SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

1)Application: It is widely applied to line pipe in oil and sewage transportation , and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

2)Standard: API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9700.1

3)Steel Grade: API SPEC 5L: B, X42, X46, X52, X56, X60, X65; API SPEC 5CT: J55, K55, N80, L80-1;ASTM A53: A, B, C; GB/T9700.1:L242、L290、L320、L360、L390、L415、L450

2. Sizes of SSAW Welded Steel Pipes API SPEC 5CT ASTM A53 ASTM A53

OD | WT | ||||||||

Noninal Pipe size Inches | MM | 10 | 20 | 30 | STD | 40 | 60 | XS | 80 |

12 | 323.90 |

| 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.70 | 17.48 |

14 | 355.60 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 |

16 | 406.40 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.70 | 21.44 |

18 | 457.00 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.88 |

20 | 508.00 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 |

22 | 559.00 | 6.35 | 9.53 | 12.7 | 9.53 |

| 22.23 | 12.70 | 28.58 |

24 | 610.00 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 |

26 | 660.00 | 7.92 | 12.70 |

| 9.53 |

|

| 12.70 |

|

28 | 711.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

30 | 762.00 | 7.92 | 12.70 | 15.88 | 9.53 |

|

| 12.70 |

|

32 | 813.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

34 | 864.00 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 |

| 12.70 |

|

36 | 914.00 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 |

| 12.70 |

|

38 | 965.00 |

|

|

| 9.53 |

|

| 12.70 |

|

40 | 1016.00 |

|

|

| 9.53 |

|

| 12.70 |

|

42 | 1067.00 |

|

|

| 9.53 |

|

| 12.70 |

|

44 | 1118.00 |

|

|

| 9.53 |

|

| 12.70 |

|

46 | 1168.00 |

|

|

| 9.53 |

|

| 12.70 |

|

48 | 1219.00 |

|

|

| 9.53 |

|

| 12.70 |

|

*Remarks: Besides referred sizes, we also can arrange production based on requirement of costumers.

3. Packing&Delivery

Packing Detail: Bundles with anti-rust painting and with plastic cap

Delivery Time: Within 20-30 days upon receving prepayment or L/C

4. Data Sheet

Standard: API SPEC 5L

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | ||

Yield strength | Tensile Strength | ||||

API SPEC 5L | PSL1 | ||||

B | ≥241 | ≥414 | |||

×42 | ≥290 | ≥414 | |||

×46 | ≥317 | ≥434 | |||

×52 | ≥359 | ≥455 | |||

×56 | ≥386 | ≥490 | |||

×60 | ≥414 | ≥517 | |||

×65 | ≥448 | ≥531 | |||

×70 | ≥483 | ≥565 | |||

PSL2 | |||||

Min | Max | Min | Max | ||

B | 241 | 448 | 441 | 758 | |

×42 | 290 | 496 | 414 | 758 | |

×46 | 317 | 524 | 434 | 758 | |

×52 | 359 | 531 | 455 | 758 | |

×56 | 386 | 544 | 490 | 758 | |

×60 | 414 | 565 |

517 |

758 | |

×65 |

448 |

600 |

531 |

758 | |

×70 |

483 |

621 |

565 | 758 | |

Chemical Composition(%)

Standard |

Grade | C | Mn | P | S | TI | CEV |

Max | Max | Max | Max | Max | Max | ||

API SPEC 5L | PSL1 | ||||||

B | 0.26 | 1.2 | 0.030 | 0.030 | 0.04 |

- | |

×42 | 0.26 | 1.3 | 0.030 | 0.030 | 0.04 | ||

×46,×52,×56,X60 | 0.26 | 1.4 | 0.030 | 0.030 | 0.04 | ||

X65 | 0.26 | 1.45 | 0.030 | 0.030 | 0.06 | ||

X70 | 0.26 | 1.65 | 0.030 | 0.030 | 0.06 | ||

PSL2 | |||||||

B | 0.22 | 1.20 | 0.025 | 0.015 | 0.04 |

0.43 | |

×42 | 0.22 | 1.30 | 0.025 | 0.015 | 0.04 | ||

×46,×52,×56, X60 | 0.22 | 1.40 | 0.025 | 0.015 | 0.04 | ||

X65 | 0.22 | 1.45 | 0.025 | 0.015 | 0.06 | ||

X70 | 0.22 | 1.65 | 0.025 | 0.015 | 0.06 | ||

Standard: GB/9711.1

Mechanical Properties

Standard | Grade | (MPa) | (MPa) | Min(%) |

Yield strength | Tensile Strength | Elongation | ||

GB/T9711.1 | L245 | ≥245 | ≥415 | 21 |

L290 | ≥290 | ≥415 | 21 | |

L320 | ≥320 | ≥435 | 20 | |

L360 | ≥360 | ≥460 | 19 | |

L390 | ≥390 | ≥490 | 18 | |

L415 | ≥415 | ≥520 | 17 | |

L450 | ≥450 | ≥535 | 17 | |

L485 | ≥485 | ≥570 | 17 |

Chemical Composition(%)

Standard | Grade | C | Mn | P | S |

Max | Max | Max | Max | ||

GB/T9711.1 | L245 | 0.26 | 0.15 | 0.030 | 0.030 |

L290 | 0.28 | 1.25 | 0.030 | 0.030 | |

L320, L360 | 0.30 | 1.25 | 0.030 | 0.030 | |

L390, L415 | 0.26 | 1.35 | 0.030 | 0.030 | |

L450 | 0.26 | 1.40 | 0.030 | 0.030 | |

L485 | 0.23 | 1.60 | 0.025 | 0.030 |

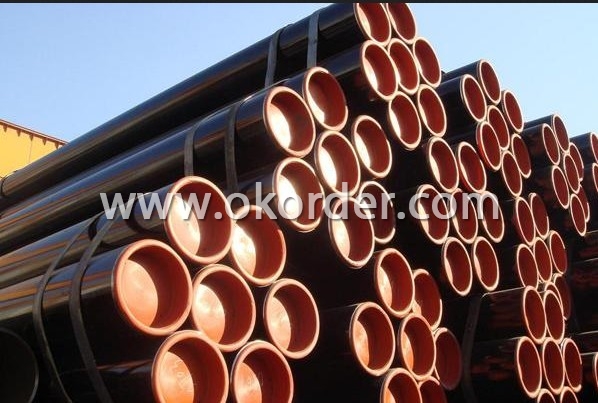

5. Products Showroom

- Q: How are steel pipes used in the construction of railways?

- Steel pipes are commonly used in the construction of railways for various purposes. They are primarily used in the fabrication of track structures, such as track supports, bridge components, and culverts. Steel pipes provide strength, durability, and resistance to external factors like corrosion and extreme weather conditions. They are also used for the transportation of fluids, such as water or fuel, within the railway infrastructure, ensuring efficient operation and maintenance of the system.

- Q: What are the different methods of protecting steel pipes from external damage?

- There are several methods of protecting steel pipes from external damage, including coating the pipes with a corrosion-resistant material such as epoxy or polyethylene, applying a layer of protective tape, installing a cathodic protection system, using concrete or rock shielding, and implementing measures to prevent soil movement or impact damage.

- Q: What does "spiral welded steel pipe" DN325*10 mean?

- Labeling is wrong: it should be said for 325*10, the diameter of pipe wall thickness of 10, 325;For example, the nominal diameter shall be: DN300.

- Q: Can steel pipes be used for underground sprinkler systems?

- Indeed, underground sprinkler systems can utilize steel pipes. Renowned for their durability and strength, steel pipes prove to be a fitting choice for underground applications. Their resistance to corrosion and ability to withstand high pressure and temperature render them suitable for conveying water to sprinkler heads. Nonetheless, it is crucial to acknowledge that steel pipes may necessitate supplementary coatings or protective measures to prevent rusting and corrosion in the long run. Moreover, the cost factor should be taken into account as steel pipes may be pricier compared to alternative materials like PVC or polyethylene. All in all, steel pipes can serve as a feasible option for underground sprinkler systems, particularly in regions with more severe environmental conditions.

- Q: How do steel pipes handle pressure surges?

- Steel pipes are known for their strength and durability, which allows them to handle pressure surges effectively. When pressure surges occur in a pipeline system, steel pipes have the ability to withstand and absorb the increased force without breaking or rupturing. The high tensile strength of steel provides resistance against the pressure exerted on the pipes, preventing them from deforming or collapsing under the sudden surge. Additionally, steel pipes have a high burst pressure rating, meaning they can withstand significant increases in pressure without failing. Furthermore, steel pipes are often designed with a thicker wall thickness, which adds to their ability to handle pressure surges. The thickness of the pipe walls helps to distribute the increased force evenly, minimizing the risk of localized stress and potential failure points. Moreover, steel pipes are commonly used in conjunction with fittings and valves that are specifically designed to handle pressure surges. These fittings and valves are made from similar materials, ensuring compatibility and maintaining the integrity of the pipeline system. Overall, steel pipes are well-suited for handling pressure surges due to their strength, durability, and ability to withstand high pressures. Their resistance to deformation, high burst pressure rating, and compatibility with specialized fittings and valves make them a reliable choice for applications where pressure surges may occur.

- Q: Are steel pipes suitable for high-temperature applications?

- Yes, steel pipes are suitable for high-temperature applications. Steel has excellent thermal conductivity and can withstand high temperatures without losing its structural integrity. Additionally, steel pipes have high tensile strength and can resist thermal expansion and contraction, making them ideal for transporting hot liquids or gases in industrial processes.

- Q: What is the difference between hot-dipped galvanized and electro-galvanized steel pipes?

- Hot-dipped galvanized steel pipes are coated with a thick layer of zinc by immersing them in a bath of molten zinc, creating a durable and corrosion-resistant coating. On the other hand, electro-galvanized steel pipes are coated with a thinner layer of zinc through an electroplating process, offering a more economical and aesthetically pleasing option.

- Q: Can steel pipes be used for industrial ventilation systems?

- Yes, steel pipes can be used for industrial ventilation systems. They are commonly used due to their durability, resistance to corrosion, and ability to withstand high temperatures. Steel pipes are also strong and can handle the pressure required for efficient airflow in industrial environments.

- Q: Can steel pipes be used for oil transportation?

- Yes, steel pipes can be used for oil transportation. Steel pipes are commonly used in the oil and gas industry for the transportation of crude oil, petroleum products, and natural gas. They are preferred due to their strength, durability, and resistance to corrosion. Steel pipes are capable of withstanding high-pressure environments and can be used for both onshore and offshore oil transportation. Additionally, steel pipes can be welded together to form long pipelines, making them a cost-effective solution for transporting oil over long distances. Overall, steel pipes are a reliable and efficient choice for oil transportation.

- Q: Can steel pipes be used for air conditioning systems?

- Yes, steel pipes can be used for air conditioning systems. Steel pipes are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems as they are durable, can withstand high pressures, and are resistant to corrosion.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2001 |

| Annual Output Value | 500,000Tons |

| Main Markets | Southeast Asia; Middle East; Oceania; Americas; Europe; Africa;etc. |

| Company Certifications | API 5L;API 5CT;ISO9001:2008 GB/T 19001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

SSAW Welded Steel Pipes API SEPC 5L API SPEC 5CT ASTM A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords