Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Screw Jack Formwork Scaffolding China Low Price

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

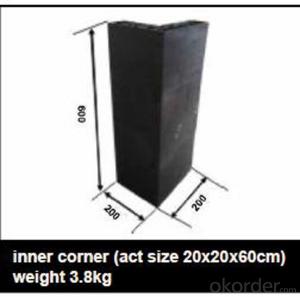

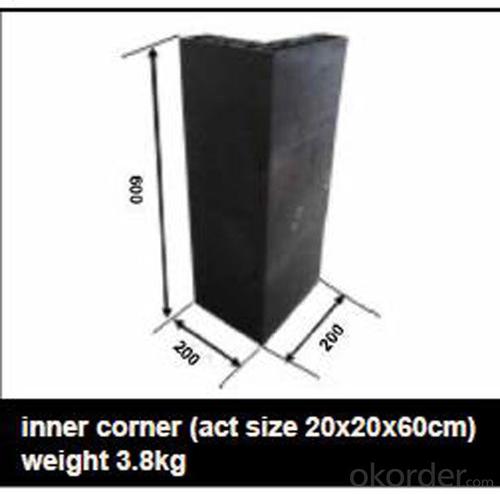

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Q: How does steel frame formwork contribute to the overall flexibility of a construction project?

- Steel frame formwork contributes to the overall flexibility of a construction project in several ways. Firstly, steel frame formwork is highly adaptable and can be easily customized to suit the specific requirements of different construction projects. This flexibility allows for the construction of various types of structures, such as buildings, bridges, and tunnels, with different shapes and sizes. Additionally, steel frame formwork is durable and can withstand the high pressure and loads exerted during the construction process. This durability enables the formwork to be reused multiple times, reducing the overall cost and time required for a project. The ability to reuse the formwork also allows for adjustments and modifications to be made during the construction process, providing greater flexibility in design changes or unforeseen circumstances that may arise. Furthermore, steel frame formwork provides a high level of accuracy and precision in the construction process. The formwork is designed to ensure the correct alignment and positioning of the concrete, resulting in consistent and high-quality finishes. This accuracy contributes to the overall flexibility of a construction project by allowing for efficient construction processes and minimizing the need for rework or corrections. Moreover, steel frame formwork offers enhanced safety features, such as built-in safety platforms and guardrails, which provide a secure working environment for construction workers. This safety aspect allows for greater flexibility in scheduling and executing construction activities, as the risk of accidents or injuries is reduced. Overall, the use of steel frame formwork in a construction project enhances its flexibility by providing adaptability, durability, accuracy, and safety. These factors enable construction teams to efficiently execute their tasks, make adjustments as needed, and ultimately deliver a successful and flexible construction project.

- Q: Can steel frame formwork be used for both interior and exterior staircase construction?

- Yes, steel frame formwork can be used for both interior and exterior staircase construction. Steel frame formwork provides a strong and durable structure that can withstand the weight and pressure of staircases, making it suitable for use in both indoor and outdoor settings.

- Q: Can steel frame formwork be used for both cast-in-place and precast concrete construction?

- Yes, steel frame formwork can be used for both cast-in-place and precast concrete construction. Steel frame formwork provides a versatile and durable solution that can be easily adjusted and reused for different construction projects. It ensures precise and accurate shaping of concrete elements, whether they are cast on-site or produced in a precast facility.

- Q: How does steel frame formwork compare to other types of formwork in terms of speed of construction?

- Steel frame formwork is known for its exceptional speed of construction when compared to other types of formwork. This is primarily due to its lightweight nature, ease of assembly, and high reusability. Unlike traditional timber formwork, which requires extensive cutting and shaping, steel frame formwork comes in pre-fabricated panels that can be quickly and easily assembled on-site. This significantly reduces the time and effort required for formwork installation. Additionally, steel frame formwork is designed to be easily adjustable and adaptable to different shapes and sizes, further enhancing its construction speed. Compared to other types of formwork, such as aluminum or plastic, steel frame formwork offers superior strength and durability. This allows for faster pouring and stripping of concrete, as the steel frame can withstand the pressure and weight of the concrete without distorting or collapsing. In contrast, other types of formwork may require additional time and effort for reinforcement or support, which can slow down the construction process. Furthermore, steel frame formwork is highly reusable, making it a cost-effective choice for projects with repetitive layouts or multiple casting cycles. The durability of steel ensures that it can withstand multiple uses, reducing the need for frequent replacements. This not only saves time and money but also contributes to a more sustainable construction process. In summary, steel frame formwork excels in terms of construction speed when compared to other types of formwork. Its lightweight, easy assembly, adaptability, and high reusability make it a preferred choice for projects that require efficient and rapid construction.

- Q: What are the different types of edge systems available for steel frame formwork?

- Steel frame formwork offers a variety of edge systems, each with its own advantages and applications. Let's take a look at some of the most common types: 1. L-shaped edge systems: These systems utilize L-shaped steel profiles that are affixed to the formwork panels. Their purpose is to provide a robust and steady edge against which the concrete can be poured, ensuring precise and straight edges. 2. Chamfer edge systems: If you're looking to create beveled edges on the concrete, chamfer edge systems are the way to go. They consist of steel profiles with angled surfaces that are attached to the formwork panels. Chamfer edges are frequently used for decorative and visually appealing finishes. 3. Curved edge systems: When you need curved or rounded concrete edges, curved edge systems are your best bet. These systems typically employ flexible steel profiles that can be easily bent or curved to achieve the desired shape. With curved edge systems, you can achieve smooth and seamless curved edges in the concrete. 4. Corner edge systems: Specifically designed for forming sharp corners in the concrete, corner edge systems feature steel profiles bent at a 90-degree angle to create the corner edge. These systems ensure well-defined and structurally sound concrete corners. 5. Adjustable edge systems: For projects that require flexibility in the formwork, adjustable edge systems come in handy. Typically consisting of modular components, these systems can be easily adjusted to accommodate different formwork configurations and dimensions. They are particularly useful for complex or irregularly shaped structures. Ultimately, the choice of edge system depends on the specific requirements of the construction project, including the desired finish, formwork complexity, and structural considerations.

- Q: What are the different types of lifting and handling equipment used with steel frame formwork?

- There are several types of lifting and handling equipment commonly used with steel frame formwork in construction projects. These equipment are designed to facilitate the movement, placement, and manipulation of the steel frames, making the assembly and disassembly process more efficient and less labor-intensive. 1. Cranes: Cranes are one of the most commonly used lifting equipment in construction. They are capable of lifting heavy loads and are often used to transport and position steel frame formwork components onto the construction site. They come in different sizes and types, such as tower cranes, mobile cranes, and crawler cranes, depending on the specific requirements of the project. 2. Forklifts: Forklifts are another widely used equipment for handling steel frame formwork. They are specifically designed for lifting and carrying heavy loads. Forklifts have forks that can be adjusted to accommodate the size and weight of the formwork components, allowing for precise placement and movement. 3. Hoists: Hoists are mechanical devices that are used to lift and lower loads vertically. They are commonly used for lifting smaller steel frame formwork components, such as beams and panels, to specific heights. Hoists are available in different configurations, including electric, manual, and air-powered, to cater to various project requirements. 4. Scaffolding: Scaffolding is a temporary structure that is used to support workers and materials during construction. It can also be used as a means of lifting and handling steel frame formwork components. Scaffolding systems often include pulleys and ropes that can be used to hoist and position the formwork components in place. 5. Jib Cranes: Jib cranes are smaller, more compact cranes that are typically mounted on walls or columns. They are commonly used in confined spaces or areas with limited access, where larger cranes cannot operate. Jib cranes are suitable for lifting and handling smaller steel frame formwork components with precision and ease. 6. Trolleys and Rollers: Trolleys and rollers are used to facilitate the movement of steel frame formwork components along the construction site. They can be used to transport and position the formwork components, allowing for smooth and efficient assembly or disassembly. Overall, the different types of lifting and handling equipment used with steel frame formwork provide construction workers with the necessary tools to safely and effectively manipulate and position the components. These equipment not only save time and effort but also ensure the smooth progress of the construction project.

- Q: Can steel frame formwork be used in combination with other formwork systems?

- Yes, steel frame formwork can be used in combination with other formwork systems. Steel frame formwork is a versatile and flexible system that can be easily adapted to different construction requirements. It can be used in conjunction with other formwork systems such as timber formwork, aluminum formwork, or modular formwork to achieve specific construction objectives. The combination of different formwork systems allows for more efficient and cost-effective construction processes. For example, steel frame formwork can be used for the main structural elements while timber formwork can be used for smaller components or irregular shapes. This combination can help optimize material usage and reduce costs. Moreover, using different formwork systems in combination can enhance the overall speed and productivity of the construction project. Each formwork system has its own advantages and limitations, and by combining them, contractors can leverage the benefits of multiple systems to achieve the best results. It is important, however, to ensure compatibility and proper coordination between the different formwork systems. The design and planning phase should take into consideration the integration of the various systems to ensure a seamless and efficient construction process. Close collaboration between the different trades involved in the construction project is crucial to ensure the successful combination of formwork systems. In conclusion, steel frame formwork can indeed be used in combination with other formwork systems. This flexibility allows for the optimization of construction processes, cost savings, and improved productivity. Proper coordination and collaboration are key to successfully integrating different formwork systems into a construction project.

- Q: What is the role of tie rods and connectors in steel frame formwork?

- Steel frame formwork systems rely heavily on tie rods and connectors, as these components are integral to their functionality. Their main purpose is to secure and stabilize the formwork panels, safeguarding the structure and ensuring its durability throughout the concrete pouring and curing processes. Tie rods are primarily responsible for preventing the formwork panels from bulging or collapsing under the immense pressure exerted by the concrete. Strategically positioned around the perimeter of the formwork system, these rods create a robust and inflexible framework. By connecting the outer and inner panels, they evenly distribute the load, minimizing the chances of deformation and ensuring a uniform concrete finish. Connectors, on the other hand, are specifically designed to secure the joints between the formwork panels. Their purpose is to create a tight seal that prevents any concrete leakage during pouring. Depending on the requirements and design of the formwork system, these connectors can take the form of clamps, pins, or bolts. Beyond their structural significance, tie rods and connectors also facilitate the assembly and disassembly of the formwork system. They allow for easy adjustment and alignment of the panels, guaranteeing precise and accurate formwork setup. This aspect is particularly crucial in achieving the desired shape, dimensions, and quality of the final concrete structure. To summarize, tie rods and connectors are indispensable components in steel frame formwork systems. They provide stability, strength, and adaptability, thus contributing to the safety, efficiency, and success of concrete construction projects.

- Q: Are there any special considerations when using steel frame formwork in seismic zones?

- Yes, there are several special considerations when using steel frame formwork in seismic zones. Firstly, the steel frame formwork system should be designed and constructed to be able to withstand the forces generated by seismic activity. This includes ensuring that the steel frames are adequately braced and reinforced to prevent collapse and maintain stability during an earthquake. Additionally, the connections between the steel frames should be carefully designed to allow for flexibility and movement, as well as to resist the lateral forces generated by seismic activity. This may include using specialized connectors or fasteners that can accommodate the dynamic loads imposed during an earthquake. Moreover, the formwork system should be properly anchored to the ground or structure to prevent displacement or failure during an earthquake. This may involve using specially designed anchor bolts or other means of secure attachment to ensure stability and safety. Furthermore, the selection of formwork materials should take into account the potential for damage or deformation during seismic events. Steel frames should be made of high-strength materials that can withstand the forces generated by earthquakes without experiencing significant distortion or failure. It is also important to consider the impact of seismic activity on the construction process itself. The timing and sequencing of formwork installation and removal should be carefully planned to minimize the risk of collapse or instability during an earthquake. Overall, the use of steel frame formwork in seismic zones requires careful consideration of design, construction, and material selection to ensure the safety and stability of the formwork system. Collaboration with structural engineers and adherence to building codes and regulations specific to seismic zones is crucial in order to mitigate the risks associated with seismic activity.

- Q: What are the cost implications of using steel frame formwork compared to other types of formwork?

- The cost implications of using steel frame formwork compared to other types of formwork can vary depending on several factors. Firstly, the initial cost of steel frame formwork tends to be higher than other types of formwork, such as timber or aluminum. Steel is a more expensive material, and the manufacturing process for steel frame formwork can be more complex. This initial higher cost may deter some builders or contractors from choosing steel frame formwork. However, steel frame formwork offers several advantages that can offset this initial cost. Steel is a highly durable material, which means that steel frame formwork can be reused multiple times, reducing the need for frequent replacements. This can result in long-term cost savings, as the lifespan of steel frame formwork can be significantly longer than other types of formwork. Additionally, steel frame formwork provides superior strength and stability compared to other materials. This allows for larger spans and higher pouring pressures, which can increase productivity and efficiency on construction sites. The ability to handle higher loads can also reduce the need for additional support structures, saving both time and money. Furthermore, steel frame formwork is known for its excellent dimensional accuracy and precision. This ensures that the final concrete structure meets the required specifications, reducing the need for rework and minimizing material wastage. This accuracy can also result in overall cost savings by improving construction timelines and reducing labor costs. Lastly, steel frame formwork offers the advantage of being easily adjustable and customizable. The modular design of steel formwork systems allows for easy assembly and disassembly, providing flexibility in creating various shapes and sizes of concrete structures. This adaptability can lead to increased efficiency and reduced construction time, ultimately impacting the overall cost of the project. In summary, while the initial cost of steel frame formwork may be higher compared to other types of formwork, the long-term benefits and cost savings it offers, such as durability, strength, precision, and flexibility, can outweigh these initial expenses. It is important for builders and contractors to carefully evaluate the specific requirements of their project and consider the potential cost implications before deciding on the type of formwork to use.

Send your message to us

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords