Sapa Aluminum Profiles for Shower Room OEM Aluminum Extrusion for High Voltage Switchgear

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

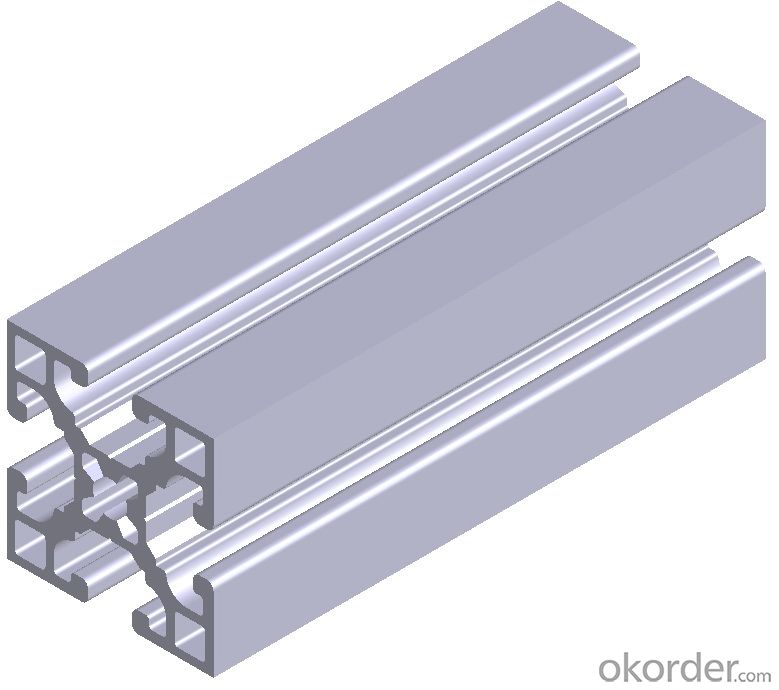

1.Structure of Shower Room OEM Aluminum Extrusion for high voltage Switchgear Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Shower Room OEM Aluminum Extrusion for high voltage Switchgear:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

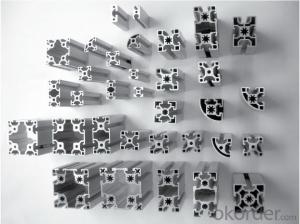

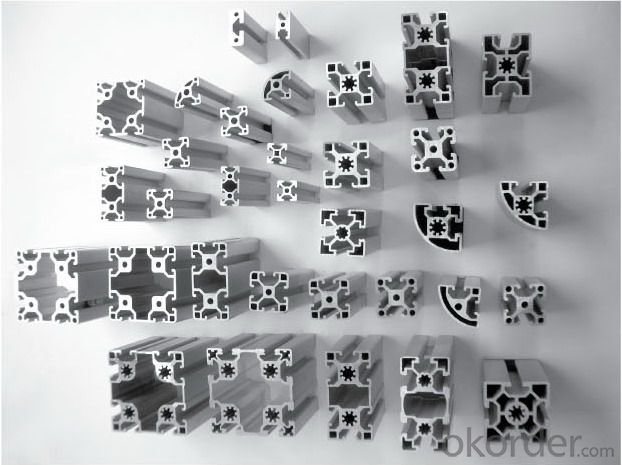

3.Shower Room OEM Aluminum Extrusion for high voltage Switchgear Images:

4.Aluminium Profile for Cars Auto-parts Good Quality Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the applications of aluminum profiles?

- Aluminum profiles have a wide range of applications in various industries due to their unique characteristics and properties. Some of the main applications of aluminum profiles include: 1. Construction: Aluminum profiles are extensively used in the construction industry for windows, doors, curtain walls, and structural components. They provide excellent strength, durability, and resistance to corrosion, making them ideal for building purposes. 2. Automotive: Aluminum profiles are used in the automotive industry for manufacturing lightweight and fuel-efficient vehicles. They are utilized in the production of car frames, engine mounts, heat exchangers, and other structural components. 3. Aerospace: Aluminum profiles find significant applications in the aerospace industry due to their high strength-to-weight ratio. They are used in the construction of aircraft frames, wings, fuselage, and other critical components. 4. Electrical and Electronics: Aluminum profiles are widely used in electrical and electronics applications. They are utilized in the manufacturing of heat sinks, LED lighting fixtures, electrical enclosures, and electronic device housings due to their excellent thermal conductivity and electrical insulation properties. 5. Furniture: Aluminum profiles are increasingly being used in the furniture industry for manufacturing lightweight and stylish furniture pieces. They are utilized in the production of chairs, tables, cabinets, and shelving systems, providing a modern and aesthetic appeal. 6. Industrial Machinery: Aluminum profiles are extensively used in the manufacturing of industrial machinery and equipment. They are utilized in the construction of conveyor systems, assembly line structures, machine frames, and guarding systems due to their lightweight, durability, and ease of fabrication. 7. Marine: Aluminum profiles are commonly used in the marine industry due to their corrosion resistance and lightweight properties. They are utilized in the construction of boat frames, masts, hulls, and other marine structures. 8. Renewable Energy: Aluminum profiles find applications in renewable energy systems such as solar panels and wind turbines. They are used in the manufacturing of solar panel frames, wind turbine supports, and mounting structures due to their lightweight and corrosion resistance. Overall, aluminum profiles offer a versatile and cost-effective solution for various industries, catering to their specific requirements for strength, durability, lightweight, and corrosion resistance.

- Q: Are aluminum profiles suitable for protective enclosures?

- Protective enclosures can be constructed using aluminum profiles, as they are lightweight, strong, and durable. This material is suitable for both indoor and outdoor applications due to its resistance to corrosion, UV rays, and extreme weather conditions. Moreover, aluminum profiles can be easily customized to meet specific enclosure requirements in terms of size, shape, and design. Additionally, the non-magnetic properties of aluminum are beneficial in applications where reducing magnetic interference is necessary. Thus, aluminum profiles offer a dependable and cost-effective solution for building protective enclosures in industries like electronics, telecommunications, automotive, and others.

- Q: This question asks for a method to determine the quantity of aluminum extrusions required for a particular project.

- <p>To calculate the amount of aluminum extrusions needed for a specific project, follow these steps: 1. Determine the dimensions and design of the project to understand where and how aluminum extrusions will be used. 2. Calculate the length of each extrusion piece required based on the project's structure. 3. Multiply the number of pieces by the length of each piece to get the total length of aluminum needed. 4. Consider any additional factors such as waste, tolerances, and potential design changes. 5. Consult with an aluminum supplier or use specialized software for more precise calculations, especially for complex projects. Always account for a margin of error and additional material for contingencies.</p>

- Q: Are there any specific safety precautions when working with aluminum profiles?

- Yes, there are specific safety precautions when working with aluminum profiles. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and hearing protection. It is also important to ensure proper ventilation in the workspace to prevent inhalation of aluminum dust or fumes. Additionally, precautions should be taken to avoid sharp edges and use proper lifting techniques to prevent injury.

- Q: What are the water-resistant properties of aluminum profiles?

- Aluminum profiles possess excellent water-resistant properties due to their inherent corrosion resistance. The aluminum surface forms a thin oxide layer that acts as a protective barrier against moisture and prevents water penetration. This makes aluminum profiles highly resistant to rust, rot, and degradation caused by water exposure, making them ideal for various applications in outdoor and wet environments.

- Q: What are the different assembly options available for aluminum profiles?

- Depending on specific requirements and applications, there are various assembly options available for aluminum profiles. Here are some commonly used methods: 1. For a strong and secure connection that allows frequent disassembly or adjustment, mechanical fastening is preferred. This involves using screws, bolts, or rivets to join aluminum profiles together. 2. When maximum strength and rigidity are needed, welding is an ideal choice. Aluminum profiles can be welded using techniques such as TIG or MIG welding, resulting in a seamless and strong joint. 3. Adhesive bonding is suitable for lightweight applications or when aesthetics are important. It provides a clean and seamless appearance without visible fasteners, although it may not be as strong as mechanical fastening or welding. 4. Aluminum profiles often have T-slot designs that allow the use of connecting elements like T-nuts, connectors, and brackets. These elements can be easily inserted into the slots and tightened to create a secure and adjustable joint, making it useful for flexible and easily reconfigurable applications. 5. Corner brackets are specifically designed to connect aluminum profiles at right angles. They can be easily attached using screws or bolts, providing a strong and rigid joint. They are commonly used in frame construction or for creating corners in structural applications. 6. Some aluminum profiles feature interlocking systems that eliminate the need for additional fasteners or connectors. These systems utilize specially designed shapes or grooves that fit together, ensuring a secure connection. They are often used in modular structures or systems that require quick assembly and disassembly. Ultimately, the choice of assembly method for aluminum profiles depends on factors such as strength requirements, aesthetics, ease of assembly, and the specific application or industry. Careful consideration of these factors is important when selecting the most suitable assembly option for a given project.

- Q: Where can I get it, or Jiaozhou, Jiaonan, where there are aluminium profiles? You'd better leave me a call... And do you have any training places for Thai engraving software?.

- What is the most portable electric bicycle brand, type, price, what store sale?It is produced in Beijing, Beijing Shenzhou giant new energy technology Co., Ltd., the factory mainly produces power type lithium batteries, with one of the smallest skillful bicycles, super lightweight, aluminum alloy body,The price is 3000 yuan, and the battery part is 1500 yuan. The battery is in the middle of the bicycle cross bar, and it is inside the cross bar. You can run 15 kilometers at a time, about 10 amperes per hour, and 24 volts. The front wheel drive motor mounted on the front fork, the front wheel of the plastic rim with inner teeth, and the gear motor.Shenzhen ZOOM Ruimu, Shenzhen Xinlong Health Industry Development Co. Ltd (Shenzhen City, Baoan District Longhua Street Longfa Road No. 11, shop: Shenzhen Nanshan District City Nanhai Road Oncidium Road No. 35, 0755-83131635 83131272) but also the production of small electric bicycle is similar to that of the aluminum alloy body, lithium batteries of the same size, the difference is the rear wheel hub motor, 2880 yuan / vehicles, he said after charging can run 40 kilometers, I feel is that big. Design, scooters and electric vehicles structure, technology and engineering, the difficulty of safety is different, can not be confused together, here is their distinction;

- Q: Which is the highest price of aluminum profile 60616063?

- 6063 general construction profiles, that is industrial profiles

- Q: Is it possible to manufacture aluminum profiles in unique shapes or dimensions tailored for particular uses?

- <p>Yes, aluminum profiles can be made into custom shapes or sizes for specific applications. Manufacturers can customize aluminum profiles through various processes such as extrusion, cutting, bending, and machining to meet the unique requirements of different projects. This flexibility allows for the creation of specialized components that can be used in a wide range of industries, including construction, automotive, aerospace, and more.</p>

- Q: Are aluminum profiles recyclable?

- Yes, aluminum profiles are recyclable. Aluminum is a highly recyclable material, meaning it can be melted down and reused multiple times without losing its quality. Aluminum profiles, which are used in various applications such as construction, transportation, and manufacturing, can be easily recycled by collecting them from end-of-life products or scrap material and sending them to a recycling facility. The recycling process involves shredding the aluminum profiles into small pieces, removing any impurities, melting the aluminum, and then casting it into new profiles or other aluminum products. Recycling aluminum profiles helps to conserve natural resources, reduce energy consumption, and minimize environmental impact compared to producing new aluminum from raw materials.

Send your message to us

Sapa Aluminum Profiles for Shower Room OEM Aluminum Extrusion for High Voltage Switchgear

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords