Rosette Scaffolding Formwork China Scaffolding Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rosette Scaffolding Formwork China Scaffolding Low Price

Circular Column Formwork Outrigger For Scaffolding With New Design

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels..

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

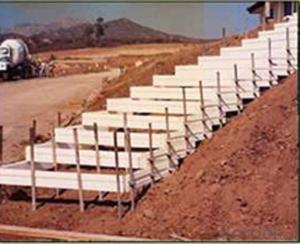

Rosette Scaffolding Formwork China Scaffolding Low Price

Rosette Scaffolding Formwork China Scaffolding Low Price

Rosette Scaffolding Formwork China Scaffolding Low Price

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Rosette Scaffolding Formwork China Scaffolding Low Price

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

FAQ Rosette Scaffolding Formwork China Scaffolding Low Price

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: What are the common material specifications for steel frame formwork components?

- The common material specifications for steel frame formwork components typically include high-strength steel, such as grade 50 or grade 80, to ensure durability and structural stability. Additionally, these components may have specific coatings or surface treatments to enhance corrosion resistance and prolong their lifespan.

- Q: Such as questions such as the younger brother tutor went abroad let me learn ABAQUS steel frame research for a long time can not find the steel frame model of the video and the information is really anxious to have the information of the great God for advice

- Set xn to meet xn>0, xn+4/[x (n+1)]<3 card

- Q: What are the different types of concrete additives and admixtures used with steel frame formwork?

- There are several different types of concrete additives and admixtures that can be used with steel frame formwork to enhance the properties and performance of the concrete. One common type of additive is a water reducer, also known as a plasticizer or superplasticizer. This additive helps to reduce the amount of water needed for a given mix, improving the workability and flowability of the concrete. It also increases the strength and durability of the final product. Another type of additive is an air-entraining agent. This helps to introduce microscopic air bubbles into the concrete, which improves its resistance to freeze-thaw cycles and enhances its workability. Accelerators and retarders are also frequently used additives. Accelerators, as the name suggests, speed up the setting and hardening process of the concrete, which can be beneficial in cold weather or when a quick turnaround time is required. Retarders, on the other hand, slow down the setting time, allowing for more time to work with the concrete and preventing it from drying out too quickly. Fiber additives can be used to increase the strength and durability of the concrete. These fibers, which can be made from materials such as steel, glass, or synthetic polymers, help to reinforce the concrete and prevent cracking. Admixtures such as corrosion inhibitors or shrinkage reducers can also be used with steel frame formwork to address specific issues. Corrosion inhibitors help to protect the steel reinforcement from corrosion, while shrinkage reducers help to minimize shrinkage and cracking in the concrete. Overall, the use of these additives and admixtures with steel frame formwork can greatly enhance the performance and durability of the concrete, making it more resistant to various environmental and structural challenges.

- Q: What are the different types of steel used in steel frame formwork systems?

- There are several types of steel commonly used in steel frame formwork systems. The choice of steel depends on factors such as load capacity, durability, and cost. 1. Mild Steel: This is the most common type of steel used in formwork systems. It is known for its strength and affordability. Mild steel is suitable for most construction applications and can handle moderate loads. 2. High-Strength Low-Alloy (HSLA) Steel: HSLA steel is a type of steel that offers higher strength and better corrosion resistance compared to mild steel. It is commonly used in applications that require increased load capacity and durability. 3. Alloy Steel: Alloy steel is made by adding elements such as chromium, nickel, or molybdenum to improve its mechanical properties. It offers increased strength, hardness, and resistance to wear and tear. Alloy steel is often used in heavy-duty formwork systems that require high load-bearing capacity. 4. Stainless Steel: Stainless steel is known for its excellent corrosion resistance. It is commonly used in formwork systems that are exposed to harsh environments, such as marine or chemical plants. Stainless steel is more expensive than other types of steel but provides long-lasting performance. 5. Carbon Steel: Carbon steel is a type of steel that contains carbon as the main alloying element. It offers good strength and durability, making it suitable for various formwork applications. Carbon steel is also commonly used in combination with other materials, such as concrete, to provide additional reinforcement. It is important to select the appropriate type of steel for a steel frame formwork system based on the specific requirements of the construction project. Factors such as load capacity, durability, and budget should be considered to ensure the success of the formwork system.

- Q: What are the different types of formwork corners used in steel frame formwork systems?

- There are several different types of formwork corners that are commonly used in steel frame formwork systems. These corners are designed to provide stability and support to the formwork structure, ensuring that the concrete can be poured and cured properly. 1. External corners: These corners are used to create 90-degree angles on the external faces of the formwork. They are usually made of steel or aluminum and are designed to be strong and durable. External corners are typically adjustable, allowing for flexibility in formwork design. 2. Internal corners: Similar to external corners, internal corners are used to create 90-degree angles on the internal faces of the formwork. They are also made of steel or aluminum and can be adjusted to fit the desired formwork shape. Internal corners are essential for creating precise and accurate formwork structures. 3. Column corners: Column corners are specifically designed for creating formwork around columns or pillars. These corners are shaped to fit the curvature of the column and provide support and stability to the formwork structure. Column corners are available in various sizes to accommodate different column diameters. 4. Wall corners: Wall corners are used to create corners in formwork structures that are not 90 degrees. They are typically adjustable, allowing for flexibility in formwork design. Wall corners are specially designed to provide stability and support in non-standard corner angles. 5. Beam corners: Beam corners are used to create corners in formwork structures that involve beams. They are designed to provide stability and support to the formwork system while accommodating the shape and size of the beams. Beam corners are available in various sizes to accommodate different beam dimensions. Overall, the different types of formwork corners in steel frame formwork systems ensure the structural integrity of the concrete formwork, allowing for the accurate and safe pouring of concrete.

- Q: How does steel frame formwork contribute to the strength and stability of a concrete structure?

- Steel frame formwork contributes to the strength and stability of a concrete structure by providing a rigid and durable framework for the concrete to be poured into. It ensures accurate alignment and support during the construction process, preventing any deformation or collapse. The steel frame also helps distribute the load evenly across the structure, enhancing its overall strength and stability. Additionally, the use of steel frame formwork allows for efficient construction practices, reducing the risk of errors and improving the quality of the final concrete structure.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier?

- When selecting the appropriate steel frame formwork supplier, some key considerations to keep in mind include the supplier's reputation and experience in the industry, the quality and durability of their products, their ability to meet project requirements and deadlines, their customer service and support, as well as the overall cost and value of their offerings. It is important to thoroughly research and evaluate different suppliers to ensure that they can provide the necessary expertise, reliability, and cost-effectiveness for the specific project needs.

- Q: What are the types of reinforced concrete bridge construction template

- Types of reinforced concrete bridge construction template:1, wood template;2, combination steel template;

- Q: Can steel frame formwork be used for circular columns?

- Circular columns can indeed be constructed using steel frame formwork. The versatility of steel frame formwork enables it to effortlessly adapt to various shapes and sizes, including circular columns. Its adjustability feature allows for easy customization to meet specific project needs. By utilizing adjustable steel frames, the formwork can be shaped to create a circular mold for pouring concrete and shaping circular columns. This renders steel frame formwork an appropriate option for construction endeavors involving circular column structures.

- Q: How does steel frame formwork accommodate for different concrete mix designs?

- Steel frame formwork can accommodate for different concrete mix designs by allowing for easy adjustment of the formwork panels. This means that the size and shape of the formwork can be modified to accommodate variations in the concrete mix design, such as different slump levels or aggregate sizes. Additionally, the steel frame formwork provides stability and strength, ensuring that it can withstand the pressure exerted by different concrete mix designs during pouring and curing.

Send your message to us

Rosette Scaffolding Formwork China Scaffolding Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords