Schedule 40 Seamless Carbon Steel Pipe A335 J55 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

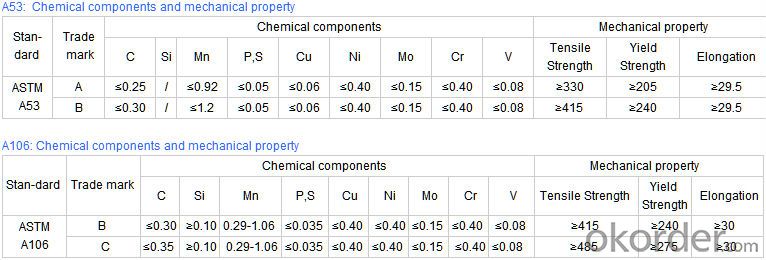

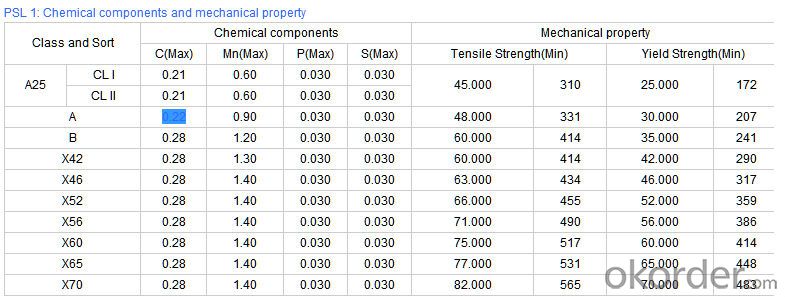

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: How do you calculate the pipe deflection for steel pipes?

- To determine the pipe deflection of steel pipes, various factors must be taken into account. Pipe deflection refers to the bending or displacement that occurs when a load is applied. The following steps outline the process for calculating pipe deflection: 1. Obtain the steel pipe properties: Familiarize yourself with the material properties of the steel pipe, including its Young's modulus (E) and moment of inertia (I). Young's modulus denotes the material's stiffness, while the moment of inertia measures its resistance to bending. 2. Identify the applied load: Determine the nature and magnitude of the load that will be exerted on the pipe. This may encompass internal pressure, external loads, or thermal expansion. 3. Utilize the appropriate formula: Depending on the load type and pipe support conditions, the suitable formula must be employed to calculate the deflection. For instance, if the pipe is simply supported (fixed at both ends), the formula δ = (5 * w * L^4) / (384 * E * I) can be used. Here, δ represents the deflection, w signifies the load per unit length, L denotes the pipe length, and E and I refer to the previously mentioned material properties. 4. Input values and compute: Insert the load, pipe length, and material properties into the formula. By doing so, the deflection of the steel pipe can be determined. It is crucial to note that calculating pipe deflection is a complex procedure that necessitates expertise in structural engineering. Therefore, it is advisable to consult a professional engineer or employ specialized software for accurate and reliable results.

- Q: Can steel pipes be used for underground gas distribution?

- Yes, steel pipes can be used for underground gas distribution. Steel pipes are commonly used for gas distribution as they are strong, durable, and can withstand high pressure. Additionally, steel pipes have excellent resistance to corrosion, which is crucial for underground installations. However, it is important to ensure proper coating and insulation to prevent any potential damage or leakage.

- Q: Can steel pipes be used for underground cable ducting?

- Yes, steel pipes can be used for underground cable ducting. Steel pipes are commonly used for underground cable ducting due to their durability and strength. They provide a protective casing for the cables, preventing damage from external factors such as moisture, pressure, and environmental elements. Steel pipes are also resistant to corrosion, which makes them a suitable choice for long-term use underground. Additionally, steel pipes can withstand heavy loads, making them ideal for areas where cables may be subjected to high pressure or weight. However, it is important to consider factors such as soil conditions, installation requirements, and the specific needs of the cable system before choosing steel pipes for underground cable ducting.

- Q: How are steel pipes used in stadium construction?

- Steel pipes are commonly used in stadium construction for various purposes such as structural support, roofing, and plumbing systems. They provide strength and durability to the overall structure of the stadium, allowing it to withstand heavy loads and adverse weather conditions. Steel pipes are also used for the installation of HVAC systems, water supply lines, and drainage systems within the stadium.

- Q: What is the maximum temperature and pressure that steel pipes can withstand?

- The maximum temperature and pressure that steel pipes can handle differ based on the specific grade and type of steel utilized. Nevertheless, steel pipes generally have the ability to withstand high temperatures and pressures due to their robust and long-lasting nature. In applications where high temperatures are involved, like in steam or heat transfer systems, steel pipes can typically endure temperatures up to 1000 degrees Celsius (1832 degrees Fahrenheit) or even higher. It is important to note that the exact temperature limit may fluctuate depending on the steel's alloy composition and heat treatment. In terms of pressure, steel pipes are renowned for their exceptional strength and ability to resist internal and external pressure. The maximum pressure that steel pipes can handle will depend on factors such as pipe diameter, wall thickness, and material strength. In industrial applications, steel pipes can handle pressures ranging from a few hundred psi (pounds per square inch) to several thousand psi. To ensure the safe operation of steel pipes under high temperatures and pressures, it is vital to adhere to industry standards and guidelines, as well as conduct regular inspections and maintenance. Seeking advice from engineers and professionals experienced in steel pipe systems can provide more specific information regarding the maximum temperature and pressure limits for a particular steel pipe application.

- Q: Can steel pipes be used for underground water supply pipelines?

- Yes, steel pipes can be used for underground water supply pipelines. Steel pipes are commonly used for water supply systems due to their durability, strength, and resistance to corrosion. They can withstand high pressure and are capable of carrying large volumes of water. Additionally, steel pipes are also available in various sizes and thicknesses, allowing for flexibility in designing and installing underground water supply pipelines. However, it is important to ensure that the steel pipes are properly coated or lined to prevent corrosion and maintain the quality of the water being transported. Regular inspections and maintenance should also be conducted to prevent any potential issues with the steel pipes.

- Q: What's the difference between seamless steel pipe and welded pipe?

- Welded steel pipe, also known as welded pipe, is made of steel or strip after the formation of welding welded steel pipe, usually 6 meters in length. Welded steel pipe production technology is simple, high production efficiency, varieties and specifications, equipment investment is less, but the general strength is lower than seamless steel pipe.

- Q: Can steel pipes be used for solar energy systems?

- Yes, steel pipes can be used for solar energy systems. Steel pipes are commonly used for the construction of solar water heating systems and solar thermal collectors. They are durable, resistant to corrosion, and can efficiently transport hot water or heat transfer fluids, making them suitable for various solar energy applications.

- Q: What are the advantages of using stainless steel pipes?

- There are several advantages of using stainless steel pipes. Firstly, stainless steel pipes have excellent corrosion resistance, making them suitable for a wide range of applications, including industrial, commercial, and residential plumbing systems. They can withstand harsh environments, chemicals, and high temperatures without deteriorating or rusting. Secondly, stainless steel pipes have high strength and durability, ensuring long-term reliability and reducing the need for frequent repairs or replacements. They can handle high pressure and stress, making them suitable for transporting fluids and gases in various industries. Additionally, stainless steel pipes are hygienic and easy to clean, making them ideal for applications in the food, beverage, and pharmaceutical industries. They are resistant to bacterial growth and contamination, ensuring the integrity and safety of the transported materials. Furthermore, stainless steel pipes are aesthetically pleasing and can be easily customized to fit different design requirements. They offer a sleek and modern appearance, making them suitable for architectural and decorative purposes. Overall, the advantages of using stainless steel pipes include corrosion resistance, durability, strength, hygiene, and aesthetic appeal, making them a reliable and versatile choice for various industries and applications.

- Q: How are steel pipes used in transportation?

- Steel pipes are commonly used in transportation for various purposes. They are used in the construction of pipelines for transporting fluids, such as oil, gas, and water, over long distances. Steel pipes are also utilized in the manufacturing of vehicle components, including exhaust systems, chassis, and suspension parts. Additionally, steel pipes can be found in infrastructure projects like bridges and tunnels, providing structural support for transportation networks.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe A335 J55 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords