Camouflage Sandwich Panel and Sheet Aluminum Coil Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

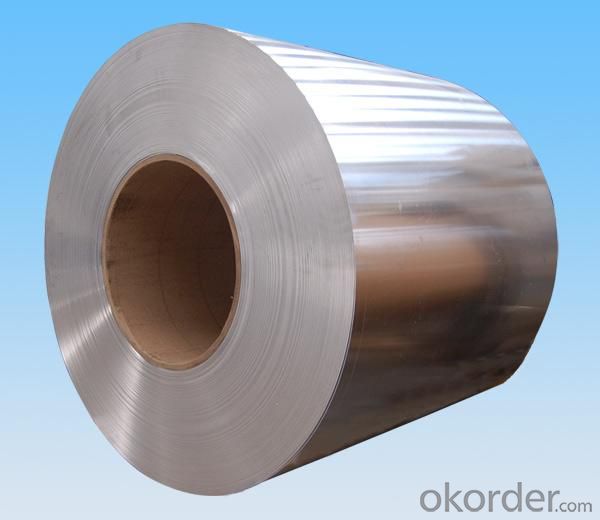

Sandwich Panel and sheet Aluminum Coil Material

Hot-rolled High Quality Low Price Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

Temper: O, F, HXX

Thickness: Thickness

Width: 1000-1500mm

Type: Coil/Roll

Surface Treatment: mill finished

Application: Decoration, packaging, printing, covering

Standard size: Upon customer's demand

Quantity: 18tons(±10%)in one 20 feet container

Hot Rolled Aluminium coil | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050,1060,1070, | O,F, H12, 114,H18,H22, H24,H26,H32, H34,H36,H111, | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

Packaging detail: First, plastic cloth; Second, Pearl Wool ; Third, wooden cases with dry agent ,without fumigation, wooden pallets

Delivery detail: Within 25days

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: Is it possible to recycle aluminum sheets multiple times?

- <p>Yes, aluminum sheets can be recycled again and again. The recycling process for aluminum is highly efficient, and it can be recycled indefinitely without losing any quality. This is due to the fact that aluminum retains its properties even after multiple recycling cycles. Each time aluminum is recycled, it can be melted down and reformed into new products, making it a sustainable and environmentally friendly material.</p>

- Q: Can someone please help me with the resonance structure for AlCl3. When I draw it, the central Al does not have a complete octet. I read that this is usually the case for atoms like Boron and Aluminium who only have three valence electrons. Is this correct? Also, as a follow on question, does AlCl3 display resonance?

- Since aluminum only has 3 valence electrons it will be missing two electrons from its octet. This means that one of the chloride groups must share an extra electron group with the aluminum. Any three of the chlorides can share an extra electron pair with it (i.e. they'll have 2 lines attached to aluminum), so there is resonance. There are 3 to be specific, one for each chloride sharing another electron pair with Al.

- Q: Are aluminum sheets corrosion-resistant?

- Aluminum sheets possess corrosion-resistant properties. The presence of a natural oxide layer on the surface of aluminum serves as a protective shield against corrosion. This oxide layer is exceptionally stable and effectively hinders further oxidation. Moreover, aluminum does not react with various corrosive substances like saltwater, acids, and alkalis. Nevertheless, there are certain situations or environments where aluminum remains susceptible to corrosion. For instance, in highly acidic or alkaline settings, aluminum may corrode more rapidly. Hence, it is crucial to carefully evaluate the application and environment to guarantee ideal corrosion resistance when utilizing aluminum sheets.

- Q: Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Certainly! Electronic heat sinks can be manufactured using aluminum sheets. Due to its outstanding thermal conductivity and lightweight characteristics, aluminum has become a favored material for heat sinks. It facilitates the efficient dissipation and regulation of heat produced by electronic components. By easily molding and shaping aluminum sheets, the desired heat sink design can be achieved, thereby ensuring effective cooling for electronic devices.

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is approximately 0.000022 per degree Celsius. This means that for every degree Celsius increase in temperature, the aluminum sheet will expand by 0.000022 times its original length. This coefficient of expansion is important to consider in applications where the aluminum sheets may be exposed to varying temperatures, as it can affect the overall dimensions and stability of the material.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: Are aluminum sheets suitable for insulation purposes?

- Yes, aluminum sheets are suitable for insulation purposes. Aluminum is a good conductor of heat, so it can effectively reflect and block thermal energy. Additionally, aluminum sheets are lightweight, corrosion-resistant, and easy to install, making them a popular choice for insulation applications.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- Yes, 101 aluminum sheets are suitable for medical equipment.

Send your message to us

Camouflage Sandwich Panel and Sheet Aluminum Coil Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 360 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords