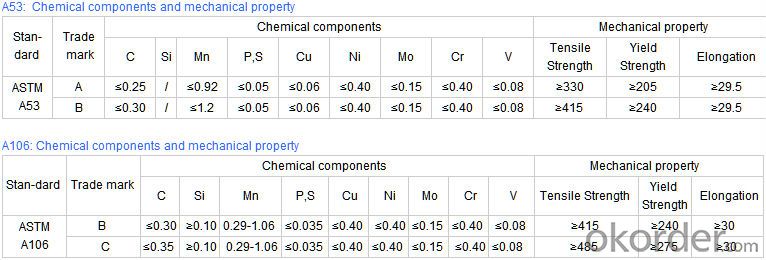

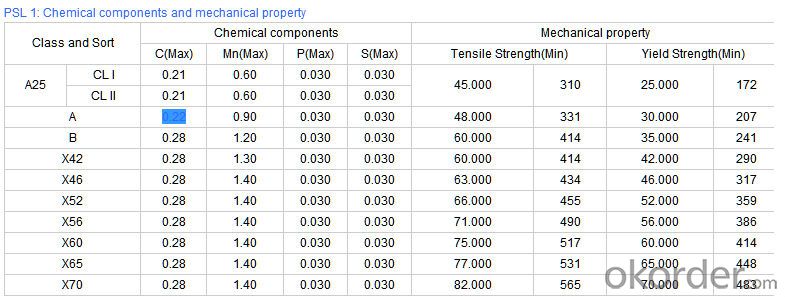

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: What is the difference between seamless steel pipes and seamless stainless steel pipes?

- The main difference between seamless steel pipes and seamless stainless steel pipes lies in their composition. Seamless steel pipes are made from carbon steel, which contains mainly iron and carbon. On the other hand, seamless stainless steel pipes are made from an alloy of iron, chromium, and other elements like nickel and molybdenum. The addition of these elements in stainless steel pipes provides enhanced corrosion resistance, making them suitable for applications where corrosion is a concern. Additionally, stainless steel pipes typically have a higher tensile strength and better heat resistance compared to regular steel pipes.

- Q: How are steel pipes cleaned and maintained?

- Steel pipes are cleaned and maintained through various methods. The process typically involves removing any debris or rust from the pipes using wire brushes or sandblasting. After cleaning, a protective coating is applied to prevent corrosion. Regular inspections and maintenance checks are also conducted to identify any potential issues such as leaks or weak points, ensuring the pipes remain in optimal condition.

- Q: How do you clean steel pipes?

- To effectively clean steel pipes, there are several steps that can be followed: 1. Collect the necessary supplies: You will require a pipe cleaning solution, either a scrub brush or wire brush, and safety gear like gloves and goggles. 2. Prepare the cleaning solution: Dilute the pipe cleaning solution according to the instructions provided on the packaging. Ensure that you select a solution suitable for steel pipes. 3. Prioritize safety: Put on your safety gear to safeguard yourself from any potential hazards. 4. Eliminate any debris: Before applying the cleaning solution, eliminate any loose debris or dirt from the surface of the steel pipes. You can utilize a brush or cloth to wipe away any visible particles. 5. Apply the cleaning solution: Immerse the brush into the prepared cleaning solution and administer it to the steel pipes. Ensure that you cover the entire surface, particularly focusing on areas with stubborn dirt or grime. 6. Scrub the pipes: Thoroughly scrub the steel pipes using the brush, applying pressure as needed to eliminate any buildup or stains. Pay extra attention to joints or hard-to-reach areas. 7. Rinse with water: Once you have completed the scrubbing, rinse the pipes with clean water to eliminate the cleaning solution and any remaining dirt. You can pour water over the pipes or employ a hose if available. 8. Dry the pipes: After rinsing, use a cloth or towel to completely dry the steel pipes. This will aid in preventing water stains or corrosion. 9. Inspect for cleanliness: Take a moment to inspect the pipes and ensure that they are clean. If there are still areas with stubborn dirt or stains, you may need to repeat the cleaning process or consider using a different cleaning solution. Always remember to adhere to the manufacturer's instructions when using cleaning solutions and to take appropriate safety measures.

- Q: How are steel pipes used in the manufacturing of furniture and appliances?

- Steel pipes are commonly used in the manufacturing of furniture and appliances for various purposes. They are used as structural components to provide stability and support, especially in items like chairs, tables, and bed frames. Steel pipes are also used as frames or frames within frames for cabinets, shelves, and storage units, offering durability and strength to hold heavy objects. Additionally, steel pipes can be used as handles or legs for appliances, ensuring stability and easy mobility. Overall, steel pipes play a crucial role in enhancing the strength, stability, and functionality of furniture and appliances in the manufacturing process.

- Q: What are the typical lengths of steel pipes?

- The typical lengths of steel pipes can vary depending on their purpose and application. However, common lengths range from 20 feet (6 meters) to 40 feet (12 meters) in commercial and industrial settings.

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes possess several distinct characteristics that set them apart from other pipe types. Primarily, their strength and durability are well-known. They exhibit remarkable resistance to heat, pressure, and corrosion, rendering them suitable for numerous applications. Additionally, their robustness allows them to bear heavy loads and offer an extended service life. One distinguishing feature of steel pipes lies in their versatility. They can be manufactured in various shapes and sizes to fulfill specific project requirements. This adaptability has contributed to their popularity across a diverse range of industries, including construction, oil and gas, water treatment, and manufacturing. Moreover, steel pipes exhibit exceptional thermal conductivity, facilitating efficient heat transfer between different areas. Consequently, they prove suitable for applications involving heating and cooling systems, as well as the transportation of hot fluids or gases. Furthermore, steel pipes are renowned for their resistance to fire. They possess a high melting point and are not easily ignited or conducive to the spread of flames. This characteristic is particularly critical in applications where fire safety is a concern, such as buildings or industrial facilities. Lastly, although steel pipes may entail a higher initial cost compared to other pipe types, their long-term benefits, such as durability and low maintenance requirements, often outweigh the initial investment. Additionally, steel pipes are highly recyclable, making them an environmentally friendly choice. In summary, steel pipes stand out due to their strength, durability, versatility, excellent thermal conductivity, fire resistance, and recyclability. These remarkable qualities establish steel pipes as the preferred option for a wide range of applications across various industries.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- 16Mn steel weldability is very good, general use TIG with J50 welding wire, hand arc welding with J506, J507 and other welding rod

- Q: What's the difference between a rectangular tube and a rectangular steel tube?

- No difference, but your name is different, rectangular steel pipe, but can be divided into seamless rectangular steel pipe and welded rectangular, these two, in the material will also have a difference, I do not know how to help you

- Q: What is the difference between steel pipes and ductile iron pipes?

- Steel pipes and ductile iron pipes are both commonly used for plumbing and industrial applications, but there are notable differences between them. The main difference lies in their composition and mechanical properties. Steel pipes are made primarily from iron and carbon, with small amounts of other elements added for strength and corrosion resistance. On the other hand, ductile iron pipes contain a higher percentage of carbon and small amounts of other elements like silicon and manganese, which give them improved ductility and resistance to cracking. Consequently, steel pipes are typically stronger and more rigid, suitable for high-pressure applications, while ductile iron pipes offer better flexibility and impact resistance, making them ideal for underground installations and areas prone to ground movement. Additionally, steel pipes are usually more expensive than ductile iron pipes due to their higher strength and corrosion resistance.

- Q: What are the different types of coatings used on steel pipes?

- There are several different types of coatings used on steel pipes, including polyethylene, fusion bonded epoxy, coal tar enamel, and asphalt enamel. These coatings provide protection against corrosion, abrasion, and other forms of damage, ensuring the longevity and durability of the steel pipes.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe A335P91 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords