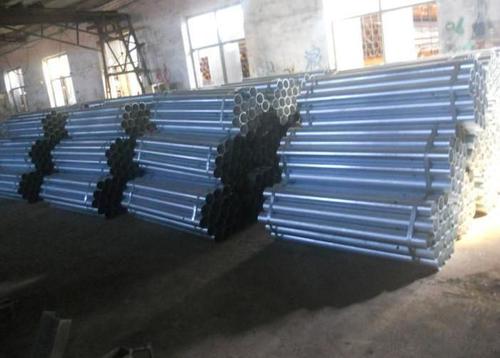

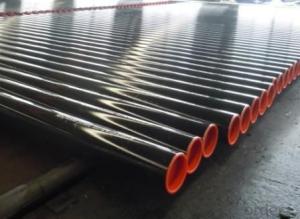

High Quality ASTM A53 ERW Welded Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ERW Welded Steel Pipes

Application of High Quality ASTM A53 ERW Welded Steel Pipe

It is widely applied to line pipe and casing and tubing in oil transportation and casing field, and it is used in Low, high pressure liquid and gassy transportation and it is also good Structure pipe (for furniture, window, door, building , bridge, mechanical etc).

Package: bundles with anti-rust painting and with plastic caps

Standard of High Quality ASTM A53 ERW Welded Steel Pipe

API SPEC 5L, API SPEC 5CT, ASTM A53, GB/T9711.1

SteelGrade of High Quality ASTM A53 ERW Welded Steel Pipe

API SPEC 5L: B, X42, X46, X52, X56, X60, X65

API SPEC 5CT: J55, K55, N80, L80-1

ASTM A53: A, B, C

GB/T9711.1:L242、L290、L320、L360、L390、L415、L450

Sizes of pipes of High Quality ASTM A53 ERW Welded Steel Pipe

*Remark: Besides below sizes, we also can arrange production based on requirement of customers

|

OD |

WT |

WEIGHT | ||||

|

INCH |

MM |

SCH |

MM |

INCH |

KG/M |

LB/INCH |

|

1 1/2” |

48.3 |

STD-40 |

3.68 |

0.145 |

4.09 |

2.75 |

|

1 1/2” |

48.3 |

XS-80 |

5.08 |

0.2 |

5.47 |

3.68 |

|

2” |

60.3 |

STD-40 |

3.91 |

0.154 |

5.49 |

3.69 |

|

2” |

60.3 |

XS-80 |

5.54 |

0.218 |

7.56 |

5.08 |

|

2 1/2” |

73 |

STD-40 |

5.16 |

0.203 |

8.72 |

5.86 |

|

2 1/2” |

73 |

XS-80 |

7.01 |

0.276 |

11.52 |

7.74 |

|

3” |

88.9 |

STD-40 |

5.49 |

0.216 |

11.41 |

7.67 |

|

3” |

88.9 |

XS-80 |

7.62 |

0.3 |

15.43 |

10.37 |

|

3 1/2” |

101.6 |

STD-40 |

5.74 |

0.226 |

13.71 |

9.21 |

|

3 1/2” |

101.6 |

XS-80 |

8.08 |

0.318 |

18.83 |

12.65 |

|

4” |

114.3 |

STD-40 |

6.02 |

0.237 |

16.24 |

10.91 |

|

4” |

114.3 |

XS-80 |

8.56 |

0.337 |

22.55 |

15.15 |

|

5” |

141.3 |

STD-40 |

6.55 |

0.258 |

21.99 |

14.78 |

|

5” |

141.3 |

XS-80 |

9.53 |

0.375 |

31.28 |

21.02 |

|

6” |

168.3 |

STD-40 |

7.11 |

0.28 |

28.55 |

19.19 |

|

6” |

168.3 |

XS-80 |

10.97 |

0.432 |

42.99 |

28.89 |

|

8” |

219.1 |

STD-40 |

8.18 |

0.322 |

42.98 |

28.88 |

|

8” |

219.1 |

XS-80 |

12.7 |

0.5 |

65.3 |

43.88 |

|

10” |

273 |

STD-40 |

9.27 |

0.365 |

60.9 |

40.92 |

|

10” |

273 |

80 |

15.09 |

0.594 |

96.95 |

65.15 |

|

12” |

323.8 |

STD |

9.53 |

0.375 |

74.61 |

50.13 |

|

12” |

323.8 |

40 |

10.31 |

0.406 |

80.51 |

54.1 |

|

12” |

323.8 |

XS |

12.7 |

0.5 |

98.42 |

66.14 |

|

12” |

323.8 |

80 |

17.48 |

0.688 |

133.38 |

89.63 |

|

14” |

355.6 |

40 |

11.13 |

0.438 |

95.51 |

64.18 |

|

14” |

355.6 |

XS |

12.7 |

0.5 |

108.48 |

72.9 |

|

14” |

355.6 |

80 |

19.05 |

0.75 |

159.71 |

107.32 |

|

16” |

406.4 |

XS-40 |

12.7 |

0.5 |

124.55 |

83.69 |

|

18” |

457 |

STD |

9.53 |

0.375 |

106.23 |

71.38 |

|

18” |

457 |

40 |

14.27 |

0.562 |

157.38 |

105.75 |

|

18” |

457 |

80 |

23.83 |

0.938 |

257.13 |

172.78 |

|

20” |

508 |

40 |

15.09 |

0.594 |

185.28 |

124.5 |

|

20” |

508 |

80 |

26.19 |

1.031 |

314.33 |

211.22 |

Standard: GB/9711.1

Mechanical Properties of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

(MPa) |

(MPa) |

Min(%) |

|

Yield strength |

Tensile Strength |

Elongation | ||

|

GB/T9711.1 |

L245 |

≥245 |

≥415 |

21 |

|

L290 |

≥290 |

≥415 |

21 | |

|

L320 |

≥320 |

≥435 |

20 | |

|

L360 |

≥360 |

≥460 |

19 | |

|

L390 |

≥390 |

≥490 |

18 | |

|

L415 |

≥415 |

≥520 |

17 | |

|

L450 |

≥450 |

≥535 |

17 | |

|

L485 |

≥485 |

≥570 |

17 |

Chemical Composition(%) of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

C |

Mn |

P |

S |

|

Max |

Max |

Max |

Max | ||

|

GB/T9711.1 |

L245 |

0.26 |

0.15 |

0.030 |

0.030 |

|

L290 |

0.28 |

1.25 |

0.030 |

0.030 | |

|

L320, L360 |

0.30 |

1.25 |

0.030 |

0.030 | |

|

L390, L415 |

0.26 |

1.35 |

0.030 |

0.030 | |

|

L450 |

0.26 |

1.40 |

0.030 |

0.030 | |

|

L485 |

0.23 |

1.60 |

0.025 |

0.030 |

Standard: GB/9711.2

Mechanical Properties of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

(MPa) Yield strength |

(MPa) Tensile Strength |

Min(%) Elongation | ||

|

GB/T9711.2 |

Rt0.5Min |

Rt0.5Max |

RmMin |

Rt0.5/Rm Max |

||

|

L245 |

245 |

440 |

0.80 |

22 | ||

|

L245 |

0.85 | |||||

|

L290 |

290 |

440 |

0.80 |

21 | ||

|

L290 |

0.85 | |||||

|

L360 |

360 |

510 |

0.85 |

20 | ||

|

L360 |

0.85 | |||||

|

L415 |

415 |

565 |

0.85 |

18 | ||

|

L415 |

0.85 | |||||

|

L450 |

450 |

570 |

535 |

0.87 |

18 | |

|

L485 |

485 |

605 |

570 |

0.90 |

18 | |

Chemical Composition (%) of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

C |

Mn |

P |

S |

V |

Nb |

Ti |

CEV |

|

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Max | ||

|

GB/T9711.2 |

L245NB |

0.16 |

1.1 |

0.025 |

0.020 |

- |

- |

- |

0.42 |

|

L290NB |

0.17 |

1.2 |

0.025 |

0.020 |

0.05 |

0.05 |

0.04 |

0.42 | |

|

L360NB |

0.20 |

1.6 |

0.025 |

0.020 |

0.10 |

0.05 |

0.04 |

0.45 | |

|

L415NB |

0.21 |

1.6 |

0.025 |

0.020 |

0.15 |

0.05 |

0.04 |

- | |

|

L245NB, L290NB |

0.16 |

1.5 |

0.025 |

0.020 |

0.04 |

0.04 |

- |

0.4 | |

|

L360NB |

0.16 |

1.6 |

0.025 |

0.020 |

0.05 |

0.05 |

0.04 |

0.41 | |

|

L415NB |

0.16 |

1.6 |

0.025 |

0.020 |

0.08 |

0.05 |

0.06 |

0.42 | |

|

L450NB |

0.16 |

1.6 |

0.025 |

0.020 |

0.10 |

0.05 |

0.06 |

0.43 | |

|

L485NB |

0.16 |

1.7 |

0.025 |

0.020 |

0.10 |

0.06 |

0.06 |

0.43 |

Standard: ASTM A53

Mechanical Properties of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

(MPa) |

(MPa) |

|

Yield strength |

Tensile Strength | ||

|

ASTM A53M |

A |

205 |

330 |

|

B |

240 |

415 |

Chemical Composition(%) of High Quality ASTM A53 ERW Welded Steel Pipe

|

Standard |

Grade |

C |

Mn |

P |

S |

V |

Ni |

Cu |

Cr |

Mo |

|

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Max |

Max | ||

|

ASTM A53M |

A |

0.25 |

0.95 |

0.05 |

0.045 |

0.08 |

0.4 |

0.5 |

0.4 |

0.15 |

|

B |

0.30 |

1.20 |

0.05 |

0.045 |

0.08 |

0.4 |

0.5 |

0.4 |

0.15 |

- Q: How are steel pipes threaded for connection?

- Steel pipes are threaded for connection using a threading machine that cuts grooves into the pipe's outer surface. The machine rotates the pipe while a die cuts the threads, creating a spiral pattern. This threading allows pipes to be securely connected by screwing them together, providing a tight and leak-free joint.

- Q: How are steel pipes used in the construction of gas distribution networks?

- Steel pipes are commonly used in the construction of gas distribution networks due to their strength, durability, and ability to withstand high pressure. These pipes are used to transport natural gas from the source to homes, businesses, and industries safely and efficiently. They are often buried underground and connected through a network of pipes, allowing for the distribution of gas to various locations. The corrosion-resistant nature of steel ensures the longevity of the pipes, making them a reliable choice for gas distribution infrastructure.

- Q: Can steel pipes be used for steam distribution?

- Yes, steel pipes can be used for steam distribution. Steel pipes are commonly used in steam distribution systems due to their high strength, durability, and resistance to high temperatures and pressure. They can effectively handle the transportation of steam in various industries such as power generation, chemical processing, and heating systems.

- Q: How are steel pipes connected together?

- Steel pipes are typically connected together using various methods such as welding, threading, or using mechanical fittings, depending on the specific application and requirements.

- Q: Can steel pipes be used for oil refinery applications?

- Yes, steel pipes can be used for oil refinery applications. Steel pipes offer many advantages for oil refinery applications including high strength, durability, and resistance to corrosion. They are able to withstand high pressure and temperature conditions that are common in oil refinery operations. Steel pipes are also easy to transport and install, making them a popular choice for oil refinery projects. Additionally, steel pipes can be customized to meet specific requirements such as size, thickness, and coating, making them suitable for a wide range of oil refinery applications.

- Q: What is the process of coating steel pipes?

- The process of coating steel pipes involves several steps. First, the pipes are cleaned and prepared to remove any dirt, grease, or rust. Then, a primer is applied to the surface of the pipes to enhance adhesion. After the primer dries, a coating material such as epoxy, polyethylene, or zinc is applied using various methods like spraying, dipping, or wrapping. This coating material not only provides protection against corrosion but also acts as a barrier against external elements. Finally, the coated pipes are cured or dried to ensure the coating adheres properly and forms a durable layer, ready for use in various industries such as oil and gas, water supply, or construction.

- Q: What are the different types of flanges used with steel pipes?

- There are several types of flanges commonly used with steel pipes, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, and blind flanges. These flanges are used to connect and secure steel pipes in various industrial applications, each offering specific advantages depending on the requirements of the piping system.

- Q: Galvanized steel pipe, PPR pipe, PE pipe, U-PVC pipe and HDPE double wall corrugated pipe and what is the difference between the characteristics of

- Galvanized steel pipe is a kind of antirust steel pipe, often used in relatively high water supply pipeline or hot water pipeline, the price is higher, can use for at least 30 years;PPR pipe is a kind of polypropylene plastic, which is commonly used in environmental protection plastic pipes, but only suitable for low temperature occasions. It is mainly used for water supply;

- Q: How do you prevent steel pipes from freezing in cold climates?

- One way to prevent steel pipes from freezing in cold climates is by insulating them. Insulation materials such as foam or fiberglass can be wrapped around the pipes to prevent heat loss and keep them at a stable temperature. Additionally, using heat tape or cables can provide an extra layer of protection by applying low-level heat to the pipes. It is also important to ensure that pipes are properly sealed and any cracks or gaps are sealed to prevent cold air from entering and freezing the pipes.

- Q: What are the different pressure ratings for steel pipes?

- The different pressure ratings for steel pipes can vary depending on factors such as pipe size, wall thickness, and the type of steel used. Common pressure ratings for steel pipes range from 150 psi (pounds per square inch) to 2500 psi or higher.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2005 |

| Annual Output Value | Above 100 Million RMB |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese;Korean |

| b) Factory Information | |

| Factory Size: | 120mu |

| No. of Production Lines | 11 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High Average |

Send your message to us

High Quality ASTM A53 ERW Welded Steel Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- based on order m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords