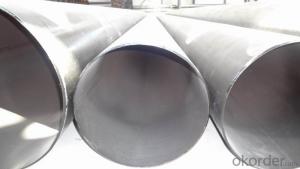

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t. m.t.

- Supply Capability:

- Based On Order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

Products Type Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

API 5L LSAW Welded Steel Pipes

Longitudinal Submerged Arc Welded (LSAW) Steel Pipe

API 5L SSAW Welded Steel Pipes

Spiral Submerged Arc Welded (SSAW) Steel Pipe

API 5L ERW Welded Steel Pipes

Electric Resistance Arc Welded (ERW) Steel Pipe

Specifications of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

Standard: API 5L, IPS, GB, BS, ASTM, JIS, ISO

Main Steel Tube Grade: A.B.X42,X46,X52,X56,X60,X70,L242、L290、L320、L360、L390、L415、L450(etc)

Dimensions:

OD: 406.4MM-1422MM (16"-56")

Thickness: 8MM-50.8MM depends on OD

Length: 5.8M-12M

Mechanical Properties Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

|

Standard |

Grade |

(MPa) |

(MPa) | |||

|

Yield strength |

Tensile Strength | |||||

|

API SPEC 5L |

PSL1 | |||||

|

B |

≥241 |

≥414 | ||||

|

×42 |

≥290 |

≥414 | ||||

|

×46 |

≥317 |

≥434 | ||||

|

×52 |

≥359 |

≥455 | ||||

|

×56 |

≥386 |

≥490 | ||||

|

×60 |

≥414 |

≥517 | ||||

|

×65 |

≥448 |

≥531 | ||||

|

×70 |

≥483 |

≥565 | ||||

|

PSL2 | ||||||

|

|

Min |

Max |

Min |

Max | ||

|

B |

241 |

448 |

441 |

758 | ||

|

×42 |

290 |

496 |

414 |

758 | ||

|

×46 |

317 |

524 |

434 |

758 | ||

|

×52 |

359 |

531 |

455 |

758 | ||

|

×56 |

386 |

544 |

490 |

758 | ||

|

×60 |

414 |

565 |

517 |

758 | ||

|

×65 |

448 |

600 |

531 |

758 | ||

|

×70 |

483 |

621 |

565 |

758 | ||

Chemical Composition Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries: (%)

|

Standard |

Grade |

C |

Mn |

P |

S |

CEV |

|

Max |

Max |

Max |

Max |

Max | ||

|

PSL1 |

- | |||||

|

B |

0.26 |

1.2 |

0.030 |

0.030 | ||

|

×42 |

0.26 |

1.3 |

0.030 |

0.030 | ||

|

×46,×52,×56,X60 |

0.26 |

1.4 |

0.030 |

0.030 | ||

|

X65 |

0.26 |

1.45 |

0.030 |

0.030 | ||

|

X70 |

0.26 |

1.65 |

0.030 |

0.030 | ||

|

PSL2 |

0.43 | |||||

|

B |

0.22 |

1.20 |

0.025 |

0.015 | ||

|

×42 |

0.22 |

1.30 |

0.025 |

0.015 | ||

|

×46,×52,×56, X60 |

0.22 |

1.40 |

0.025 |

0.015 | ||

|

X65 |

0.22 |

1.45 |

0.025 |

0.015 | ||

|

X70 |

0.22 |

1.65 |

0.025 |

0.015 | ||

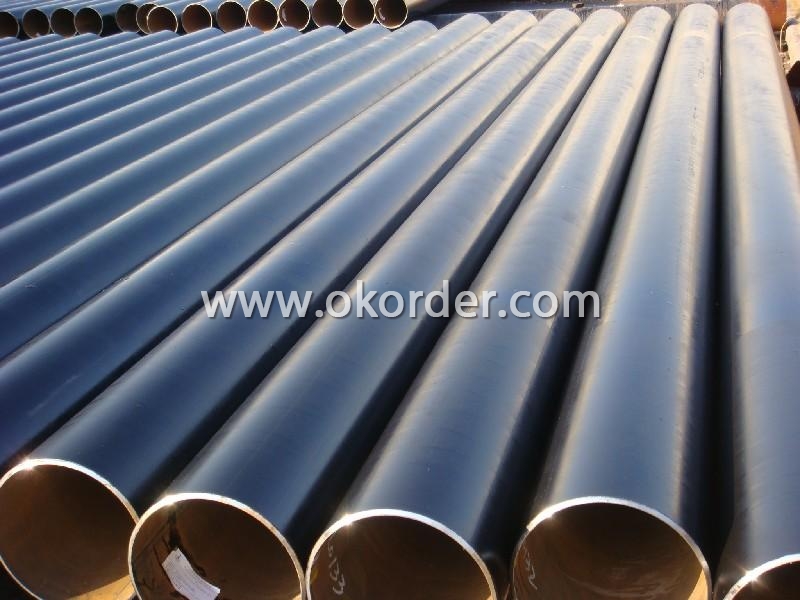

Usage/Applications Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

It is widely applied to line pipe in oil and sewage transportation, and it is used in Low pressure liquid and gassy transportation and it is also good Structure pipe in building and bridge field.

It also can be used for conveying gas, water and petroleum for oil and natural gas industries

Packaging & Delivery Of High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries:

Packaging: with anti-rust painting and with plastic caps, or with PVC package, or hot dipped galvanized, or 3 PE coating

Delivery: by containers or by bulk vessel

- Q: How are steel pipes transported and stored?

- Steel pipes are typically transported using trucks, trains, or ships, depending on the distance and quantity. These pipes are often stacked and secured with straps or chains during transportation to prevent any movement or damage. When it comes to storage, steel pipes are commonly stored in outdoor yards or warehouses. They are usually organized in neat rows or stacked on racks to maximize space and facilitate easy access. Additionally, pipes may be covered with weather-resistant materials to protect them from rust or corrosion during storage.

- Q: Seamless steel pipe is how to do it?

- Probably with 10, 20, 30, 35, 45 and other high-quality carbon steel, 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other composite steel hot-rolled or cold rolled.

- Q: Are the welded and galvanized tubes the same weight?

- The same specifications of welded pipe and galvanized pipe weight is not the same, the general welding tube weight, galvanized pipe light.

- Q: How are steel pipes used in the manufacturing of chemical processing plants?

- Steel pipes are commonly used in chemical processing plants for various purposes such as transporting fluids, gases, and chemicals within the facility. They are utilized for the safe and efficient transfer of raw materials, intermediate products, and final products throughout different stages of the manufacturing process. Steel pipes provide excellent strength, durability, and resistance to corrosion, making them suitable for handling corrosive materials and operating under high pressure and temperature conditions. Additionally, steel pipes can be welded and connected easily, allowing for customized configurations and efficient installation in chemical processing plants.

- Q: What's the actual size of the DN25?

- Steel pipe production technology development began in the bicycle manufacturing industry rise, early nineteenth Century during the oil development, the two world war ships, boilers, aircraft manufacturing, manufacturing of power boiler after the Second World War, the development of chemical industry, petroleum and natural gas drilling and mining and transportation, are promoted in production the quality and variety, the development of steel tube industry.

- Q: Can steel pipes be painted or coated?

- Yes, steel pipes can be painted or coated. Painting or coating steel pipes helps to protect them from corrosion, rust, and other environmental factors. It also enhances their aesthetic appearance and can be used to indicate the type of pipe or its function.

- Q: What are the common defects found in steel pipes?

- Some common defects found in steel pipes include corrosion, cracks, pitting, scaling, and distortion.

- Q: How are steel pipes used in agriculture?

- Various purposes in agriculture make steel pipes widely used, with one common application being irrigation systems. These pipes, known for their durability and ability to withstand water pressure, transport water from wells or reservoirs to different areas of farms, enabling efficient water distribution over long distances. Furthermore, steel pipes find utility in agricultural drainage systems. By removing excess water from fields, they prevent waterlogging and ensure proper drainage. Their resistance to corrosion is particularly significant in agricultural settings, where exposure to moisture and various chemicals is common. Moreover, steel pipes serve a vital purpose in the construction of greenhouse structures. They provide structural support for the greenhouse framework and facilitate the installation of irrigation systems and other equipment. The strength and sturdiness of steel pipes enable them to withstand harsh weather conditions, making them an ideal choice for greenhouse construction. Additionally, livestock farming benefits from the use of steel pipes. They are frequently employed in the creation of fences and enclosures for animals, providing a secure and long-lasting barrier. Steel pipes also play a crucial role in the construction of animal shelters and barns. To summarize, steel pipes play a crucial and versatile role in agriculture. They are integral components in irrigation systems, drainage systems, greenhouse construction, and livestock farming. Thanks to their durability, strength, and resistance to corrosion, steel pipes are an excellent choice for a wide range of agricultural applications.

- Q: Seamless steel pipe 8162 and 8163 what is the difference?

- 8163 GB is fluid delivery tube, need to use eddy current detection, fluid transport, liquid, gas, solid, such as natural gas, water, gas, coal and stone, 8162 and 8163 of the popular point that is 8163 more than 8162 senior, 8163 inspection, 8162 inspection. I hope you understand!

- Q: What is a tight steel tube?

- The fully enclosed steel tube is called "sleeve connection steel pipe". The English abbreviation is JDG. The sleeve between the pipe and the pipe is fastened by screws. The current specification is the construction and acceptance rules of CECS 120:2007 sleeve steel conduit pipe line

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 1980 |

| Annual Output Value | Above Three Million To Five Million RMB |

| Main Markets | Main land |

| Company Certifications | Certificate of Conformity; API 5CT |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-40% |

| No.of Employees in Trade Department | 1400 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 1500 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | CNPC;Sinopec Group |

| Product Price Range | Average |

Send your message to us

High Quality API 5L LSAW Welded Steel Pipes For Oil And Natural Gas Industries

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 m.t. m.t.

- Supply Capability:

- Based On Order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords