Ring-lock scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

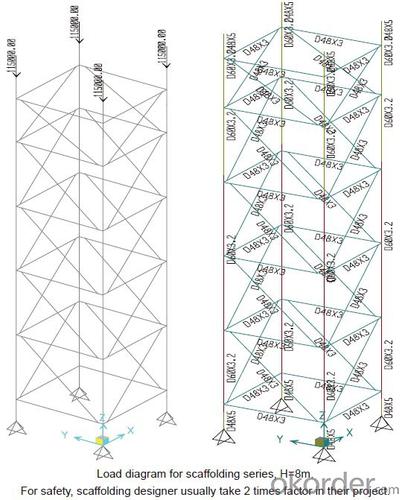

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: How does steel formwork handle concrete shrinkage and expansion?

- Steel formwork offers a versatile and durable option for managing concrete shrinkage and expansion. One of its key advantages lies in its ability to withstand the forces exerted by concrete during these processes. Concrete shrinkage occurs when water evaporates from the mixture, causing the concrete to contract. Steel formwork is well-suited for handling this shrinkage because it provides a rigid structure capable of resisting the inward force exerted by the contracting concrete. The steel panels and beams used in steel formwork are robust and can maintain their shape under pressure, ensuring the formwork remains intact as the concrete shrinks. On the other hand, concrete expansion can occur due to factors like temperature changes or moisture absorption. Steel formwork is designed to accommodate this expansion by incorporating expansion joints. These joints allow the concrete to expand and contract without damaging the formwork. They can be easily adjusted to accommodate the expansion, ensuring the stability and security of the formwork. Apart from its strength and flexibility, steel formwork offers other benefits in managing concrete shrinkage and expansion. It is highly reusable, allowing for dismantling and reassembly in multiple projects. This reduces construction costs and enables easy adjustments in case of changes due to concrete shrinkage or expansion. Moreover, steel formwork provides a smooth and even surface finish to the concrete, minimizing the risk of cracking or unevenness caused by shrinkage. This guarantees a high-quality final concrete structure that meets desired specifications. In conclusion, steel formwork is a reliable and effective solution for managing concrete shrinkage and expansion. Its strength, flexibility, and ability to accommodate these forces make it the preferred choice for construction projects. By utilizing steel formwork, builders can ensure stable, durable concrete structures free from damage caused by shrinkage or expansion.

- Q: What are the different safety training requirements for steel formwork installation?

- The safety training requirements for steel formwork installation may vary depending on the specific regulations and guidelines set by different countries and organizations. However, here are some common safety training requirements that are typically applicable: 1. General Construction Safety Training: All workers involved in steel formwork installation should undergo general construction safety training. This training usually covers topics such as hazard recognition, proper use of personal protective equipment (PPE), fall protection, and proper lifting techniques. 2. Steel Formwork Specific Training: Workers should receive specialized training on the specific techniques and procedures related to steel formwork installation. This training may include topics such as proper assembly and dismantling techniques, securing formwork to prevent collapse, and ensuring stability during concrete pouring. 3. Equipment Training: Workers should be trained on the safe operation of any equipment used during steel formwork installation. This may include training on the safe use of cranes, forklifts, or any other machinery involved in the process. 4. Hazard Communication: Workers should receive training on hazard communication, including understanding safety signs and labels, handling hazardous materials, and knowing how to respond to emergency situations. 5. First Aid and CPR Training: It is important for workers to be trained in first aid and CPR techniques to be prepared for any potential accidents or injuries that may occur during steel formwork installation. 6. Scaffold Safety Training: If scaffolding is used during the installation process, workers should undergo scaffold safety training to ensure they understand how to assemble, use, and dismantle scaffolding safely. 7. Job-Specific Safety Training: Depending on the specific tasks involved in steel formwork installation, workers may need additional job-specific safety training. This could include training on working at heights, working with power tools, or working in confined spaces. It is essential for employers and workers to follow the applicable safety regulations and ensure that all necessary training is provided to create a safe working environment during steel formwork installation.

- Q: Can steel formwork be used in precast concrete applications?

- Yes, steel formwork can be used in precast concrete applications. Steel is a versatile and durable material that can withstand the pressures and forces exerted during the precasting process. It provides excellent support and stability to the concrete during pouring and curing. Steel formwork also allows for precise shaping and detailing of the concrete elements, ensuring accurate dimensions and a high-quality finish. Additionally, steel formwork can be easily assembled and disassembled, making it a suitable choice for repetitive and fast-paced precast production. Overall, steel formwork is widely used in precast concrete applications due to its strength, versatility, and ease of use.

- Q: What are the common safety guidelines when working with steel formwork in confined spaces?

- When working with steel formwork in confined spaces, it is crucial to follow certain safety guidelines to ensure the well-being of the workers involved. Here are some common safety guidelines to consider: 1. Conduct a thorough risk assessment: Before starting any work in a confined space, it is important to assess the potential hazards and risks associated with the task. This assessment should include identifying potential dangers such as inadequate ventilation, limited access, or the presence of hazardous gases. 2. Adequate ventilation: Confined spaces often have limited air circulation, which can lead to a buildup of toxic gases or lack of oxygen. Ensure that the area is properly ventilated before entering and continuously monitor air quality throughout the work. 3. Use appropriate personal protective equipment (PPE): Workers should always wear the necessary PPE, including safety helmets, goggles, gloves, and appropriate respiratory protection. The specific PPE requirements may vary depending on the nature of the confined space and associated hazards. 4. Implement proper lighting: Confined spaces are often poorly lit, making it difficult to see potential hazards and work safely. Adequate lighting should be provided to ensure clear visibility and reduce the risk of accidents. 5. Implement proper entry and exit procedures: Establish clear entry and exit procedures for workers entering and leaving the confined space. This should include proper signage, secure barriers, and a designated person responsible for monitoring and controlling access. 6. Ensure proper communication: Establish a reliable system for communication between workers inside and outside the confined space. This may involve the use of two-way radios, hand signals, or other means of communication to prevent isolation and enable prompt assistance if needed. 7. Regularly inspect equipment and formwork: Prior to starting work, inspect the steel formwork and associated equipment for any damage or defects. Any issues should be promptly addressed to prevent accidents or structural failures. 8. Provide proper training: Workers involved in working with steel formwork in confined spaces should receive appropriate training on safety procedures, hazard recognition, emergency response, and proper use of equipment. Regular training updates should also be conducted to ensure workers remain aware of safety practices. 9. Establish an emergency response plan: Despite taking proper precautions, emergencies can still occur. Establish an emergency response plan that includes procedures for evacuation, rescue, and medical assistance. Ensure that all workers are familiar with the plan and conduct regular drills to practice these procedures. 10. Regularly review and update safety procedures: Safety procedures should be regularly reviewed and updated to incorporate new regulations, industry best practices, or lessons learned from previous incidents. Continuous improvement and monitoring of safety measures are essential to ensure a safe working environment. Remember, working in confined spaces with steel formwork can present significant risks. By following these common safety guidelines and promoting a safety-conscious culture, the risk of accidents and injuries can be minimized, ensuring a safer working environment for all.

- Q: What are the common cost-saving strategies when using steel formwork?

- Some common cost-saving strategies when using steel formwork include reusing the formwork for multiple projects, accurately measuring and cutting the formwork materials to minimize waste, properly maintaining and storing the formwork to prolong its lifespan, and utilizing innovative formwork systems that allow for faster installation and dismantling.

- Q: How does steel formwork affect the overall construction site organization?

- The overall organization of a construction site can be significantly influenced by the use of steel formwork. Firstly, the durability and reusability of steel formwork allow for multiple uses in different projects. This enables better planning and scheduling of construction activities, as the availability of formwork becomes more predictable and reliable. Moreover, the precision and accuracy of steel formwork contribute to higher quality construction. This reduces the need for reworks and delays, as the formwork ensures that concrete is poured accurately and in the right location. As a result, the construction process becomes more efficient, enabling better organization and coordination of various trades and activities on the site. In addition, steel formwork offers design and construction flexibility. It can be easily adjusted and modified to accommodate changes in the project, such as alterations in the shape or size of concrete elements. This adaptability minimizes the need for extra materials and resources, thereby streamlining the organization of the construction site and reducing waste. Furthermore, the strength and stability of steel formwork allow for the construction of taller and larger concrete structures. This can have implications for the overall layout and organization of the site. For instance, it may require additional crane or lifting equipment to handle the heavier and larger formwork components. Therefore, careful planning and coordination are necessary to ensure that the site is properly organized to meet these requirements. To summarize, steel formwork positively impacts the overall organization of a construction site through its durability, precision, flexibility, and strength. These characteristics contribute to better planning, scheduling, and coordination of construction activities, resulting in improved efficiency, quality, and adaptability.

- Q: Can steel formwork be used for both above-ground and underground structures?

- Yes, steel formwork can be used for both above-ground and underground structures. Steel formwork is highly durable and can withstand the pressures and conditions of both environments. It provides excellent strength, stability, and reusability, making it suitable for various construction projects regardless of their location.

- Q: Can steel formwork be used for precast concrete walls?

- Precast concrete walls can indeed utilize steel formwork. Steel formwork is widely employed in the construction industry due to its robustness, longevity, and reusability. It furnishes a stable and sturdy structure for the casting and molding of concrete during the manufacturing process of precast concrete walls. The utilization of steel formwork is appropriate for precast concrete walls because it can endure the pressure exerted by the wet concrete without bending or distorting. It guarantees that the concrete is poured and solidified in the desired shape and dimensions. Additionally, steel formwork can be effortlessly assembled and disassembled, enabling efficient and cost-effective production of precast concrete walls. An added benefit of employing steel formwork for precast concrete walls is its ability to generate smooth finishes. The steel panels or molds can be fashioned to create diverse textures and patterns on the final wall surface. This adaptability allows for increased design options and aesthetic appeal in the end product. Furthermore, steel formwork can be reused numerous times, making it an environmentally friendly and economical choice for precast concrete wall production. The durability of steel ensures that it can withstand the repetitive strains of the manufacturing process without significant deterioration. To summarize, due to its strength, durability, reusability, and capacity to produce smooth finishes, steel formwork is a suitable material for precast concrete walls. It establishes a solid framework for the molding and casting of concrete, permitting efficient and cost-effective production of precast concrete walls.

- Q: How does steel formwork handle different concrete workability levels?

- Steel formwork is a versatile and durable material that can effectively handle different concrete workability levels. Workability refers to the ease with which concrete can be mixed, placed, compacted, and finished. When dealing with concrete of different workability levels, steel formwork offers several advantages. Firstly, its strong and rigid structure can withstand the pressure exerted by concrete during pouring and compaction. This ensures that the formwork remains stable and does not deform or collapse under the weight of the concrete. Additionally, steel formwork provides a smooth and uniform surface for the concrete, regardless of its workability. This is crucial for achieving a high-quality finish and minimizing defects such as honeycombing or uneven surfaces. The smoothness of steel formwork allows for easy and efficient removal, ensuring that the concrete retains its shape and integrity. Moreover, steel formwork can be easily customized and adjusted to accommodate different workability levels. Its modular nature allows for easy assembly and disassembly, making it suitable for various construction projects and concrete types. Steel formwork can be adjusted to accommodate changes in concrete consistency, ensuring that the formwork remains tight and secure. This adaptability is particularly beneficial when working with concrete mixes that have different slump values or consistencies. Another advantage of steel formwork is its reusability. Unlike other types of formwork, such as wooden or plastic formwork, steel formwork can be used multiple times without compromising its structural integrity. This not only reduces construction costs but also allows for efficient handling of concrete with different workability levels. Steel formwork can be easily cleaned, repaired, and reused, making it a cost-effective and sustainable choice for handling various concrete workability levels. In conclusion, steel formwork provides a reliable and adaptable solution for handling different concrete workability levels. Its strength, smoothness, adjustability, and reusability make it an ideal choice for ensuring the stability, quality, and efficiency of concrete construction projects.

- Q: How does steel formwork affect the overall fire resistance of a structure?

- The overall fire resistance of a structure is not directly affected by steel formwork, as its main purpose is temporary support during concrete pouring and construction. The fire resistance of a structure is generally determined by the construction materials, including the type of concrete, insulation, and fireproofing systems. However, steel formwork can indirectly contribute to the fire resistance by ensuring proper placement and compaction of the concrete, which is crucial for achieving the desired fire resistance rating. When mixed and compacted correctly, the strength and durability of the concrete can improve the overall fire resistance of the structure. Moreover, steel formwork can provide a smooth and uniform surface finish, which facilitates the application of fireproofing materials. Fireproofing coatings or sprays are often used to enhance the fire resistance of structural elements like beams and columns. The smooth surface offered by steel formwork helps ensure an even and effective application of these fireproofing materials, thus further improving the fire resistance of the structure. It is important to remember that although steel formwork itself is not fire resistant, it is usually removed once the concrete has cured. The final fire resistance of the structure is determined by the materials used in its permanent construction.

Send your message to us

Ring-lock scaffolding accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords