Schedule 40 Seamless Carbon Steel Pipe A335P95 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

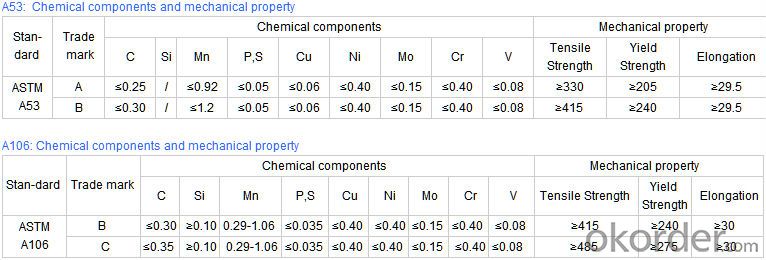

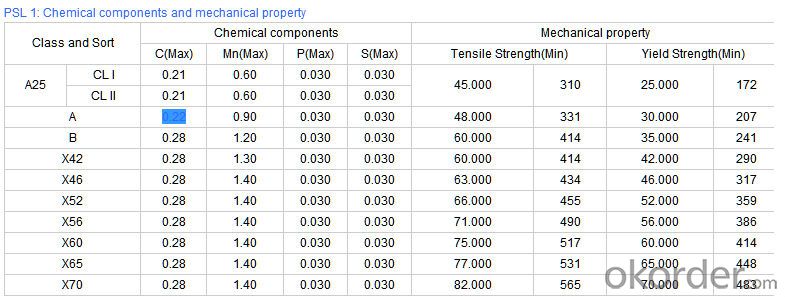

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: How are steel pipes used in the manufacturing of pressure vessels?

- Steel pipes are commonly used in the manufacturing of pressure vessels as they provide the necessary strength and durability to withstand high internal pressure. These pipes are welded or seamless and are often used as the main structural component of the vessel. They allow for the efficient flow of fluids or gases within the vessel and provide a reliable and secure containment system for various industrial applications.

- Q: How do steel pipes handle vibrations?

- The effectiveness of handling vibrations is a well-known attribute of steel pipes. Their strong and rigid nature enables them to withstand various types of vibrations, including mechanical vibrations and seismic activities. The structural integrity and strength of steel pipes are responsible for their resilience. Steel pipes possess high tensile strength, which allows them to resist deformation or breakage when exposed to vibrations. They also exhibit resistance to fatigue, meaning they can endure repeated vibrations without suffering significant damage. This quality makes steel pipes ideal for applications involving constant or cyclic vibrations, such as in industrial settings or for fluid transportation through pipelines. Furthermore, steel pipes have the added advantage of being able to dampen vibrations due to their mass. The weight of the steel pipe aids in absorbing and dissipating the energy generated by vibrations, preventing excessive movement or oscillation. This damping effect contributes to the overall stability and durability of the pipe system. Various measures can be taken to further enhance the ability of steel pipes to handle vibrations. These measures may include the utilization of vibration isolators or dampers, which are devices designed to reduce the transmission of vibrations from the surrounding environment. Additionally, proper installation techniques and regular maintenance can help ensure that steel pipes continue to function optimally under conditions prone to vibrations. In conclusion, steel pipes possess the necessary attributes to effectively handle vibrations, including strength, resistance to fatigue, and the ability to dampen vibrations. Their robustness and durability make them a reliable choice for applications where vibrations are a concern, guaranteeing the safe and efficient transportation of fluids or materials.

- Q: What are the different types of couplings used with steel pipes?

- There are several types of couplings used with steel pipes, including threaded couplings, slip-on couplings, compression couplings, and grooved couplings.

- Q: How are steel pipes used in the wastewater treatment industry?

- Steel pipes are commonly used in the wastewater treatment industry for various purposes, including the transportation of wastewater from one area to another, the distribution of treated water to different locations, and the construction of infrastructure such as pumping stations and treatment plants. Due to their durability, resistance to corrosion, and ability to withstand high pressure, steel pipes are essential components in the efficient and reliable operation of wastewater treatment systems.

- Q: Can steel pipes be used for firefighting systems?

- Yes, steel pipes can be used for firefighting systems. Steel pipes are commonly used for their durability and resistance to high temperatures, making them suitable for transporting water and other fire suppression agents. They are typically used in larger commercial or industrial buildings where the fire protection system requires a higher flow rate and pressure. Steel pipes also have the advantage of being able to withstand external forces and impacts, ensuring the integrity of the firefighting system. Additionally, steel pipes can be easily connected, making them convenient for installation and maintenance purposes. However, it is important to ensure that the steel pipes used for firefighting systems are properly treated to prevent corrosion and rusting, as this can compromise their effectiveness in an emergency situation. Regular inspections and maintenance should be conducted to ensure the reliability and functionality of the steel pipes within the firefighting system.

- Q: What are the common standards for manufacturing steel pipes?

- The common standards for manufacturing steel pipes include specifications set by international organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the European Committee for Standardization (EN). These standards cover aspects such as material composition, dimensions, mechanical properties, and testing methods to ensure quality and compatibility in steel pipe production.

- Q: How are steel pipes insulated against heat loss?

- Steel pipes can be insulated against heat loss using several methods. One common method is through the use of insulation materials such as mineral wool or fiberglass wraps. These materials are wrapped around the pipes to create a barrier that reduces heat transfer. Another method is the application of insulation coatings, such as foam or rubber coatings, directly onto the surface of the pipes. These coatings create a protective layer that minimizes heat loss. Additionally, thermal tape or heat-resistant tape can be used to seal any gaps or joints in the insulation, ensuring a continuous barrier against heat loss. Overall, insulating steel pipes against heat loss is essential to maintain the temperature of the fluid or gas being transported and to increase energy efficiency in various industries.

- Q: How do steel pipes handle thermal expansion?

- Steel pipes handle thermal expansion by expanding and contracting along their length due to changes in temperature. This expansion is accommodated by allowing the pipes to move freely or by using expansion joints, which can absorb the thermal expansion and prevent damage or failure.

- Q: What are the different methods of joining steel pipes for oil and gas pipelines?

- There are several different methods of joining steel pipes for oil and gas pipelines, including welding, threading, and flange connections. Welding involves heating the ends of the pipes and fusing them together, creating a strong and durable joint. Threading is a process where the ends of the pipes are threaded and screwed together, providing a secure connection. Flange connections involve using flanges, which are flat, circular discs with holes in the center, to connect the pipes. The flanges are bolted together, creating a tight seal. These methods are commonly used in the construction of oil and gas pipelines to ensure reliable and leak-free connections.

- Q: How are steel pipes used in the construction of power plants?

- Steel pipes are widely used in the construction of power plants as they serve multiple purposes. They are primarily used for transporting various fluids, such as water, steam, and fuel, throughout the plant. Steel pipes are also used for the construction of boilers, heat exchangers, and condensers, which are essential components in power generation. Additionally, steel pipes are utilized in the construction of cooling systems, air ventilation systems, and structural supports within power plants. Overall, steel pipes are crucial for the efficient and reliable operation of power plants.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe A335P95 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords