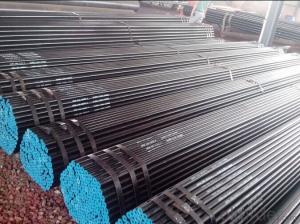

Seamless Carbon And Alloy Steel Mechanical Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Seamless Carbon And Alloy Steel Mechanical Tubing

ASTM A179 Seamless Carbon and Alloy Steel Mechanical Tubing

JIS G3441 Alloy steel tubes for machine purposes

MECHANICAL SEAMLESS STEEL TUBING

Usage of Seamless Carbon And Alloy Steel Mechanical Tubing

Applicable to the general structure, mechanical structure with seamless steel tubes.

Quality Standard of Seamless Carbon And Alloy Steel Mechanical Tubing

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A519 Seamless Carbon and Alloy Steel Mechanical Tubing

GB/T8162 Seamless Steel Tubes for Structural Purposes

JIS G3441 Alloy steel tubes for machine purposes

JIS G3444 Carbon steel tubes for general structural purposes

JIS G3445 Carbon steel tubes for machine structural purposes

DIN 2391 Seamless Precision Steel Tubes

EN10305 Steel tubes for precision applications. Technical delivery conditions. Seamless cold drawn tubes

EN 10210:Seamless structural steel pipes

Welcome to here: cheeralli at hnssd dot com. thanks

- Q: What is the difference between API 5L and ASTM A53 steel pipes?

- API 5L and ASTM A53 are two widely used standards for carbon steel pipes. While they both serve similar purposes, there are some key differences between them. 1. Scope: API 5L covers seamless and welded steel pipes for transportation of oil, gas, water, and other fluids. It also includes plain-end, threaded-end, and belled-end pipe types. On the other hand, ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipes used for mechanical and pressure applications. 2. Manufacturing process: API 5L pipe is produced through a hot-rolling process, whereas ASTM A53 pipe is produced through a hot-rolling or cold-drawing process. This difference in manufacturing process affects the pipe's chemical composition and mechanical properties. 3. Chemical composition: API 5L pipe typically has a higher carbon content compared to ASTM A53 pipe. This is because API 5L pipe is used for conveying oil, gas, and water, which often require higher strength and durability. ASTM A53 pipe, on the other hand, is used for mechanical and pressure applications, where lower carbon content is suitable. 4. Mechanical properties: API 5L pipe has higher minimum yield strength and tensile strength compared to ASTM A53 pipe. This is due to the higher carbon content and stricter manufacturing process of API 5L pipe. ASTM A53 pipe has lower yield and tensile strength requirements, making it more suitable for general-purpose applications. 5. Coating options: API 5L pipe can be produced with various coating options such as black varnish, 3PE, FBE, and others, depending on the application requirements. ASTM A53 pipe is usually hot-dipped galvanized for corrosion resistance. In summary, API 5L and ASTM A53 steel pipes have different scopes, manufacturing processes, chemical compositions, mechanical properties, and coating options. Choosing the right pipe depends on the specific application requirements, such as the type of fluid being transported, the operating conditions, and the desired strength and durability.

- Q: How do steel pipes perform in extreme weather conditions?

- Steel pipes are highly resilient and perform exceptionally well in extreme weather conditions. They have excellent resistance to corrosion, impact, and temperature variations, making them ideal for withstanding harsh environments such as extreme heat, cold, and heavy rainfall. Moreover, steel pipes are known for their durability and strength, ensuring that they can withstand the forces exerted by high winds, snow, and even seismic activities. Overall, steel pipes are a reliable choice for various applications in extreme weather conditions.

- Q: How are steel pipes sized and classified?

- Steel pipes are sized and classified based on their outer diameter, wall thickness, and length. The sizing is done using standard measurements such as nominal pipe size (NPS) or nominal diameter (DN). Classification is determined by factors such as the pipe's pressure rating, material composition, and intended use. This helps ensure compatibility and proper installation in various applications such as plumbing, construction, and industrial processes.

- Q: How are steel pipes used in plumbing?

- Steel pipes are commonly used in plumbing systems to transport water, gas, and waste materials. They are durable, strong, and resistant to corrosion, making them suitable for both residential and commercial plumbing applications. Steel pipes are typically used for water supply lines, drainage systems, and venting pipes, ensuring efficient and reliable plumbing infrastructure.

- Q: What are the different methods of insulation for steel pipes?

- There are several methods of insulating steel pipes, including applying a thermal insulation coating, using pipe wraps or jackets, using foam insulation, or utilizing heat shrink sleeves.

- Q: Are steel pipes resistant to impact?

- Yes, steel pipes are generally resistant to impact due to their strong and durable nature. They can withstand heavy loads and external forces, making them suitable for applications that involve high-pressure environments or potential impact scenarios.

- Q: How are steel pipes used in the manufacturing of boilers?

- Due to their strength, durability, and heat-resistant properties, steel pipes are essential components in the manufacturing of boilers. Boilers are utilized in various industrial and commercial applications to generate steam or heat water. The construction of boiler tubes is where steel pipes are primarily employed, as they function as the main heat transfer medium. Considering the high temperatures and pressure that these tubes are subjected to, it is crucial to use a material that can withstand such extreme conditions. Steel, with its excellent mechanical properties and corrosion resistance, is the ideal choice for this purpose. To create the boiler tubes, the manufacturing process involves shaping and sizing the steel pipes accordingly. These tubes are then connected to form a network of channels through which hot gases or water can flow. Depending on the boiler design requirements, the steel pipes utilized in this process are often seamless or welded. For the safety and efficiency of the system, the steel pipes used in boilers must meet stringent quality standards. They are subjected to tests to ensure their ability to withstand high pressure, temperature, and corrosion. Furthermore, inspections and tests such as ultrasonic testing and radiographic examination are conducted to identify any defects or flaws that might compromise the performance of the boiler. In conclusion, steel pipes play a critical role in the manufacturing of boilers by serving as the primary material for boiler tubes. Their strength, durability, and heat-resistant properties make them suitable for enduring high temperatures and pressure. These pipes undergo rigorous testing to guarantee their quality and reliability in creating efficient and safe boiler systems.

- Q: How are steel pipes used in structural applications?

- Steel pipes are commonly used in structural applications due to their strength, durability, and versatility. They are often used as columns, beams, and braces in buildings, bridges, and other structures. Steel pipes provide excellent load-bearing capacity and can withstand high levels of stress and pressure, making them ideal for supporting heavy loads. Additionally, their hollow cylindrical shape allows for easy installation and provides space for utilities such as electrical wiring or plumbing. Overall, steel pipes contribute to the stability and integrity of structures, ensuring their safety and longevity.

- Q: How are steel pipes used in the construction of power plants?

- Steel pipes are used in the construction of power plants to transport various fluids, such as water, steam, and fuel, throughout the facility. They are essential for ensuring a reliable and efficient flow of these substances, which are crucial for the operation of power generation equipment. Additionally, steel pipes are also used for structural support and to create ventilation and exhaust systems within the power plant.

- Q: How are steel pipes used in the manufacturing of agricultural machinery and equipment?

- Steel pipes are widely used in the manufacturing of agricultural machinery and equipment due to their various beneficial properties. These pipes are utilized in several ways to enhance the efficiency and durability of agricultural machinery. One of the primary uses of steel pipes in agricultural machinery is for the construction of frames and chassis. The high strength and structural integrity of steel pipes make them ideal for supporting heavy loads and withstanding the rigorous conditions often encountered in agricultural operations. Whether it is a tractor, combine harvester, or tillage equipment, steel pipe frames provide the necessary stability and sturdiness required for these machines to perform efficiently in the field. Steel pipes are also commonly used in the hydraulic systems of agricultural machinery. These pipes serve as conduits for hydraulic fluids, allowing for the smooth and reliable operation of various components such as hydraulic cylinders, pumps, and motors. Due to their resistance to corrosion and high pressure, steel pipes ensure the longevity of hydraulic systems, reducing maintenance and repair costs for agricultural machinery. Furthermore, steel pipes find applications in the exhaust systems of agricultural equipment. The exhaust gases produced by engines need to be safely and efficiently expelled to minimize environmental impact and maintain engine performance. Steel pipes with appropriate thickness and thermal resistance are used to construct exhaust systems, allowing for the effective removal of exhaust gases and reducing noise pollution. In addition, steel pipes are utilized in the manufacturing of irrigation systems and equipment used in agriculture. Whether it is for transporting water from a source to the fields or distributing water to crops through sprinklers or drip irrigation, steel pipes offer the necessary durability and resistance to pressure, ensuring efficient water delivery and minimizing leaks. Overall, the use of steel pipes in the manufacturing of agricultural machinery and equipment is crucial for enhancing their performance, durability, and efficiency. The strength, structural integrity, resistance to corrosion, and high pressure capabilities of steel pipes make them indispensable components in various applications within the agricultural sector.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2005 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 390People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM not offered |

| Product Price Range | Average |

Send your message to us

Seamless Carbon And Alloy Steel Mechanical Tubing

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords