Rusted Stainless Steel Sheets 201 Low Price Tisco Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

stainless steel sheet

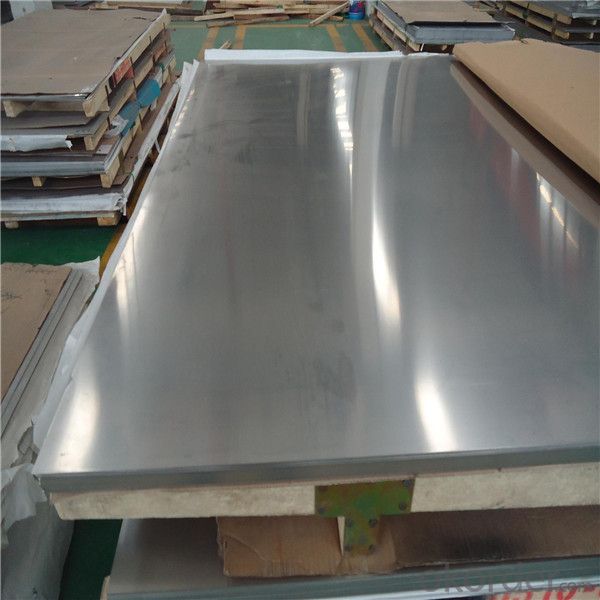

1.Thickness:0.1-150mm

2.Width:500-3000mm

3.Length:500-6000mm

4.BV ISO ROHS SGS

Stainless steel sheet

Item | Stainless steel sheet |

Description | Stainless steel sheet,stainless steel plate,cold rolled stainless steel sheet,hot rolled stainless steel sheet,stainless checkered sheet, stainless steel decorative sheet |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,BS,GB |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H, 409,409L,410,420,430 |

Finish(Surface) | NO.1, NO.2D, NO.2B, BA,NO.3, NO.4,NO.240,NO.400,Hairline,NO.8, Brushed |

Exported Area | USA,UAE,Europe,Asia,Middle East,Africa,South America |

Thickness | Form 0.4mm to 100mm |

Width | 1000mm,1219mm(4feet),1250mm,1500mm,1524mm(5feet),1800mm,2200mm or we can also help the size as you require |

Length | 2000mm,2440mm(8feet),2500mm,3000mm,3048mm(10feet),5800mm, 6000mm or we can make the length as you require |

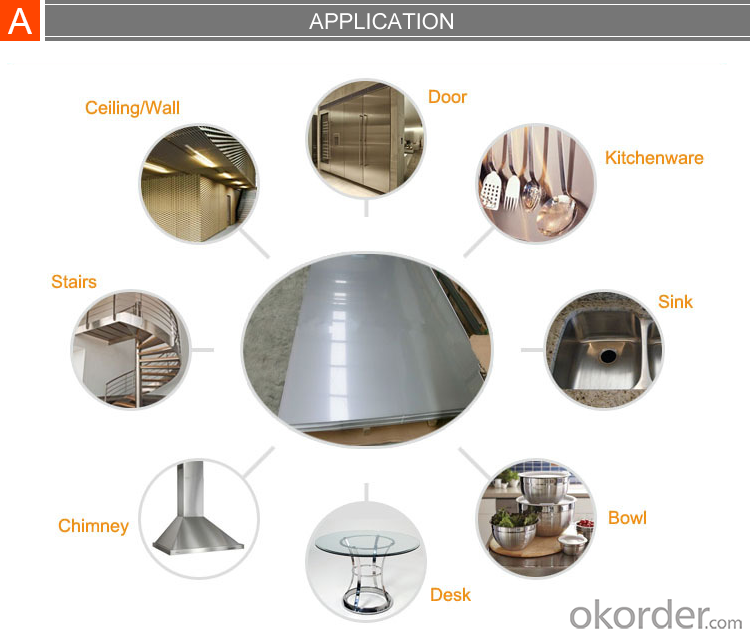

Application | Stainless steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heatexchanger, machinery and hardware fields. Stainless steel sheet can be made accordingto the customers requirements. Fast delivery. Quality assured.Welcome to order more. |

Package Detail | Standard seaworthy package(wooden boxes package,pvc package, and other package) |

Delivery Time | According to your size and quantity or as customers require |

Payment Term | T/T ,L/C |

Advantage | Good quality with reasonable price |

THE CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES

| Grade | C (Max) | Mn (Max) | P (Max) | S (Max) | Si (Max) | Cr | Ni | Mo | Nitrogen (Max) | Cu/ Others |

| 201 | 0.15 | 5.50-7.50 | 0.06 | 0.03 | 1 | 16.00-18.00 | 3.50-5.50 | - | 0.25 | |

| 202 | 0.15 | 7.50-10.00 | 0.06 | 0.03 | 1 | 17.00-19.00 | 4.00-6.00 | - | 0.25 | |

| 301 | 0.15 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 6.00 - 8.00 | - | 0.1 | - |

| 304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.00 - 20.00 | 8.00- 10.50 | - | 0.1 | - |

| 304L | 0.03 | 2 | 0.045 | 0.03 | 1 | 18.00 - 20.00 | 8.00- 12.00 | - | 0.1 | - |

| 310S | 0.08 | 2 | 0.045 | 0.03 | 1.5 | 24.00- 26.00 | 19.00-22.00 | - | - | - |

| 316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | - |

| 316L | 0.03 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | - |

| 316Ti | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.00 - 18.00 | 10.00- 14.00 | 2.00 - 3.00 | 0.1 | Ti5x C Min |

| 317 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 18.00 - 20.00 | 11.00 - 14.00 | 3.00 - 4.00 | 0.1 | - |

| 317L | 0.03 | 2 | 0.045 | 0.03 | 0.75 | 18.00 - 20.00 | 11.00 - 15.00 | 3.00 - 4.00 | 0.1 | - |

| 321 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 17.00 - 19.00 | 9.00 - 12.00 | - | 0.1 | Ti5xC Min |

| 347 | 0.08 | 2 | 0.045 | 0.03 | 0.75 | 17.00 - 19.00 | 9.00 - 13.00 | - |

- Q:Can stainless steel sheets be used in industrial applications?

- Yes, stainless steel sheets can be used in industrial applications. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various industrial sectors such as construction, automotive, manufacturing, and food processing. It is commonly used for building structures, machinery components, storage tanks, and in environments that require high hygiene standards.

- Q:What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

- Q:Which is better, stainless steel plate kitchen?

- According to the organizational structure of classification at room temperature, a martensitic, Austenitic, Ferritic and duplex stainless steel; according to the classification of the main chemical components, basically can be divided into chromium and chromium nickel stainless steel two systems; by use of minute nitric acid resistant stainless steel, stainless steel, stainless steel corrosion resistance to sulfuric acid and so on, according to the corrosion resistance the type can be divided into stainless steel pitting corrosion, stress corrosion resistant stainless steel, intergranular corrosion resistant stainless steel etc.;

- Q:Are stainless steel sheets suitable for elevator doors?

- Stainless steel sheets make for suitable elevator doors. They are a popular pick for this purpose because they are durable, resistant to corrosion, and aesthetically pleasing. Elevator doors endure constant use and exposure to various elements, which is why stainless steel is an ideal material. It doesn't easily rust or corrode. Furthermore, stainless steel sheets are easy to maintain and clean, ensuring a long-lasting and visually appealing appearance. The versatility of stainless steel also allows for customization in terms of finishes, textures, and patterns, which means elevator doors can be designed to match the desired aesthetic of the building or space. In summary, stainless steel sheets are a reliable and fitting option for elevator doors.

- Q:How do you determine the thickness of stainless steel sheets required for a specific application?

- To determine the thickness of stainless steel sheets required for a specific application, several factors need to be considered. 1. Load-bearing capacity: The first step is to determine the maximum load the stainless steel sheets will need to support. This can be calculated by considering the weight of the objects or materials that will be placed on the sheets. It is important to account for any potential dynamic loads or impact forces that may be applied. 2. Deflection limits: Deflection refers to the amount of bending or sagging that occurs when a load is applied to the stainless steel sheets. The deflection limits will depend on the specific application and the desired performance of the sheets. In general, minimizing deflection is crucial for structural integrity and to ensure the stainless steel sheets can handle the intended load without excessive bending. 3. Material properties: Stainless steel sheets come in different grades, each with its own mechanical properties. The tensile strength, yield strength, and hardness of the stainless steel should be considered to ensure it can withstand the required load and any potential environmental conditions such as corrosion or extreme temperatures. 4. Safety factors: It is important to apply appropriate safety factors to ensure the stainless steel sheets have a margin of safety. Safety factors account for uncertainties in load calculations, material properties, and other factors. The safety factor can vary depending on the level of confidence required, but it is typically recommended to apply a safety factor of at least 1.5 to 2. 5. Industry standards and regulations: Depending on the specific application, there may be industry standards or regulations that dictate the minimum thickness requirements for stainless steel sheets. It is important to consult these standards and ensure compliance to ensure the sheets meet any safety or performance requirements. By considering these factors and performing engineering calculations, it is possible to determine the appropriate thickness of stainless steel sheets required for a specific application. It is always recommended to consult with an experienced engineer or stainless steel supplier to ensure accurate calculations and to account for any specific requirements or considerations unique to the application.

- Q:Are stainless steel sheets suitable for elevator wall panels?

- Indeed, elevator wall panels can be made from stainless steel sheets. The use of stainless steel is quite popular for such panels due to its strong and enduring nature, as well as its ability to resist corrosion. Given that elevators are areas with high foot traffic, it is crucial to select a material that can withstand constant usage and potential impact. Stainless steel sheets are resilient and can endure the wear and tear associated with elevator usage. Moreover, stainless steel possesses a remarkable resistance to corrosion, making it a suitable choice for environments that experience high humidity or exposure to chemicals. Furthermore, stainless steel adds a sleek and contemporary touch to the interior of elevators, enhancing their elegance. Overall, stainless steel sheets are a dependable and visually pleasing option for elevator wall panels.

- Q:What are the features of stainless steel plates?

- Can withstand oxalic acid, sulfuric acid iron sulfate, nitrate, nitrate acid and hydrofluoric acid, sulfuric acid copper sulfate, phosphoric acid, formic acid and acetic acid and various acid corrosion, widely used in chemical, food, medicine, papermaking, petroleum, atomic energy industry, as well as construction, kitchen utensils, cutlery, household appliances, vehicles of all kinds of parts.

- Q:Are stainless steel sheets suitable for kitchen countertops?

- Kitchen countertops made from stainless steel sheets are highly suitable. They have numerous benefits that make them a popular choice. Firstly, stainless steel is incredibly durable and can withstand stains, heat, and scratches. This makes it perfect for the kitchen, where spills, hot pans, and knife marks are common. Moreover, stainless steel is non-porous, meaning it doesn't harbor bacteria or germs. This makes it an excellent choice for food preparation areas, as it ensures hygiene. Cleaning and maintaining stainless steel is also a breeze, as it doesn't require any special products or sealants. A simple wipe with a damp cloth is usually sufficient to keep it looking shiny and new. Additionally, stainless steel has a sleek and modern appearance that complements various kitchen styles and designs. It can be paired with different cabinetry colors and materials, creating a timeless and contemporary look. Stainless steel is also versatile, as it can be custom fabricated to fit any kitchen layout, including seamless integration with sinks and backsplashes. Lastly, stainless steel is an environmentally friendly option. It is a recyclable material, and many stainless steel products are made from recycled steel. This makes it a sustainable choice for those who want to minimize their environmental impact. In conclusion, stainless steel sheets are an excellent option for kitchen countertops due to their durability, resistance to stains and scratches, hygienic properties, easy maintenance, sleek appearance, and environmental friendliness.

- Q:How do you remove fingerprints from stainless steel sheets?

- To remove fingerprints from stainless steel sheets, you can start by using a microfiber cloth or a soft cloth dampened with warm water and mild dish soap to gently wipe the surface. Then, rinse the cloth and wipe away any soap residue. If the fingerprints persist, you can try using a mixture of vinegar and water or rubbing alcohol on the cloth to further clean the stainless steel. Finally, make sure to dry the sheets thoroughly with a clean cloth to prevent water spots.

- Q:What is the minimum order quantity for stainless steel sheets?

- The minimum order quantity for stainless steel sheets may differ based on the supplier and the specific product. Nevertheless, it is typical for suppliers to impose a minimum order quantity between 1 and 10 sheets. To select the most suitable option for your requirements, it is crucial to reach out to multiple suppliers and inquire about their minimum order requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rusted Stainless Steel Sheets 201 Low Price Tisco Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords