Ring-Lock Scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

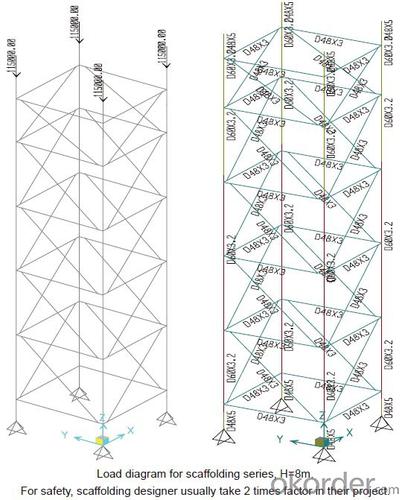

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Can steel formwork be used for both residential and commercial renovations?

- Indeed, both residential and commercial renovations can make use of steel formwork. Renowned for its durability and strength, steel formwork proves itself suitable for diverse construction endeavors. Whether it involves a residential renovation, such as extending a property, or a commercial renovation, like refurbishing an office space, steel formwork delivers the required support and stability throughout the construction phase. Moreover, steel formwork readily lends itself to customization and adjustment to meet various project specifications, rendering it a versatile choice for both residential and commercial renovations.

- Q: How does steel formwork prevent concrete leakage?

- Steel formwork prevents concrete leakage by providing a strong and rigid structure that holds the concrete in place during the pouring and curing process. The steel panels are tightly connected and sealed to form a watertight barrier, preventing any leakage or seepage of the concrete.

- Q: How does steel formwork prevent concrete honeycombing?

- To prevent concrete honeycombing, steel formwork is employed as it serves as a robust and rigid structure that securely holds the concrete in place during pouring and curing. The presence of voids or gaps in the concrete mixture can result in honeycombing, which compromises both the structural integrity and aesthetic appeal of the final product. The design of steel formwork ensures its durability and resilience, guaranteeing that it maintains its shape and prevents any movement or displacement of the concrete. This effectively reduces the likelihood of air pockets or voids forming within the concrete mixture, thus mitigating the occurrence of honeycombing. Moreover, steel formwork is typically constructed with smooth surfaces that prevent the concrete from adhering to the formwork. Consequently, the removal of the formwork after the concrete has cured becomes easier, minimizing the risk of any damage or disturbance to the concrete surface that may potentially lead to honeycombing. Furthermore, the precise alignment and tight fit of steel formwork play a crucial role in controlling the flow and placement of the concrete. This ensures that all required areas are adequately filled without any gaps or voids, eliminating potential weak points or areas susceptible to honeycombing. In summary, steel formwork offers a dependable and efficient solution for preventing concrete honeycombing by providing a sturdy framework, smooth surfaces, and precise alignment that facilitate the proper filling and curing of the concrete mixture.

- Q: Can steel formwork be used for both simple and complex architectural designs?

- Steel formwork is a versatile option that can be used for both simple and complex architectural designs. It can be shaped and customized to different sizes and shapes, making it suitable for a variety of projects. Its flexibility allows for the creation of intricate and unique forms. In addition, steel formwork offers excellent strength and stability, enabling it to withstand the pressures and forces exerted during the concrete pouring process. This makes it an ideal choice for constructing structures with complex shapes and designs. Moreover, steel formwork is durable and can be reused, making it a cost-effective solution for projects involving both simple and complex architectural designs. Overall, steel formwork is a reliable and efficient option that can be used in a wide range of architectural designs, regardless of their complexity.

- Q: How does steel formwork handle moisture and humidity?

- Steel formwork is highly resistant to moisture and humidity due to its inherent properties and effective protective measures. The steel used in formwork construction is typically treated with anti-corrosion coatings, such as galvanization or epoxy paint, which create a barrier against moisture penetration. These coatings protect the steel from the corrosive effects of water, preventing rust formation and structural degradation. Additionally, steel formwork systems are designed with tight joints and connections to ensure minimal water ingress. This reduces the risk of moisture accumulation within the formwork, which could potentially weaken the structure or affect the quality of the concrete. Furthermore, steel formwork is non-absorbent, meaning it does not absorb water or humidity. This characteristic prevents swelling, warping, or distortion of the formwork due to moisture exposure. It also ensures consistent and accurate dimensions of the formwork, resulting in precise concrete shapes and finishes. In cases where steel formwork is exposed to high levels of moisture or humidity, such as in marine or coastal environments, additional protective measures can be taken. These may include applying specialized coatings or using stainless steel formwork, which offers superior resistance to corrosion and moisture. Overall, steel formwork is well-suited for handling moisture and humidity. Its resistance to corrosion, non-absorbent nature, and ability to maintain structural integrity even in challenging environmental conditions make it a reliable and durable choice for construction projects.

- Q: How does steel formwork affect the overall cost of concrete construction?

- Steel formwork can increase the overall cost of concrete construction due to its higher initial investment compared to other formwork materials. However, it offers several advantages such as durability, reusability, and better quality finishes, which can result in cost savings in the long run by reducing the need for frequent replacements and rework. Additionally, steel formwork allows for faster construction and improved productivity, which can offset the initial cost by reducing labor expenses and project timelines.

- Q: How does steel formwork affect the overall labor requirements of a construction project?

- Steel formwork can significantly reduce the overall labor requirements of a construction project. Its durability and strength allow for faster and more efficient construction processes, reducing the time and effort needed for assembling and disassembling formwork. Additionally, steel formwork is reusable, eliminating the need for repetitive formwork construction and reducing labor costs.

- Q: How does steel formwork accommodate for different concrete pouring heights?

- Steel formwork is a versatile and adjustable system that can easily accommodate different concrete pouring heights. It consists of interlocking steel panels that can be assembled in various configurations, allowing for the creation of customized formwork according to the specific requirements of each construction project. One way steel formwork accommodates for different concrete pouring heights is through the use of adjustable props or supports. These props can be extended or retracted to the desired elevation, providing the necessary support and stability for the formwork. By adjusting the height of the props, the formwork can be easily adapted to accommodate different pouring heights. Additionally, steel formwork often includes adjustable brackets or clamps that can be moved up or down along the vertical bars of the system. These brackets allow for the vertical positioning of the formwork panels, enabling them to be adjusted to the desired height for concrete pouring. Furthermore, steel formwork systems usually have a wide range of panel sizes available, which can be interchanged and combined to achieve the desired height. This flexibility allows for the construction of formwork that perfectly matches the required pouring height, eliminating the need for extensive modifications or customizations. Overall, the adjustable features of steel formwork, such as props, brackets, and interchangeable panels, make it easy to accommodate different concrete pouring heights. This adaptability not only ensures the efficient and precise construction of concrete structures but also saves time and reduces labor costs on construction sites.

- Q: What are the different types of formwork anchors used in steel formwork?

- There are several types of formwork anchors commonly used in steel formwork, including wedge anchors, sleeve anchors, and through-bolt anchors. Wedge anchors are inserted into pre-drilled holes in the steel formwork and are tightened with a wrench to secure the formwork in place. Sleeve anchors are similar to wedge anchors but have a sleeve that expands against the sides of the hole to provide additional stability. Through-bolt anchors consist of a threaded rod that passes through the formwork and is secured with a nut on the opposite side. These anchors offer a strong and reliable connection for steel formwork.

- Q: Can steel formwork be used for precast concrete elements?

- Yes, steel formwork can be used for precast concrete elements. Steel formwork provides durability and strength, making it suitable for manufacturing precast concrete elements. It allows for precise shaping and accurate dimensions, ensuring high-quality and consistent results. Additionally, steel formwork can be easily reused, making it a cost-effective option for precast concrete production.

Send your message to us

Ring-Lock Scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords