Schedule 40 Seamless Carbon Steel Pipe ST37 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 1.73 - 59.54 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 914.4 mm |

| Secondary Or Not: | Non-secondary | Application: | Fluid Pipe | ||

| Technique: | Hot Rolled | Certification: | API | Surface Treatment: | Galvanized,vanish covering, black painting, galvenized ect. |

| Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | Length: | 5-12m as per customer's requirements |

| SCH: | SCH10~160, STD, XS & XXS | Payment Terms: | L/C T/T | Supply Ability: | 5000 Ton/Tons per Week |

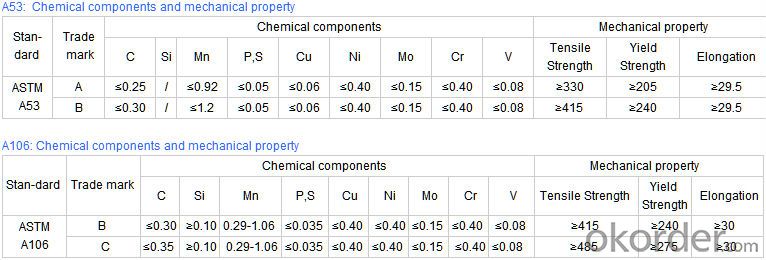

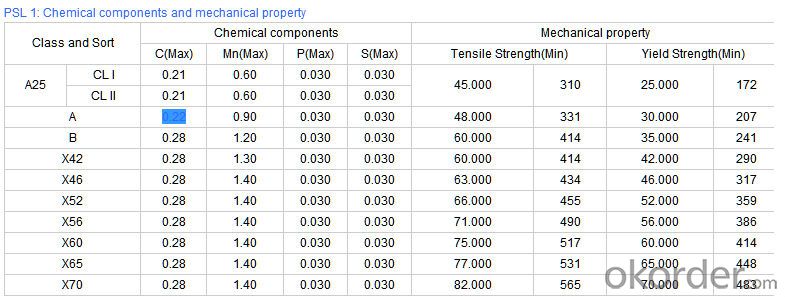

| Product: | pipe prices | Grade: | 10#,20#,45#,A106(B,C),A53(A,B),12Cr1MoV,12Cr1MoVG,12Cr2Mo,13CrMo44,13CrMo45,15CrMo,15CrMoG,St52,St52.4,10#-45#,A53-A369,Cr-Mo alloy,ST35-ST52 | Standard: | API 5CT,API 5L,ASTM A106-2006,ASTM A53-2007,DIN 17175,GB 3087-1999,GB 5130,GB 6479-2000,GB 9948-2006,GB/T 17396-1998,GB/T 5312-1999,GB/T 8162-1999,GB/T 8163-1999,API,ASTM,DIN,GB |

Packaging & Delivery

| Packaging Detail: | By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers. |

| Delivery Detail: | within 5-15 days |

Specifications

1.pipe prices

2.Supply Ability:5000 Tons per Week

3.Payment Terms:L/C T/T

High quality Carbon steel pipe, Best pipe prices

1) Application: Overheat pipe for low and mediumpressure boiler,boiling water pipe, locomotive smoke pipe(big and small),Carry gas ,water or oil in the industries of petroleum and natural gas etc

2) Materials: 10#, 20#, 45#, 15CrMo, 12Cr1MoV, 13CrMo44, 12Cr2Mo, 13CrMo45, 12Cr1MoVG, 15CrMoG, API J55, API K55, API N80, API L80, API P110

3)Pipe according to standard: GB 3087-1999, GB/T 8163-1999, GB/T 8162-1999, GB 9948-2006, GB/T 17396-1998, GB/T 5312-1999, GB 6479-2000, GB 5130, DIN 17175, API 5CT, API 5L .

4)Packing: By bundles, seaworthy wooden cases, steel framed cases, and simple packaging or according to the demand of the customers.

Technical Parameters of Seamless Steel Pipe

- Q: What is the difference between carbon steel pipes and stainless steel pipes?

- The main difference between carbon steel pipes and stainless steel pipes lies in their composition and properties. Carbon steel pipes are primarily made of iron and carbon, with small amounts of other elements. They are less expensive, have higher tensile strength, and are suitable for transporting fluids and gases in various industries. On the other hand, stainless steel pipes contain iron, chromium, and other alloying elements. They are more expensive, have higher corrosion resistance, and are commonly used in applications where hygiene, durability, and aesthetic appeal are essential, such as in the food, pharmaceutical, and architectural industries.

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used for constructing water wells due to their durability, strength, and resistance to corrosion. They can withstand high water pressure and provide a reliable and long-lasting solution for accessing underground water sources.

- Q: What is the average lifespan of steel pipes in different applications?

- The lifespan of steel pipes in different applications can vary due to various factors, such as the quality of the steel, the environment in which they are used, and the maintenance and care they receive. Water supply lines typically have steel pipes that can last around 50 to 70 years on average. These pipes are often made of high-quality steel and experience less corrosive environments. However, the presence of corrosive substances, water chemistry, and soil conditions can significantly impact their lifespan. For industrial applications like oil and gas pipelines, steel pipes generally have a lifespan ranging from 20 to 50 years. These pipes are exposed to aggressive environments with high temperatures, pressure, and corrosive substances. Extending their lifespan can be achieved through regular inspections, maintenance, and corrosion protection measures. In construction applications, steel pipes used for structural purposes can last an average of 50 to 100 years or longer. These pipes are designed to withstand heavy loads and are often safeguarded by coatings or insulation to prevent corrosion. It's important to understand that these are average lifespans, and individual pipes may have shorter or longer lifespans depending on specific conditions. Ensuring the longevity of steel pipes in different applications can be achieved through regular inspections, maintenance, and timely repairs or replacements when necessary.

- Q: What are the factors that affect the pressure rating of steel pipes?

- There are several factors that can affect the pressure rating of steel pipes. 1. Material strength: The strength of the steel used in the pipe construction plays a crucial role in determining its pressure rating. Higher strength steel can withstand higher pressure levels, whereas weaker grades of steel may have lower pressure ratings. 2. Wall thickness: The thickness of the pipe wall directly impacts its pressure rating. Thicker walls can handle higher pressure levels as they provide more resistance against the internal forces exerted by the fluid or gas flowing through the pipe. 3. Pipe diameter: The diameter of the steel pipe also influences its pressure rating. Generally, larger pipes have higher pressure ratings as they have a larger cross-sectional area to distribute the internal pressure forces. 4. Temperature: Elevated temperatures can significantly affect the pressure rating of steel pipes. High temperatures can weaken the steel material, reducing its overall strength and, consequently, its pressure rating. Therefore, it is important to consider the maximum operating temperature when determining the pressure rating of steel pipes. 5. Corrosion resistance: Corrosion can weaken the pipe material over time, leading to a decrease in its pressure rating. Various factors such as the type of fluid being transported, pH levels, and environmental conditions can impact the corrosion resistance of steel pipes. Utilizing corrosion-resistant coatings or selecting stainless steel pipes can help mitigate this factor. 6. Manufacturing standards: Compliance with recognized industry standards and specifications is crucial in determining the pressure rating of steel pipes. These standards ensure that the pipes are manufactured using proper techniques and materials, providing reliable and accurate pressure ratings. 7. External loads: External loads or forces acting on the pipes, such as soil settlement, traffic loads, or installation practices, can affect their pressure rating. Proper design and installation techniques, including adequate support and protection, are essential in ensuring the pipes can withstand these external forces without compromising their pressure rating. It is important to consider all these factors and consult relevant industry standards and guidelines to determine the appropriate pressure rating for steel pipes in different applications.

- Q: What is the maximum length of steel pipes available?

- The maximum length of steel pipes available can vary depending on the manufacturer and the specific requirements. However, standard lengths for steel pipes typically range from 18 to 24 feet.

- Q: What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Seamless tube is a strip of steel with a hollow cross section and no seams at all. The general is rolled into a cylindrical tube plate welding.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: What are the advantages of using steel pipes in the mining industry?

- There are several advantages of using steel pipes in the mining industry. Firstly, steel pipes are extremely durable and can withstand high-pressure environments, making them ideal for transporting materials such as water, slurry, and chemicals in mining operations. Secondly, steel pipes are resistant to corrosion, which is crucial in the mining industry where materials are often exposed to harsh conditions and abrasive substances. Additionally, steel pipes have a high heat tolerance, allowing them to handle hot materials without deformation or damage. Lastly, steel pipes are easy to install and maintain, reducing downtime and ensuring smooth operations in the mining industry.

- Q: What are the different grades of steel used for manufacturing pipes?

- The different grades of steel commonly used for manufacturing pipes include carbon steel, alloy steel, and stainless steel.

- Q: Can steel pipes be used for underground sewer lines?

- Indeed, underground sewer lines can certainly utilize steel pipes. Given their robustness, resilience, and resistance against corrosion, steel pipes are widely employed in sewer systems. They possess the capacity to withstand the immense burden of soil and external forces, rendering them highly suitable for subterranean purposes. Moreover, steel pipes boast an extended lifespan and excel in efficiently conveying wastewater and sewage over numerous years. However, it remains crucial to guarantee the appropriate coating or lining of these steel pipes to avert corrosion and further elongate their durability.

Send your message to us

Schedule 40 Seamless Carbon Steel Pipe ST37 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords