Civil Works Material HDPE Geosynthetic Clay Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Civil Works Material HDPE Geosynthetic Clay Liner(GCL)

1,Introduction

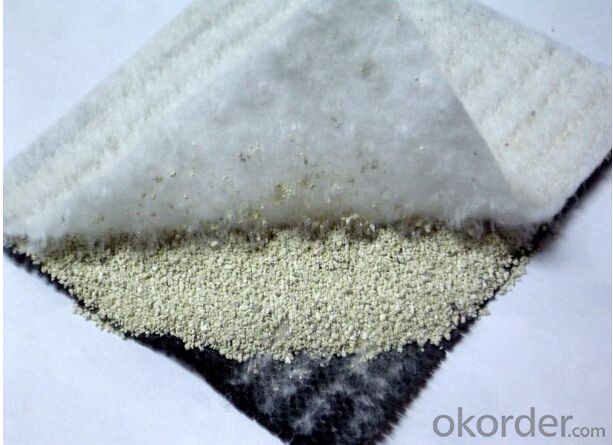

Our GCL is composed of 3 layers, the upper layer is nonwoven geotextile, while the lower layer is woven geotextile, natural sodium bentonite fills the gap between geotextile layers. The application with natural sodium bentonite can enlong the using life of construction. Our GCL creates a new green and environmental building material.

We have two kinds of GCL. One is GCL without HDPE layer, the other is HDPE GCL. For GCL, it is widely used in landfill, lagoon, river bottom, basement and so on. For HDPE GCL, it is used in subway, basement, tunnel, underground and projects, salt water area in harsh environment.

2,Features

1. Environment friendly

Our GCL is made of natural sodium bentonite, which contributes to good water proof quality, while causes no pollution to the environment. Its porosity guarantees the breath of biology.

2. Long-lasting waterproof performance

Natural sodium bentonite was formed billions of years ago. Its waterproof performance can last longer than building itself.

3. Easy application

Application of GCL is not constrained by weather. Connection and restore is easy to be finished.

3,Application

· Landfills | · Mud Pits |

· Lagoons | · Canals |

· Bund Lining | · Tank Lining |

· Fish Farm Lining | · Roof Lining |

· Waste Water Pits | · Ponds and Reservoirs |

· Dams | · Floating Covers |

· Vertical Cutoff Walls | · Hydraulic Structure |

· Basement Lining | · Drip Irrigation Ponds |

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

Can you provide free samples?

Yes, our samples are always free, but express fees ususlly on buyer's account.

- Q: What are the advantages of using gabion walls?

- There are several advantages of using gabion walls. Firstly, they are highly durable and can withstand various environmental conditions, including heavy rainfall and erosion. Secondly, gabion walls are flexible and can easily adapt to the natural terrain, making them suitable for uneven surfaces. Additionally, they provide excellent drainage, preventing water buildup and reducing the risk of flooding. Moreover, gabion walls are cost-effective compared to traditional concrete or brick walls, as they require less maintenance and can be constructed using locally available materials. Lastly, these walls are eco-friendly, as they allow for vegetation growth and support wildlife habitats.

- Q: What are the main properties of the materials used in civil engineering requirements?

- Environmental protection, economy, convenience are in line with the job

- Q: How do geosynthetic products contribute to erosion control in coastal areas?

- Geosynthetic products play a crucial role in erosion control in coastal areas by providing effective solutions to stabilize and protect the shoreline. These products, such as geotextiles, geogrids, and geocells, are designed to enhance the natural resilience of coastal ecosystems while preventing land loss due to erosion. They are used in various applications like beach nourishment, dune stabilization, revetments, and breakwaters. By providing additional structural support, geosynthetics help to dissipate wave energy, reduce sediment transport, and promote sediment accretion. Overall, geosynthetic products are instrumental in maintaining the integrity of coastal areas and safeguarding them from erosion.

- Q: Can geosynthetics be used for lining fish ponds?

- Yes, geosynthetics can be used for lining fish ponds. They are commonly used as liners to prevent water seepage and create a barrier between the pond and the ground. Geosynthetics offer various benefits such as durability, flexibility, and resistance to chemicals, making them suitable for lining fish ponds and ensuring the containment of water and the protection of fish habitats.

- Q: What are the advantages of using earthwork products in construction?

- There are several advantages of using earthwork products in construction. Firstly, these products are typically cost-effective compared to other construction materials, making them a budget-friendly option. Additionally, earthwork products are often readily available in abundance, making them easily accessible for construction projects. They also offer excellent thermal insulation properties, helping to regulate the temperature inside buildings and reducing energy consumption. Moreover, earthwork products are highly durable and have a long lifespan, ensuring the longevity of the constructed structures. Lastly, using earthwork products is an environmentally friendly choice as they are natural materials that do not harm the ecosystem or contribute to pollution.

- Q: Can earthwork products be used for rainwater harvesting?

- Yes, earthwork products can be used for rainwater harvesting. Earthworks, such as berms, swales, and ponds, can effectively capture and store rainwater, allowing it to infiltrate into the soil or be stored for later use. These earthwork features can help prevent erosion, recharge groundwater, and provide a sustainable source of water for various purposes, including irrigation and household use.

- Q: How are geotextile tubes used in sediment control during harbor dredging?

- Geotextile tubes are commonly used in sediment control during harbor dredging by acting as containment structures for the dredged material. They are filled with the dredged sediment and then positioned strategically to create temporary dikes or barriers, preventing the sediments from dispersing into the surrounding water. The tubes' permeable fabric allows water to exit while retaining the sediment, effectively controlling erosion and maintaining water quality during the dredging process.

- Q: What are the common applications of earthwork products?

- Common applications of earthwork products include construction projects such as building foundations, roads, dams, and landscaping projects. These products are used to provide stability, support, and shaping of the earth's surface to create a desired structure or landscape.

- Q: How do geosynthetic products contribute to soil erosion prevention in recreational areas?

- Geosynthetic products, such as geotextiles and geogrids, play a crucial role in preventing soil erosion in recreational areas. These products are designed to provide reinforcement and stabilization to the soil, preventing it from being washed away by water or wind. They are commonly used in the construction of retaining walls, slope stabilization, and erosion control measures like terracing. By effectively containing the soil and reinforcing its structure, geosynthetic products minimize soil erosion and ensure the longevity and safety of recreational areas.

- Q: What are the different types of geosynthetic tubes used in riverbank protection?

- There are several types of geosynthetic tubes used in riverbank protection, including geotextile tubes, geogrid tubes, and geocell tubes. Geotextile tubes are made of high-strength woven or non-woven geotextile fabric and are filled with sand or soil to provide erosion control and stabilize riverbanks. Geogrid tubes, on the other hand, are constructed using geogrid materials and are typically filled with aggregate or other materials to reinforce the riverbank. Geocell tubes consist of interconnected cells made of geosynthetic materials and are filled with soil or other materials to create a porous structure that prevents erosion and promotes vegetation growth. These different types of geosynthetic tubes offer various solutions for riverbank protection depending on the specific needs and conditions of the site.

Send your message to us

Civil Works Material HDPE Geosynthetic Clay Liner

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords