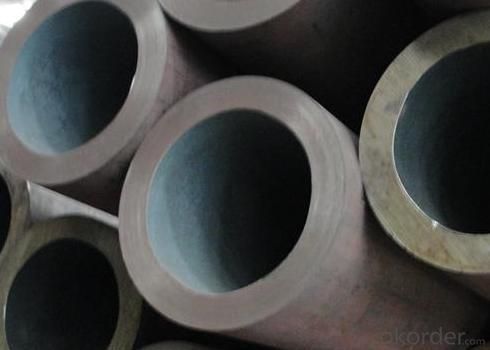

High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

1) Superior in quality

2) Quick in delivery

3) OD: 8-720mm WT:3-60mm

4) Material: 10# 20#,304 Q235 Q235B

Size OD: 3-60mm

WT: 8-720MM

Standard: GB/T8162 GB3087 BGZJ518-2006 GB/T8163

Grade : 20#,304 Q235 Q235B Q235C Q235D and so on

End : BE and Plain end with pipe caps

Technique :Cold rolled, hot rolled, cold drawn

Usage: Used for industrial pipe, high-pressure boiler pipe, and food industry

Payment: TT and irrevocable L/C

Packaging of High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments:

Wrapped in bundles with steel strips or according to customers' requirements

- Q: Can steel pipes be used for conveying chemicals?

- Yes, steel pipes can be used for conveying chemicals. Steel is a strong and durable material that can withstand high pressure and temperature conditions, making it suitable for transporting various chemicals. Additionally, steel pipes have excellent resistance to corrosion, which is crucial when dealing with corrosive substances. They are commonly used in industries such as oil and gas, chemical processing, and water treatment where the safe and efficient transport of chemicals is essential. However, it is important to consider the specific requirements of the chemical being conveyed and ensure that the steel pipe is compatible with it. Proper material selection, including the use of corrosion-resistant coatings or linings, may be necessary to prevent any adverse reactions between the chemicals and the steel pipe.

- Q: How are steel pipes used in the manufacturing of boilers and heat exchangers?

- Boilers and heat exchangers rely on steel pipes as an essential component due to their exceptional properties and capabilities. These pipes are specifically designed to endure high temperatures, pressures, and corrosive environments, making them highly suitable for these purposes. When constructing boilers, steel pipes are employed to form the main body or shell. This shell contains the water or steam that is heated to generate heat or produce steam for diverse industrial processes. The steel pipes used in boilers are typically seamless or welded, possessing precise dimensions and exceptional strength to ensure structural integrity and prevent any potential leaks. Heat exchangers, on the other hand, are devices used for transferring heat between two fluids, often with varying temperatures. Steel pipes are utilized in heat exchangers as the primary medium for heat transfer. The pipes are commonly arranged in a pattern, allowing the hot fluid to pass through one set of pipes while the cold fluid passes through another set. This arrangement facilitates efficient heat transfer between the two fluids. The use of steel pipes in boilers and heat exchangers provides numerous advantages. Firstly, steel pipes exhibit excellent thermal conductivity, enabling efficient heat transfer between the fluid and the surrounding environment. Secondly, steel pipes possess high tensile strength and can withstand high pressures, ensuring the safety and reliability of the equipment. Thirdly, steel pipes are highly resistant to corrosion, which is crucial in environments where the processed fluids are corrosive or contain impurities. Furthermore, steel pipes can be easily fabricated and customized to meet the specific requirements of boilers and heat exchangers. They can be manufactured in various sizes, lengths, and thicknesses to accommodate diverse applications. Additionally, steel pipes can be coated or lined with materials such as ceramic or epoxy to provide additional protection against corrosion or abrasion. In conclusion, steel pipes play a crucial role in the manufacturing of boilers and heat exchangers. Their exceptional properties, including high strength, thermal conductivity, and corrosion resistance, make them the optimal choice for these applications. The use of steel pipes ensures the efficient operation, safety, and longevity of boilers and heat exchangers in various industrial processes.

- Q: How to distinguish between steel pipe and spiral pipe material?

- Steel pipe according to the pipe material (ie steel) can be divided into: carbon tube and alloy tube, stainless steel tube.Carbon tube can be divided into ordinary carbon steel tube and high quality carbon structure tube.

- Q: What are the common methods for joining steel pipes?

- Different methods exist for joining steel pipes, depending on specific applications and requirements. Some commonly employed techniques include the following: 1. Welding: Among the most frequently used methods to join steel pipes, welding involves heating the pipe ends and applying pressure to fuse them. Various techniques can be employed, such as arc welding, MIG welding, TIG welding, and even laser welding. 2. Threaded connections: This method involves threading the ends of steel pipes to create male and female connections. These threaded ends are then screwed together using pipe threads. Threaded connections are typically utilized for smaller diameter pipes and in low-pressure applications. 3. Flanged connections: Flanges are employed to join steel pipes in situations that necessitate easy assembly and disassembly or frequent maintenance. Flanges are flat, circular discs with bolt holes that allow for the bolting of pipes together. They offer a robust and leak-proof connection. 4. Compression fittings: Compression fittings enable the joining of steel pipes without the need for welding or threading. They consist of a compression nut, compression ring, and compression sleeve. The nut is tightened onto the sleeve, compressing it against the pipe and creating a secure connection. 5. Grooved couplings: Mechanical connections are created with grooved couplings, which are utilized to join steel pipes. The pipe ends are grooved, and a gasket is inserted between the grooves. The couplings are then tightened, compressing the gasket and forming a tight seal. 6. Soldering or brazing: These methods involve the use of filler metal with a lower melting point than the steel pipes. The filler metal is heated and melted, allowing it to flow between the pipe joints and create a bond. Soldering is generally suited for smaller diameter pipes and low-pressure applications. Each joining method has its own advantages and limitations. The appropriate method for joining steel pipes depends on factors such as pipe diameter, application, working pressure, and required joint durability. It is crucial to consider these factors and consult industry standards and guidelines when selecting the suitable joining method for steel pipes.

- Q: What is the outer diameter of the steel tube?

- The outer diameter refers to the maximum diameter including the thickness of the steel tube, the inner diameter is the length of the hollow part inside, and the outer diameter minus the inside diameter is the thickness of the steel pipe

- Q: What is the purpose of galvanizing steel pipes?

- The purpose of galvanizing steel pipes is to provide corrosion resistance and extend their lifespan.

- Q: What is the role of steel pipes in the renewable energy sector?

- Steel pipes play a crucial role in the renewable energy sector by facilitating the transportation and distribution of various energy sources. One significant application of steel pipes is in the construction of pipelines for transporting natural gas, which is increasingly being used as a cleaner alternative to traditional fossil fuels. These pipelines are often made of steel due to its strength, durability, and resistance to corrosion, ensuring the safe and efficient delivery of natural gas to power plants and other energy consumers. Moreover, steel pipes are utilized in the installation of geothermal energy systems. Geothermal energy harnesses the heat from the earth's core to generate electricity or provide heating and cooling. Steel pipes are used to create geothermal wells, allowing for the extraction of hot water or steam from underground reservoirs. These pipes must withstand high temperatures and pressures, making steel an ideal material for this application. Additionally, steel pipes are employed in the construction of hydraulic systems for hydroelectric power plants. These plants rely on the force of flowing water to generate electricity, and steel pipes are used to convey water from the reservoir to the turbines. The durability and reliability of steel ensure the efficient transmission of water, enabling hydroelectric power plants to produce clean and renewable energy. In the renewable energy sector, steel pipes also play a role in the construction of solar power plants. Solar thermal systems use mirrors or lenses to concentrate sunlight and generate heat, which is then transferred to a fluid to produce steam and drive turbines. Steel pipes are essential for circulating and transferring this fluid, ensuring the effective operation of the solar power plant. In summary, steel pipes are indispensable in the renewable energy sector for their strength, durability, and resistance to corrosion. They enable the transportation of natural gas, the extraction of geothermal energy, the transmission of water in hydroelectric power plants, and the circulation of fluids in solar power plants. By facilitating the efficient distribution of various energy sources, steel pipes significantly contribute to the growth and sustainability of the renewable energy sector.

- Q: What are the different wall thicknesses available for steel pipes?

- There are various wall thicknesses available for steel pipes, depending on the specific requirements and applications. Steel pipes come in different schedules, which indicate the wall thickness. The most common wall thicknesses for steel pipes are Schedule 40, Schedule 80, and Schedule 160. Schedule 40 steel pipes have a relatively medium wall thickness and are commonly used for general-purpose applications, such as conveying fluids and gases. They are suitable for low-pressure systems and are widely used in plumbing, HVAC, and irrigation systems. Schedule 80 steel pipes have a thicker wall compared to Schedule 40 pipes and are designed for high-pressure applications. They are commonly used in industrial settings, oil and gas pipelines, and high-pressure fluid transport systems. The increased wall thickness provides higher strength and durability to withstand the pressure. Schedule 160 steel pipes have the thickest wall among the commonly available options. They are designed for extremely high-pressure applications, such as in refineries, chemical plants, and power generation facilities. These pipes provide exceptional strength and can handle the intense pressure and stress found in these industrial environments. Apart from these standard schedules, there are also other wall thicknesses available for specific purposes. For example, extra-strong (XS) pipes have a thicker wall than Schedule 80 pipes and are used for applications that require even higher pressure resistance. It is important to consult with professionals or refer to industry standards to determine the appropriate wall thickness for a specific application. Factors such as fluid or gas pressure, temperature, and environmental conditions should be considered when selecting the appropriate steel pipe with the desired wall thickness.

- Q: Are steel pipes suitable for underground irrigation systems?

- Underground irrigation systems can indeed benefit from the use of steel pipes. Renowned for their durability and strength, steel pipes exhibit resistance to corrosion and can withstand significant pressure. Furthermore, they are less prone to cracking or breaking when subjected to the weight and pressure of the ground. Moreover, steel pipes boast an extended lifespan, alleviating the need for frequent replacements. Nevertheless, it is crucial to consider the composition of the water being conveyed, as certain minerals or chemicals may induce corrosion over time. In such instances, it might be necessary to employ corrosion-resistant coatings or liners. All in all, steel pipes represent a dependable choice for underground irrigation systems, particularly in regions characterized by elevated water pressure or when durability takes precedence.

- Q: Are steel pipes suitable for transporting chemicals?

- Yes, steel pipes are suitable for transporting chemicals. They are known for their durability, corrosion resistance, and high strength, which makes them ideal for carrying various chemicals safely and efficiently. Additionally, steel pipes can withstand high pressure and extreme temperatures, making them a reliable choice for transporting chemicals in industries such as oil and gas, petrochemicals, and manufacturing.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2001 |

| Annual Output Value | 800,000Tons |

| Main Markets | Europe and the United States; Canada; India; South etc. |

| Company Certifications | API 5L; API 5CT; GB/T19001-2000 idt ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Lianyungang |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 423,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Seamless Steel Tubes For High-pressure For Chemical Fertilizer Equipments

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords