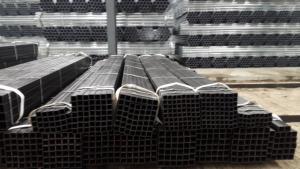

Square tube and rectangular tube for building structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Square tube and rectangular tube for building structure :

Square tube, square tube is a kind of call and rectangular tube, is equal and not equal to the length of steel pipe. Is the strip through the process of processing roll system. In general is the strip through the demolition of the package, flat, curly, welded to form a circular tube, and then rolled into a square tube and then cut into a square tube and then cut into the required length.

2、Main Features of Square tube and rectangular tube for building structure :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、 Square tube and rectangular tube for building structure Specification:

Standard | GB, DIN, ASTM |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1.5 - 25 mm |

Section Shape | Square and rectangular |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Place of Origin | Tianjin, China (Mainland) |

Length | 3-12M |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Grade | 235B 345B |

Standard | ASME, ASTM |

1) Material:(ASTM A 106/A53 GRB.API5LGRB,GB,235B,345B

2) Specification range:OD: 20*30mm----300*500mm 20*20 mm---400*400mm ,WT: 1.5 - 25 mm ,length:3-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut ,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Square tube and rectangular tube for building structure :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53 Images:

- Q: Are steel tubes and round steel in weight or length when purchased?

- It's priced by weight. The cutting process should size to determine the length (otherwise - please specify the weight of the material), the material ration to calculate weight for cost accounting as.

- Q: How much is 4 inches steel tube MM?

- 1 inches =25.4 mm;4 inches =101.6 mm;The specification of steel pipe is usually nominal size;

- Q: Can steel pipes be used for solar power systems?

- Yes, steel pipes can be used for solar power systems. Steel pipes are commonly used for various applications in solar power systems, including the construction of support structures, mounting systems, and piping systems for circulating heat transfer fluids. Steel pipes are preferred due to their strength, durability, and resistance to environmental conditions. They can handle the weight of solar panels, support structures, and withstand the forces exerted by wind and other external factors. Additionally, steel pipes can be easily customized and welded to meet specific project requirements. Overall, steel pipes are a reliable and cost-effective choice for solar power systems.

- Q: How are steel pipes used in the manufacturing of railways?

- Steel pipes are used in various ways in the manufacturing of railways. One of the primary uses of steel pipes in this context is for the construction of the railway track itself. Steel pipes are used to create the rail tracks that form the foundation of the railways. These pipes are typically welded together to form long, sturdy tracks that can withstand the weight and pressure of trains passing over them. Steel pipes are also used in the manufacturing of railway bridges and tunnels. These structures require strong and durable materials to ensure the safety and stability of the railway system. Steel pipes are often used in the construction of the support structures or piers that hold up the bridges. They are also used in the creation of tunnels, providing structural support and stability. Additionally, steel pipes are used in the manufacturing of various railway components and equipment. For example, steel pipes are used in the fabrication of railway signaling systems, which are responsible for controlling the movement of trains and ensuring safety. These pipes are often used to house and protect the electrical wiring and other components of the signaling systems. Furthermore, steel pipes are used in the manufacturing of railway carriages and locomotives. These pipes are used to create the framework and structure of the train, providing strength and stability. They are also used for various other purposes, such as the creation of air conditioning systems, brake systems, and fuel delivery systems within the train. Overall, steel pipes play a crucial role in the manufacturing of railways. They are used for the construction of rail tracks, bridges, tunnels, and various railway components and equipment. The strength and durability of steel make it an ideal material for ensuring the safety and efficiency of railway systems.

- Q: Can steel pipes be used for food processing facilities?

- Steel pipes are indeed applicable for food processing facilities. These pipes are frequently utilized in such facilities because of their impressive robustness, strength, and ability to resist corrosion. Moreover, they can be easily cleaned, a crucial factor in maintaining the required hygiene standards in food processing environments. Furthermore, steel pipes are capable of withstanding high temperatures and pressure, rendering them suitable for a wide range of food processing applications, including the transportation of liquids, gases, and solids. Nevertheless, it is imperative to guarantee that the steel pipes employed in food processing facilities are constructed from materials that have received approval for food contact. Additionally, regular inspections and maintenance must be carried out to prevent any potential risks of contamination.

- Q: Can steel pipes be used for underground sewer lines?

- Yes, steel pipes can be used for underground sewer lines. Steel pipes are commonly used in sewer systems due to their strength, durability, and resistance to corrosion. They are able to withstand the weight of soil and other external pressures, making them suitable for underground applications. Additionally, steel pipes have a long lifespan and can effectively transport wastewater and sewage for many years. However, it is important to ensure that the steel pipes are properly coated or lined to prevent corrosion and extend their lifespan even further.

- Q: What are the different international standards for steel pipes?

- There are several international standards for steel pipes that are widely recognized and used in the industry. Some of the key standards include: 1. ASTM A53: This standard covers seamless and welded black and hot-dipped galvanized steel pipes. It is commonly used for low-pressure applications such as water, gas, and steam. 2. ASTM A106: This standard covers seamless carbon steel pipes for high-temperature service. It is widely used in refineries, power plants, and petrochemical industries where high pressure and temperature conditions exist. 3. ASTM A312: This standard covers seamless, welded, and heavily cold worked austenitic stainless steel pipes. It is often used for high-temperature and corrosive environments in industries such as chemical processing, food processing, and pharmaceuticals. 4. API 5L: This standard specifies requirements for the manufacture of two product specification levels (PSL1 and PSL2) of seamless and welded steel pipes for use in pipeline transportation systems in the petroleum and natural gas industries. 5. EN 10216: This European standard covers seamless steel pipes for pressure purposes. It is used in various industries such as power generation, chemical, and oil and gas. 6. JIS G3454: This Japanese standard covers carbon steel pipes for pressure service. It is commonly used in the transportation of water, gas, and oil. 7. DIN 2448: This German standard specifies seamless steel pipes for general purposes. It is widely used in various industrial applications. These are just a few examples of the many international standards that exist for steel pipes. Each standard specifies different requirements for manufacturing, dimensions, mechanical properties, and testing to ensure the quality and performance of the pipes in specific applications. It is important for manufacturers, suppliers, and users to understand and comply with the relevant standards to ensure the safe and reliable use of steel pipes.

- Q: Are steel pipes suitable for high-pressure applications?

- Yes, steel pipes are suitable for high-pressure applications. Steel pipes are known for their strength and durability, making them ideal for handling high-pressure applications. They can withstand the internal pressure exerted by fluids or gases under high pressure without deforming or bursting. The high tensile strength of steel allows it to resist the forces that occur in high-pressure environments, ensuring the safety and reliability of the piping system. Additionally, steel pipes can be manufactured with thicker walls to further enhance their ability to withstand high pressures. Steel pipes are widely used in industries such as oil and gas, petrochemical, power generation, and water distribution, where high-pressure applications are common.

- Q: What is the difference between seamless and welded steel pipes?

- The main difference between seamless and welded steel pipes lies in their manufacturing process. Seamless steel pipes are made by piercing a solid billet to form a hollow tube, while welded steel pipes are formed by rolling a flat sheet of steel into a tube and then welding the seam. This difference in manufacturing leads to varying characteristics such as strength, appearance, and cost. Seamless pipes are generally considered to have higher strength and are more aesthetically pleasing, but they are also more expensive to produce. Welded pipes, on the other hand, are more cost-effective and suitable for less demanding applications.

- Q: What is a tight steel tube?

- JDG pipe is the replacement of traditional PVC and SC pipes and other traditional wire conduits. It is a breakthrough in the field of building electrical field using new materials and technologies. The JDG pipe adopts the cross connecting ground wire of galvanized steel pipe and thin-wall steel pipe, overcomes the defects of complicated construction and large construction loss of common metal pipe, and solves the problems of poor fire resistance and difficult grounding of PVC pipe. Because the JDG pipe material is more expensive than the ordinary pipe material, it is more used in the construction, such as comprehensive wiring, fire protection wiring and so on.

Send your message to us

Square tube and rectangular tube for building structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords