Ring-lock Scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

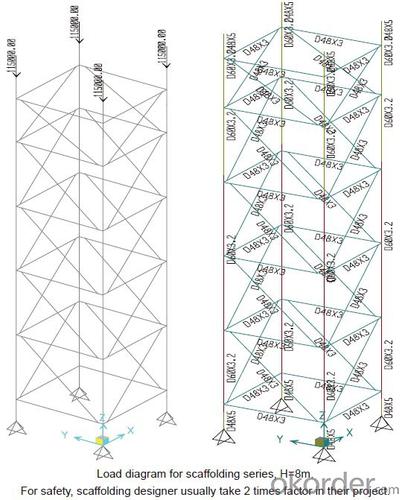

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Can steel formwork be used for curved or complex shapes?

- Indeed, curved or complex shapes can be achieved using steel formwork. Steel, being a resilient and long-lasting material, can effortlessly be manipulated and molded to accommodate diverse designs. Its flexibility allows for the creation of intricate and personalized formwork systems suitable for a vast array of applications, including curved or complex shapes. The robustness and solidity of steel guarantee that the formwork remains steadfast throughout the pouring and setting of concrete, enabling meticulous and precise construction. Furthermore, the reusability of steel formwork proves to be an economical choice for projects necessitating curved or complex shapes.

- Q: What are the main components of a steel formwork system?

- The main components of a steel formwork system typically include panels, connectors, clamps, pins, and wedges.

- Q: How does steel formwork handle concrete surface blemishes?

- Steel formwork is a popular choice for construction projects due to its durability and strength. When it comes to handling concrete surface blemishes, steel formwork offers several advantages. Firstly, the smooth and rigid surface of steel formwork helps minimize the occurrence of surface blemishes on the concrete. Unlike other formwork materials such as timber, steel does not warp or deform easily, ensuring a consistent and even surface for the concrete to be poured onto. This reduces the chances of surface imperfections like air pockets, formwork marks, or uneven textures. Moreover, steel formwork allows for precise control over the concrete pouring process. The steel panels are manufactured with high precision, ensuring accurate dimensions and alignment. This precision, coupled with the tight joints and connections between the panels, minimizes the likelihood of concrete seepage or leakage, which can lead to surface blemishes such as honeycombing or efflorescence. Additionally, steel formwork can be easily cleaned and maintained, which further contributes to preventing or handling concrete surface blemishes. The smooth surface of steel allows for easy removal of any excess concrete or debris that might accumulate during the pouring process. This prevents the formation of unwanted blemishes and preserves the quality of the concrete surface. In cases where concrete surface blemishes do occur, steel formwork offers the advantage of being reusable. Unlike other formwork materials that may need to be discarded after a single use, steel formwork can be easily cleaned, repaired, and reused for multiple projects. This allows for more control over the quality of the formwork, reducing the risk of surface blemishes in subsequent concrete pours. In conclusion, steel formwork handles concrete surface blemishes effectively by providing a smooth and rigid surface, precise control over the pouring process, easy maintenance and cleaning, and reusability. These features contribute to achieving a high-quality concrete surface with minimal blemishes, ensuring a visually appealing and structurally sound end result.

- Q: Can steel formwork be used in retail or commercial construction projects?

- Retail or commercial construction projects can benefit greatly from the use of steel formwork. This versatile and durable solution is ideal for creating concrete structures, offering numerous advantages. With its high reusability, excellent dimensional stability, and ability to handle high concrete pressures, steel formwork is a reliable choice. In these types of projects, steel formwork can be utilized for various applications including columns, walls, beams, slabs, and staircases. It provides a strong framework, ensuring accurate and smooth concrete placement, resulting in top-notch finishes. Moreover, steel formwork can be easily customized and adjusted to meet different project requirements, making it suitable for complex architectural designs. In addition to its flexibility, steel formwork also brings significant time and cost savings to construction projects. Its reusability minimizes the need for frequent formwork replacements, leading to reduced material and labor costs. The use of steel formwork further enhances construction efficiency by allowing for quick assembly, disassembly, and repositioning of formwork components. Overall, steel formwork is a dependable and efficient choice for retail or commercial construction projects, providing the necessary strength and flexibility for such applications.

- Q: Can steel formwork be used for both simple and complex architectural designs?

- Steel formwork is a versatile option that can be used for both simple and complex architectural designs. It can be shaped and customized to different sizes and shapes, making it suitable for a variety of projects. Its flexibility allows for the creation of intricate and unique forms. In addition, steel formwork offers excellent strength and stability, enabling it to withstand the pressures and forces exerted during the concrete pouring process. This makes it an ideal choice for constructing structures with complex shapes and designs. Moreover, steel formwork is durable and can be reused, making it a cost-effective solution for projects involving both simple and complex architectural designs. Overall, steel formwork is a reliable and efficient option that can be used in a wide range of architectural designs, regardless of their complexity.

- Q: Are there any limitations or disadvantages of using steel formwork?

- There exist certain limitations and drawbacks associated with the utilization of steel formwork. One constraint pertains to the cost. Comparatively, steel formwork tends to be more expensive in comparison to alternative formwork types, such as wood or aluminum. Consequently, it may not be a practical choice for projects operating within tight budgetary constraints. Another limitation involves the weight and unwieldiness of steel formwork. Its substantial weight makes transportation and handling challenging, potentially necessitating additional equipment and labor. Moreover, the bulkiness can complicate the storage and stacking of the formwork when not in use. The assembly and disassembly of steel formwork also require skilled labor. Unlike certain formwork types like modular or reusable plastic formwork, steel formwork often necessitates custom-made fittings at the construction site. This can lead to increased labor costs and elongated construction timelines. Additionally, without proper maintenance, steel formwork is susceptible to corrosion. Exposing it to moisture, chemicals, and harsh weather conditions can result in rusting, thereby weakening the formwork over time. Regular inspections and maintenance are indispensable for ensuring the longevity and safety of steel formwork. Lastly, depending on the nature of the construction project, steel formwork may not be suitable. Its rigidity and lack of flexibility make it less adaptable to complex or irregular shapes. Consequently, alternative formwork materials or systems may prove more suitable in such instances. Despite these limitations and disadvantages, steel formwork also presents several advantages, including durability, reusability, and a high load-bearing capacity. Consequently, it is crucial to thoughtfully consider the project's specific requirements prior to making a decision on whether to employ steel formwork.

- Q: Can steel formwork be used for precast concrete beams with complex geometries?

- Precast concrete beams with intricate geometries can indeed utilize steel formwork. The utilization of steel formwork presents various advantages in the creation of complex shapes and designs in precast concrete beams. Thanks to its robust and long-lasting nature, steel can withstand the immense pressures and forces exerted during the pouring and curing process of concrete. It can be conveniently fabricated to achieve the desired shape and size of the beam, rendering it suitable for complex geometries. Moreover, steel formwork guarantees excellent dimensional accuracy, ensuring that the precast concrete beams maintain their intended shape and dimensions. This aspect becomes particularly crucial for beams with intricate geometries, as even slight variations in shape may jeopardize their structural integrity. Additionally, steel formwork grants a smooth and high-quality finish to the concrete surface. For beams with complex geometries, this smooth surface becomes indispensable, as it ensures proper load distribution and mitigates the risk of cracking or other structural issues. Furthermore, steel formwork can be reused multiple times, making it a cost-effective choice for the creation of precast concrete beams with intricate geometries. The versatility and durability of steel formwork position it as the preferred option for various construction projects, particularly those involving complex precast concrete beams. In conclusion, steel formwork proves to be a suitable and practical alternative for fashioning precast concrete beams with complex geometries. Its strength, durability, dimensional accuracy, and smooth finish make it an ideal solution for achieving the desired shape and design in these beams.

- Q: Can steel formwork be used for both residential and industrial construction projects?

- Yes, steel formwork can be used for both residential and industrial construction projects. Steel formwork is highly versatile and can withstand heavy loads, making it suitable for various construction applications. Its durability and strength make it ideal for use in both residential and industrial settings.

- Q: What are the different types of formwork bracing used in steel formwork?

- In steel formwork, there are various types of formwork bracing, each with its own unique features and benefits. Here are some of the most commonly used types: 1. Adjustable Steel Bracing: This bracing consists of adjustable steel tubes or rods that can be extended or retracted easily to the desired length. It allows for quick and easy installation and adjustment, making it ideal for projects with varying formwork heights. 2. Cross Bracing: Cross bracing involves diagonal steel members placed to create an "X" shape between vertical supports. It provides lateral stability to the formwork system and helps prevent buckling or deformation. 3. Tie Rod Bracing: Tie rod bracing uses threaded steel rods connected through formwork panels to provide extra strength and stability. It is commonly used in large-scale formwork systems that need to support high loads. 4. External Bracing: To increase stability against wind forces, taller formwork structures often use external bracing. Steel members are installed on the exterior side of the formwork system to resist lateral movement and maintain structural integrity. 5. Kickers: Kickers are diagonal bracing elements installed between formwork panels and the ground or a solid anchor point. They transfer lateral forces and prevent the formwork from tilting or collapsing. 6. Strut Bracing: Strut bracing involves placing steel struts or props vertically between the formwork panels and the ground. It provides additional support to prevent horizontal movement and ensure the stability of the formwork system. 7. Flying Bracing: When formwork needs support from above, such as in bridge construction or overhead structures, flying bracing is used. Bracing elements are suspended from overhead supports to provide stability and prevent formwork deformation. Each type of formwork bracing offers advantages and is chosen based on specific project requirements, including formwork height and size, expected loads, and site conditions. A combination of different bracing types may also be used to ensure optimal stability and safety.

- Q: Can steel formwork be used for architectural concrete beams?

- Yes, steel formwork can be used for architectural concrete beams. Steel formwork offers high strength and durability, making it suitable for supporting the weight and shape of architectural concrete beams during the casting process. It provides a smooth and uniform finish, ensuring precise and accurate results in terms of shape and dimensions. Additionally, steel formwork is reusable, which makes it cost-effective and environmentally friendly for architectural concrete beam construction.

Send your message to us

Ring-lock Scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords