Ring-Lock Scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

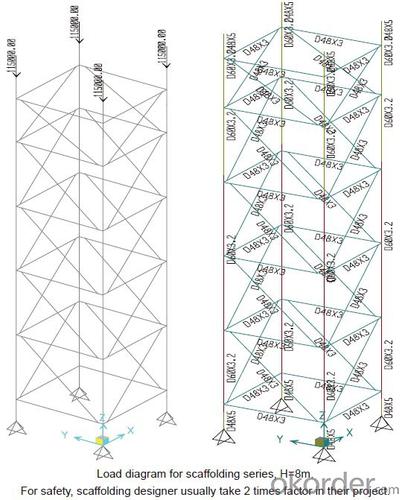

Ring-lock Scaffolding

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: Can steel formwork be used for elevated walkways?

- Steel formwork is indeed suitable for constructing elevated walkways. It is a highly versatile and durable construction material that can be used for various applications, including the construction of elevated walkways. The strength and stability of steel formwork systems make them ideal for supporting the weight and load of a walkway. By using steel formwork for elevated walkways, one can ensure the creation of a safe and robust structure capable of withstanding heavy foot traffic and adverse weather conditions. Moreover, steel formwork allows for flexibility in design, enabling the construction of customized walkways with different shapes and sizes. In conclusion, steel formwork is a reliable choice for constructing elevated walkways due to its strength, durability, and versatility.

- Q: What are the common types of connections used in steel formwork systems?

- Steel formwork systems utilize various types of connections, including wedge connections, pin and wedge connections, bolted connections, clamped connections, and magnetic connections. Wedge connections involve employing a wedge-shaped device to firmly secure the panels together. The wedge is inserted into a slot and tightened, creating a dependable and robust connection. Pin and wedge connections entail using pins and wedges to connect the formwork panels. The pins are inserted through panel holes, and the wedges are then driven into the pins, effectively locking them in position. Bolted connections utilize bolts to connect the formwork panels. Pre-drilled holes are present in the panels, and bolts are inserted through these holes and tightened with nuts. This connection method allows for effortless disassembly and reassembly of the formwork system. Clamped connections employ clamps made of steel to connect the formwork panels. These clamps are tightened using bolts or screws, resulting in a secure and rigid joint between the panels. Magnetic connections rely on magnets to connect the formwork panels. Magnetic strips or plates are embedded in the panels, and when the panels are brought close together, the magnets attract and hold them in place. While this connection method is quick and easy, it may not possess the same strength as other connection methods. Each of these connection types offers distinct advantages and disadvantages. The selection of a connection method depends on various factors, including project requirements, ease of assembly and disassembly, as well as the desired strength and stability of the formwork system.

- Q: What are the different sizes available for steel formwork panels?

- The sizes available for steel formwork panels can vary depending on the manufacturer and project requirements. However, common sizes range from 1.2 meters by 1.8 meters to 2.4 meters by 4.8 meters. These dimensions can be adjusted to accommodate different construction needs and can be found in various thicknesses and configurations.

- Q: Can steel formwork be used in healthcare or medical facility construction projects?

- Yes, steel formwork can be used in healthcare or medical facility construction projects. Steel formwork offers durability, strength, and resistance to wear and tear, making it suitable for projects that require a high level of precision and structural integrity, such as healthcare or medical facilities. Additionally, steel formwork can be easily customized and assembled to meet the specific design requirements of these projects.

- Q: Can steel formwork be used for both simple and complex architectural designs?

- Yes, steel formwork can be used for both simple and complex architectural designs. Steel formwork offers excellent strength and durability, allowing it to handle complex shapes and intricate details with ease. It can be easily assembled and disassembled, making it suitable for various design requirements. Additionally, steel formwork provides a smooth and uniform finish, ensuring high-quality results for both simple and complex architectural designs.

- Q: Is steel formwork more environmentally friendly than other types of formwork?

- There are several reasons why steel formwork is considered to be a more environmentally friendly option than other types of formwork. Firstly, steel is an incredibly durable material that can be reused multiple times, reducing the need for constant production of new formwork materials. This helps to conserve natural resources and minimize waste. Furthermore, steel formwork has a longer lifespan compared to materials like timber or plywood, which often degrade over time and need frequent replacement. This longevity reduces the overall consumption of formwork materials and the associated environmental impact. In addition, steel formwork can be easily recycled at the end of its life, further reducing waste and minimizing the carbon footprint. The recycling process for steel is highly efficient and requires much less energy compared to the production of new steel. This results in significant energy savings and reduced greenhouse gas emissions. Moreover, steel formwork is resistant to moisture and other elements, eliminating the need for chemical treatments to protect it from decay or damage. This reduces the release of harmful substances into the environment, making steel formwork a safer and more sustainable option. However, it is important to consider that the environmental impact of steel formwork can also be influenced by factors such as the manufacturing processes used, transportation distances, and the specific requirements of a project. Therefore, it is crucial to assess the entire life cycle of the formwork and make well-informed decisions based on the specific circumstances to ensure the most environmentally friendly choice.

- Q: Can steel formwork be used in high-rise construction projects?

- Indeed, high-rise construction projects can benefit from the utilization of steel formwork. With its versatility and durability, steel formwork proves to be an excellent choice for constructing concrete structures, especially in the realm of high-rise buildings. This option boasts various advantages, such as its exceptional strength, remarkable dimensional stability, and its ability to endure heavy loads and pressure. Moreover, steel formwork guarantees a smooth finish to the concrete surface and promotes environmental sustainability by allowing for easy reusability. Consequently, this minimizes material wastage and effectively reduces project costs. Furthermore, the adaptability of steel formwork systems enables customization to meet the specific requirements of high-rise construction projects, ultimately ensuring efficient and precise construction processes.

- Q: How does steel formwork differ from other types of formwork?

- There are several ways in which steel formwork differs from other types of formwork. To begin with, steel formwork is renowned for its durability and long lifespan. While wooden or plastic formwork often needs to be replaced frequently due to wear and tear, steel formwork can withstand heavy use and be reused multiple times. As a result, it is a cost-effective option in the long term, as it eliminates the need for constant replacements. Furthermore, steel formwork provides a higher level of precision and accuracy in construction. Its rigid structure ensures that the concrete is poured and cured in the desired shape and dimensions. This is particularly important in projects that require high-quality finishes or intricate architectural designs. Moreover, steel formwork offers excellent structural support. It can endure the pressure exerted by wet concrete without deforming or collapsing, thus ensuring the stability and safety of the construction process. This is especially vital in large-scale projects or situations involving high volumes of concrete. In addition, steel formwork is versatile and easily customizable to meet specific project requirements. It can be swiftly assembled and disassembled, enabling quick and efficient construction processes. Steel formwork can also be adjusted to accommodate various shapes and sizes, making it suitable for a wide range of construction projects. Lastly, steel formwork is highly resistant to weather conditions and environmental factors. Unlike wooden formwork, which may warp or deteriorate when exposed to moisture, steel formwork remains stable and unaffected by changes in temperature or humidity. Consequently, it is suitable for both indoor and outdoor construction projects. In conclusion, steel formwork distinguishes itself from other formwork types due to its durability, precision, structural support, versatility, and resilience to environmental factors. It offers numerous advantages that make it a preferred choice for many construction projects.

- Q: Can steel formwork be used for structures with high thermal insulation requirements?

- Steel formwork is not typically used for structures with high thermal insulation requirements. This is because steel is a good conductor of heat, meaning it allows heat to easily transfer through it. As a result, using steel formwork in structures that require high thermal insulation would lead to significant heat loss, reducing the overall energy efficiency of the building. To achieve high thermal insulation, materials with good thermal resistance such as insulating concrete forms (ICFs), expanded polystyrene (EPS), or other insulated formwork systems are preferred. These materials have low thermal conductivity and provide a barrier against heat transfer. By using such materials, structures can meet the high thermal insulation requirements and improve energy efficiency. However, it is worth mentioning that steel formwork can still be used in combination with insulation materials to provide structural support and form the shape of the structure. In this case, additional insulation measures, such as applying insulation layers or using insulation inserts, would be necessary to enhance the thermal performance of the structure. Overall, while steel formwork can be suitable for many construction projects, it is not the ideal choice for structures with high thermal insulation requirements.

- Q: What are the different types of steel formwork joint solutions?

- There are several types of steel formwork joint solutions used in construction projects. These joint solutions are designed to provide stability, strength, and flexibility to the formwork system. Some of the commonly used types of steel formwork joint solutions include: 1. Butt Joint: This is a simple and commonly used joint where two steel formwork panels are joined together by aligning the edges and securing them with bolts or clamps. Butt joints are easy to assemble and disassemble, making them suitable for various construction applications. 2. Corner Joint: As the name suggests, corner joints are used when two steel formwork panels meet at a corner. These joints are typically formed by overlapping the panels and securing them with bolts or clamps. Corner joints provide stability and reinforcement to the formwork system, particularly in areas where walls or columns are being constructed. 3. T-Joint: T-joints are used when three steel formwork panels meet at one point. This joint solution is formed by overlapping the panels and securing them with bolts or clamps. T-joints are commonly used in construction projects where complex shapes or structures are being built. 4. L-Joint: L-joints are similar to T-joints but involve only two steel formwork panels meeting at right angles. These joints are formed by overlapping the panels and securing them with bolts or clamps. L-joints are used to create corners in formwork systems, such as when constructing columns or beams. 5. Hinged Joint: Hinged joints are used when there is a need for flexibility in the formwork system. These joints allow the formwork panels to pivot or rotate, accommodating changes in shape or position. Hinged joints are commonly used in curved or irregular structures where rigid joints may not be suitable. 6. Adjustable Joint: Adjustable joints are used when there is a requirement for height or width adjustment in the formwork system. These joints allow for easy modification of the formwork dimensions to accommodate changes in design or construction requirements. Adjustable joints are particularly useful in projects that involve varying dimensions or levels. It is important to select the appropriate steel formwork joint solution based on the specific construction requirements and structural design. Proper installation and reinforcement of these joints ensure the stability and integrity of the formwork system, which is crucial for the successful execution of the construction project.

Send your message to us

Ring-Lock Scaffolding Accessories for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords