Ring-lock Scaffolding Accessories for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ring-lock Scaffolding

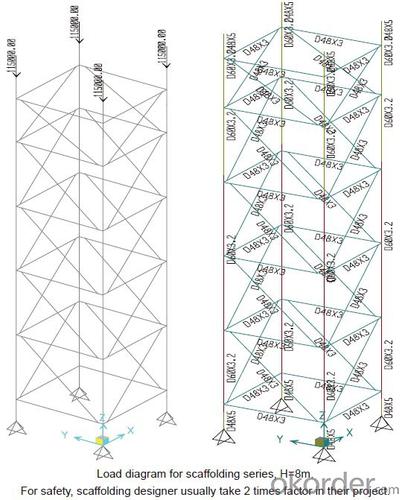

A support system for construction, ownsadvantages of both cup-lock scaffolding andshoring tower.

It is in the development direction of new typescaffolding.

It is widely used in buildings, bridges, tunnels etc..

Characteristics:

◆ Easy to storage and transportation

◆ High degree of standardization

◆ Easy and quick erection

◆ Excellent stability and bearing capacity

- Q: What are the different locking mechanisms used in steel formwork?

- To ensure stability and integrity in concrete construction projects, various locking mechanisms are employed in steel formwork. These mechanisms are designed to securely fasten the formwork panels together, preventing any shifting or movement that could compromise the accuracy and quality of the final concrete structure. One widely used locking mechanism is the wedge clamp system. This system utilizes steel wedges, which are inserted between the formwork panels and tightened with a hammer or mallet. The wedges establish a robust connection between the panels, firmly anchoring them in place. Another popular locking mechanism is the pin and wedge system. This system involves the insertion of steel pins through holes in the formwork panels. Subsequently, steel wedges are driven into these holes, securing the pins firmly. This creates a stable and secure connection between the panels. Some steel formwork systems also employ a hook and loop mechanism. This entails the attachment of metal hooks to one panel and metal loops to the neighboring panel. The hooks and loops interlock, providing a strong connection between the panels. This mechanism is often favored for its convenience and efficiency, making it a popular choice for specific construction projects. Moreover, certain steel formwork systems combine different locking mechanisms. For instance, a system may incorporate both wedge clamps and pin and wedge systems to enhance stability and strength. Ultimately, the various locking mechanisms employed in steel formwork serve the purpose of ensuring the secure connection of formwork panels throughout the concrete pouring process. Each mechanism offers its own advantages and may be more suitable for specific project requirements.

- Q: What are the different types of ties used in steel formwork construction?

- There are several types of ties commonly used in steel formwork construction. These ties serve the purpose of holding the formwork panels together and ensuring the stability and integrity of the structure. Some of the different types of ties used in steel formwork construction include: 1. Snap ties: These are the most commonly used ties in steel formwork construction. They consist of two parts - a metal rod and a flat plate. The rod is inserted through holes in the formwork panels, and the plate is then attached to hold the panels together. Snap ties are quick and easy to install and can be easily removed after the concrete has cured. 2. Tie rods: These are long steel rods that are threaded on both ends. They are used to hold the formwork panels together by passing them through holes in the panels and securing them with nuts and washers. Tie rods provide strong and stable connections between the panels and can withstand high pressure and loads. 3. She-bolts: These are similar to tie rods but have a fixed female thread at one end. She-bolts are used in combination with wing nuts and washers to hold the formwork panels together. They are particularly useful in applications where the tie rods need to be quickly and easily removed. 4. Flat ties: These are steel wires or bars that are flat in shape. They are inserted through holes in the formwork panels and secured with cones or washers. Flat ties provide a secure connection between the panels and are commonly used in large-scale construction projects. 5. Coil ties: These are flexible steel wires that are coiled at one end and have a threaded end at the other. Coil ties are inserted through holes in the formwork panels and secured with cones or washers. They are particularly useful in curved or irregular-shaped structures. 6. Combination ties: These ties combine the features of snap ties and tie rods. They consist of a metal rod with a flat plate at one end and a threaded end at the other. Combination ties are versatile and can be used in various formwork applications. It is important to choose the appropriate type of tie based on the specific requirements of the steel formwork construction project. The choice of tie will depend on factors such as the size and shape of the structure, the load-bearing capacity needed, and the ease of installation and removal.

- Q: Can steel formwork be used for elevated concrete slabs?

- Yes, steel formwork can be used for elevated concrete slabs. Steel formwork is known for its strength and durability, making it suitable for supporting the weight and pressure of concrete during construction. It provides a stable and rigid framework for pouring and shaping concrete, ensuring the formation of high-quality elevated slabs.

- Q: How does steel formwork affect the overall construction site safety?

- Steel formwork can significantly enhance overall construction site safety. Its strength and durability ensure stability and structural integrity during concrete pouring and curing processes. The use of steel formwork reduces the risk of formwork collapse or failure, which can cause serious accidents and injuries. Additionally, steel formwork's fire-resistant properties provide an added layer of safety, minimizing the potential for fire-related incidents. Overall, steel formwork promotes a safer construction site by reducing potential hazards and enhancing the structural stability of the project.

- Q: Are there any limitations to the size of concrete pours with steel formwork?

- Steel formwork poses limitations for large concrete pours due to various factors. Firstly, the weight and size of the steel formwork itself can be challenging. Maneuvering heavy and large steel formwork can prove difficult, particularly for sizable pours. Moreover, additional supports and bracing are necessary for larger pours. To prevent bending or collapsing under the concrete's weight, steel formwork often requires reinforcement and bracing. This increases the installation's complexity and cost. Additionally, the size and weight of the concrete become limiting factors. Curing large concrete pours generates substantial heat, potentially causing thermal cracking and durability issues. Steel formwork may not endure the intense temperatures and pressures produced by substantial volumes of concrete, leading to deformation or failure. Furthermore, the logistics and transportation of large concrete pours present challenges. Limited availability of concrete trucks and pumps capable of transporting significant volumes can result in delays and escalated expenses. In summary, steel formwork is suitable for diverse concrete pours, but its usage for larger and complex projects necessitates careful evaluation. Assessing project-specific requirements and constraints is crucial to determine the feasibility and appropriateness of employing steel formwork for sizable concrete pours.

- Q: What are the considerations when designing steel formwork for architectural features?

- Several important considerations need to be taken into account when designing steel formwork for architectural features. These considerations encompass: 1. Structural integrity: To withstand construction loads and pressures, the formwork must be designed accordingly. This includes considering the weight of the concrete and any additional forces like wind or seismic activity. 2. Dimensional accuracy: Architectural features often demand precise dimensions and shapes. Hence, the steel formwork must be designed to meet these requirements. Adjustable components or additional supports may be utilized to maintain the desired shape. 3. Aesthetic appeal: Architectural features aim to be visually appealing. Therefore, the formwork should be designed in a way that allows for the desired aesthetic to be achieved. This may involve using special finishes or textures on the formwork surface, or incorporating decorative elements into the design. 4. Ease of assembly and disassembly: The design of steel formwork should prioritize easy assembly and disassembly. This promotes efficient construction processes and reduces the time and effort required for installation and removal. 5. Reusability: It may be desirable to reuse the steel formwork for multiple projects. With this in mind, the formwork should be designed to minimize waste and reduce costs in the long term. This may involve using durable materials and incorporating features that allow for easy disassembly and reassembly. 6. Safety: Safety is of utmost importance in construction projects. Therefore, the formwork needs to be designed with worker safety in mind. This may involve incorporating safety features such as handrails, non-slip surfaces, or fall protection systems. In conclusion, designing steel formwork for architectural features necessitates careful consideration of structural integrity, dimensional accuracy, aesthetic appeal, ease of assembly, reusability, and safety. By addressing these considerations, a well-designed steel formwork system can facilitate the construction of visually appealing and structurally sound architectural features.

- Q: What are the considerations when designing steel formwork for foundations?

- When designing steel formwork for foundations, there are several important considerations that need to be taken into account. Firstly, the load-bearing capacity of the formwork needs to be carefully calculated and designed to ensure it can support the weight of the concrete being poured. The formwork must be able to withstand the pressure and weight of the liquid concrete without deforming or collapsing. The strength and thickness of the steel used for the formwork will play a crucial role in determining its load-bearing capacity. Another consideration is the shape and size of the foundation. The formwork needs to be designed to accurately replicate the desired shape and dimensions of the foundation. This requires careful planning and measurement to ensure the formwork is properly aligned and positioned before pouring the concrete. Any inaccuracies in the formwork can result in a foundation that is not level or properly aligned, which can compromise the structural integrity of the entire building. Furthermore, the formwork needs to be designed with the ease of installation and removal in mind. Steel formwork systems that are modular or adjustable can greatly improve the efficiency of the construction process. This allows for easy assembly and disassembly of the formwork, reducing labor and time requirements. Additionally, provisions should be made for easy access to the foundation for any necessary inspections or repairs during and after construction. Lastly, the durability and longevity of the steel formwork should be considered. Steel is known for its strength and durability, but precautions should still be taken to protect the formwork from environmental factors such as corrosion. Applying protective coatings or using galvanized steel can help prevent rust and extend the lifespan of the formwork. In summary, when designing steel formwork for foundations, considerations such as load-bearing capacity, accuracy of shape and size, ease of installation and removal, and durability are vital to ensure a successful and structurally sound foundation.

- Q: Can steel formwork be used for precast concrete facades?

- Indeed, precast concrete facades can utilize steel formwork. The utilization of steel formwork entails the establishment of a robust and long-lasting framework for the pouring and molding of the precast concrete panels that constitute the facade. This method presents numerous advantages, encompassing remarkable strength, stability, and the capacity to fashion intricate designs and intricate elements. Moreover, steel formwork possesses the added benefits of effortless removal and reusability, rendering it an economically viable solution for the production of precast concrete facades. Nevertheless, it is imperative to ensure that the steel formwork is meticulously designed and fabricated to satisfy the distinct requirements of the project and the aesthetic preferences associated with the facade.

- Q: How does steel formwork handle concrete pouring in cold weather?

- Steel formwork is a popular choice for concrete pouring in cold weather due to its excellent stability and durability. Cold weather conditions can pose challenges during concrete pouring, such as the risk of freezing, slower curing, and reduced strength development. However, steel formwork effectively handles these issues and ensures a successful concrete pour. Firstly, steel formwork provides a strong and rigid structure that can withstand the external pressure exerted by the concrete. This stability prevents any deformation or collapse of the formwork, which is crucial for ensuring the integrity of the concrete structure. Secondly, steel formwork acts as a thermal barrier, protecting the concrete from the cold temperatures. The steel material has lower thermal conductivity compared to other formwork materials like wood or plywood. As a result, it helps to retain the heat generated during the hydration process of concrete, allowing it to cure properly even in cold weather. Additionally, steel formwork can be easily insulated to further enhance its ability to handle concrete pouring in cold weather. Insulation materials like foam panels or blankets can be attached to the steel formwork, providing an additional layer of protection against the cold temperatures. This insulation helps to maintain the required temperature for proper concrete curing, preventing any potential freezing or delays in the setting process. Lastly, steel formwork enables efficient heating methods to be implemented during concrete pouring in cold weather. Electrical heating systems or radiant heaters can be used to warm the steel formwork, maintaining the desired temperature for the concrete. This ensures that the concrete cures at the appropriate rate, leading to adequate strength development and minimizing any negative effects of the cold weather. In conclusion, steel formwork is well-suited to handle concrete pouring in cold weather conditions. Its stability, thermal properties, and insulation capabilities make it a reliable choice for maintaining the required temperature and ensuring successful concrete curing in colder temperatures.

- Q: Can steel formwork be used for complex geometric designs?

- Yes, steel formwork can be used for complex geometric designs. Its strength and durability allow for intricate shapes and patterns to be created, providing flexibility in design and construction.

Send your message to us

Ring-lock Scaffolding Accessories for Formwork and Scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords