Reinforced Steel Bar Hrb400B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforced Steel Bar Hrb400B

Description of Reinforced Steel Bar Hrb400B

1, Diameter: 5.5mm-10mm Reinforced Steel Bar Hrb400B

10m- 40mm Reinforced Steel Bar Hrb400B

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Reinforced Steel Bar Hrb400B

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

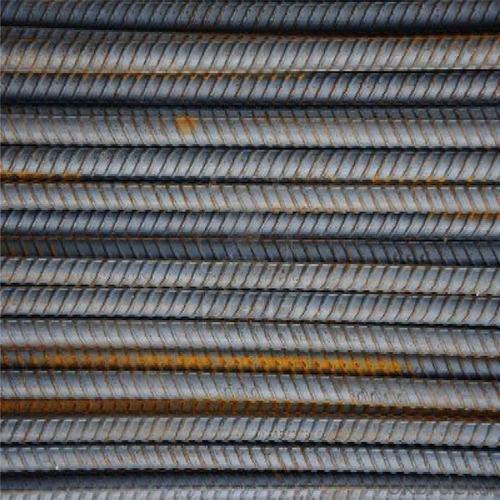

Products Show of Reinforced Steel Bar Hrb400B

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the benefits of using special steel in the energy sector?

- There are several benefits of using special steel in the energy sector. Firstly, special steel offers exceptional strength and durability, making it an ideal material for constructing various energy infrastructure components such as pipelines, pressure vessels, and turbines. Its high tensile strength and resistance to corrosion ensure that these structures can withstand the harsh conditions and pressures encountered in the energy sector, reducing the risk of failures and increasing their lifespan. Secondly, special steel exhibits excellent heat resistance properties, which is crucial in the energy sector where high temperatures are generated. This makes it suitable for applications such as power generation, where it can be used in the construction of boilers, heat exchangers, and nuclear reactors. The ability of special steel to withstand extreme heat without deforming or losing its mechanical properties is vital for ensuring the safe and efficient operation of energy facilities. Moreover, special steel offers superior weldability and formability, allowing for easier fabrication and assembly of complex energy infrastructure components. This makes it easier and more cost-effective to manufacture and install equipment in the energy sector, reducing both production costs and construction time. Another advantage of using special steel in the energy sector is its resistance to fatigue and cracking. Energy infrastructure components are subjected to cyclic loading and stress, which can lead to fatigue failure over time. Special steel's ability to resist fatigue and crack propagation ensures the long-term reliability and safety of energy infrastructure. Furthermore, special steel offers excellent magnetic properties, making it suitable for use in power transmission and electrical equipment. Its magnetic permeability and low electrical resistance allow for efficient transmission and distribution of electricity, reducing energy losses and improving overall system performance. Overall, the benefits of using special steel in the energy sector include enhanced strength, durability, heat resistance, weldability, and fatigue resistance. These properties contribute to the reliability, safety, and efficiency of energy infrastructure, making special steel an invaluable material for the energy sector.

- Q: What are the different machining methods for special steel?

- There are several machining methods for special steel, including turning, milling, drilling, grinding, and EDM (Electrical Discharge Machining). Each method has its own advantages and is selected based on factors such as the complexity of the part, required precision, surface finish, and material hardness.

- Q: What are the properties of case-hardening steel?

- Case-hardening steel typically has a low carbon content, making it relatively soft and ductile. However, when subjected to a specialized heat treatment process, such as carburizing or nitriding, the surface of the steel becomes hardened while the core remains relatively tough. This allows case-hardening steel to possess excellent wear resistance and high surface hardness, making it ideal for applications that require both strength and durability, such as gears, shafts, and other mechanical components.

- Q: How does special steel contribute to the automotive racing aftermarket industry?

- Special steel plays a crucial role in the automotive racing aftermarket industry by providing the necessary strength, durability, and performance required for high-performance racing vehicles. In this industry, where speed, precision, and safety are paramount, special steel offers unique properties that enable engineers and manufacturers to push the limits of performance. One key way that special steel contributes to the automotive racing aftermarket industry is through its ability to withstand extreme conditions. Racing vehicles are subjected to intense heat, pressure, and vibrations during high-speed races, which can put immense stress on various components. Special steel, with its exceptional heat resistance and high tensile strength, ensures that critical parts like engine components, transmission gears, and suspension systems can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel is known for its lightweight properties, making it an ideal material for racing vehicle components. Weight reduction is a crucial aspect of racing as it directly impacts acceleration, handling, and overall performance. By using special steel, manufacturers can create lighter yet stronger components, allowing racing teams to achieve higher speeds, better maneuverability, and improved fuel efficiency. Special steel also contributes to the automotive racing aftermarket industry by offering excellent machinability and weldability. This allows for precise customization and modification of components, catering to the specific needs and preferences of racing teams. Whether it is creating custom engine blocks, exhaust systems, or chassis reinforcements, special steel provides the flexibility required to optimize performance and gain a competitive edge. Moreover, the use of special steel in the automotive racing aftermarket industry promotes innovation and technological advancements. Steel manufacturers continually develop new alloys and compositions that enhance the performance capabilities of racing vehicles. These advancements can include improved corrosion resistance, better fatigue strength, and enhanced material properties, all of which contribute to the overall performance and longevity of racing vehicle components. In summary, special steel is a vital contributor to the automotive racing aftermarket industry. Its unique combination of strength, durability, lightweight properties, and machinability enables racing teams to design and manufacture high-performance vehicles that can withstand extreme conditions. By leveraging the advantages of special steel, the industry can continue to push the boundaries of automotive racing, delivering faster, safer, and more efficient racing machines.

- Q: How does special steel contribute to the manufacturing of fasteners?

- Special steel is an essential material in the manufacturing of fasteners due to its unique properties and characteristics. Firstly, special steel offers high strength and durability, making it ideal for the production of fasteners that are required to withstand heavy loads and high levels of stress. This ensures that the fasteners can securely hold components together without breaking or becoming loose over time. Additionally, special steel is known for its excellent corrosion resistance. Fasteners are often exposed to various environmental conditions, including moisture, chemicals, and extreme temperatures. The corrosion resistance of special steel helps to prevent rust and deterioration, ensuring the longevity and reliability of the fasteners. Furthermore, special steel can be easily formed, machined, and heat-treated, allowing for the production of fasteners with precise dimensions and customized designs. This versatility in manufacturing processes enables the creation of fasteners that can meet specific application requirements, such as different thread types, sizes, and head styles. Moreover, special steel offers excellent wear resistance and hardness, which is crucial for fasteners that are subjected to repetitive motions or constant friction. The hardness of special steel helps the fasteners maintain their shape and integrity, reducing the risk of deformation or failure during operation. Overall, special steel plays a vital role in the manufacturing of fasteners by offering high strength, corrosion resistance, versatility in manufacturing processes, and excellent wear resistance. These properties ensure that fasteners are reliable, long-lasting, and capable of withstanding the demands of various industries, including automotive, aerospace, construction, and machinery.

- Q: What are the advantages of using special steel in construction?

- There are several advantages of using special steel in construction. Firstly, special steel offers superior strength and durability, making it ideal for high-rise buildings and structures that require enhanced structural integrity. Additionally, special steel has excellent corrosion resistance properties, which significantly increases the lifespan of a structure, especially in harsh environments. Furthermore, special steel can be customized and fabricated into various shapes, allowing for flexible and innovative architectural designs. Lastly, special steel is a sustainable and eco-friendly material, as it is recyclable and reduces the need for new resources, thereby contributing to a more sustainable construction industry.

- Q: What are the different non-destructive testing methods used for special steel?

- Some of the common non-destructive testing methods used for special steel include ultrasonic testing, magnetic particle testing, liquid penetrant testing, radiographic testing, and eddy current testing. These methods allow for the detection of internal and surface defects in the steel without causing any damage or alteration to the material.

- Q: What are the common challenges in heat treatment of special steel?

- The heat treatment of special steel presents several common challenges that need to be carefully addressed in order to achieve desired material properties. One of the key challenges is the need for precise temperature control during the heating and cooling processes. Special steels often have specific heat treatment temperature ranges that need to be strictly followed to achieve the desired microstructure and mechanical properties. Failure to maintain precise temperature control can result in inadequate or inconsistent heat treatment, leading to suboptimal material performance. Another challenge is the potential for distortion or warping of the steel components during the heat treatment process. Special steels often have complex shapes or intricate designs, making them more susceptible to distortion when exposed to high temperatures. This distortion can negatively impact the dimensional accuracy and overall quality of the final product. Hence, careful consideration must be given to the selection of appropriate heating and cooling methods, as well as the use of fixtures or jigs to minimize distortion. Furthermore, special steels may contain alloying elements that can have a significant influence on the heat treatment process. Alloying elements such as chromium, molybdenum, or vanadium can alter the hardenability, tempering response, or transformation behavior of the steel. These elements may introduce additional challenges when determining the optimal heat treatment parameters, as their presence can necessitate adjustments to the heating and cooling rates, soak times, or quenching media. Lastly, achieving uniformity in heat treatment across a batch of special steel components can be a challenge. Variations in size, shape, or composition within a batch can lead to inconsistent heat treatment results. Controlling the heating and cooling rates, ensuring proper circulation of the heat treatment media, and implementing effective process monitoring techniques are essential for achieving consistent and uniform material properties. In conclusion, the common challenges in heat treatment of special steel include precise temperature control, distortion/warping, the influence of alloying elements, and achieving uniformity across a batch. Addressing these challenges requires a thorough understanding of the steel's composition, careful process planning, and the use of appropriate process controls and monitoring techniques.

- Q: Can special steel be used in the production of consumer goods?

- Yes, special steel can be used in the production of consumer goods. Special steel offers enhanced properties such as high strength, durability, corrosion resistance, and heat resistance, making it suitable for various consumer goods applications. It can be utilized in the manufacturing of kitchen utensils, cutlery, appliances, automotive parts, tools, and more, ensuring improved performance and longevity of these products.

- Q: How does the cost of special steel compare to regular steel?

- The cost of special steel is generally higher compared to regular steel. Special steel is specifically designed and produced to possess exceptional properties and characteristics that regular steel does not have. It undergoes additional processes such as alloying, heat treatment, or specialized manufacturing techniques to enhance its strength, durability, corrosion resistance, and other desirable attributes. These added steps in production increase the overall cost of special steel. On the other hand, regular steel is more readily available and is produced on a larger scale. It is often used for general purposes and applications where high-performance qualities are not required. Regular steel is relatively cheaper due to its lower production costs and wider availability in the market. However, it is important to note that the cost comparison between special steel and regular steel can vary depending on various factors such as the specific type of steel, the quantity being purchased, market conditions, and any additional customization required. Therefore, it is advisable to consult with steel suppliers or specialists to get accurate pricing information based on specific requirements.

Send your message to us

Reinforced Steel Bar Hrb400B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 160 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords