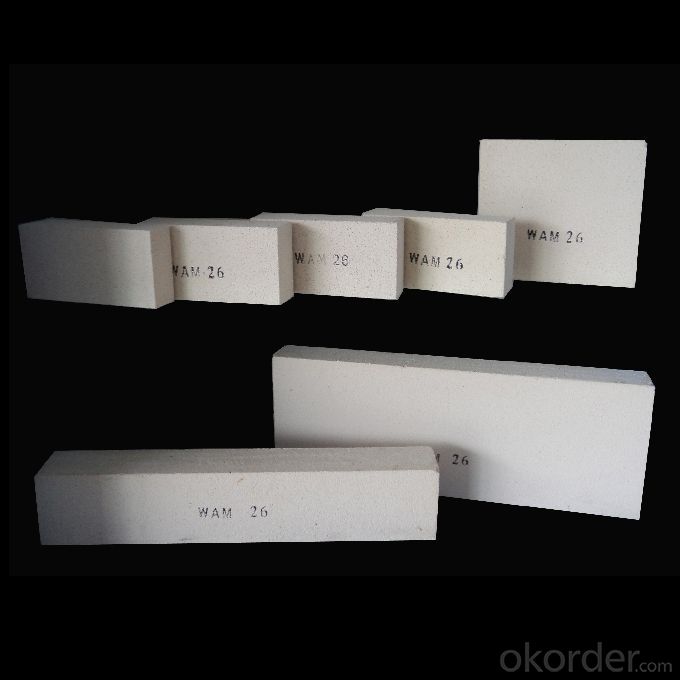

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in the construction of pizza ovens?

- Indeed, it is possible to utilize insulating fire bricks during the construction of pizza ovens. With their ability to endure extreme temperatures and offer exceptional insulation, these bricks become an excellent choice for pizza ovens. They aid in the efficient preservation of heat, thus leading to a more uniform and steady cooking temperature. Additionally, due to their low thermal conductivity, insulating fire bricks effectively prevent heat dissipation, ensuring that the pizza oven remains hot for extended durations, thereby enhancing energy efficiency. All in all, incorporating insulating fire bricks into the pizza oven construction process can result in enhanced heat retention, improved cooking performance, and a more energy-efficient operation.

- Q: What are the different types of insulating fire bricks available in the market?

- There are several different types of insulating fire bricks available in the market. Some of the most common types include: 1. Lightweight Fire Bricks: These bricks are made from lightweight and porous materials, such as expanded clay, vermiculite, or perlite. They offer excellent insulation properties and are commonly used in applications where weight is a concern, such as for lining the walls of kilns or furnaces. 2. Ceramic Fiber Bricks: These bricks are made from ceramic fibers that are compressed and formed into bricks. They have high insulating properties, low thermal conductivity, and can withstand high temperatures. Ceramic fiber bricks are often used in applications that require high-temperature insulation, such as in the construction of industrial furnaces or ovens. 3. Calcium Silicate Bricks: These bricks are made from a combination of lime, silica, and reinforcing fibers. They have good thermal insulation properties and are resistant to thermal shock. Calcium silicate bricks are commonly used in applications where high-temperature insulation is required, such as in the construction of boilers or incinerators. 4. Magnesia Bricks: These bricks are made from magnesium oxide, which is a highly refractory material. They have excellent thermal insulation properties and can withstand extremely high temperatures. Magnesia bricks are often used in applications that require insulation in high-temperature environments, such as in the lining of steel-making furnaces or glass melting tanks. 5. Vermiculite Bricks: These bricks are made from expanded vermiculite, which is a naturally occurring mineral. They have good insulation properties, low thermal conductivity, and are resistant to high temperatures. Vermiculite bricks are commonly used in applications that require lightweight insulation, such as in the construction of chimneys or fireplace surrounds. Overall, the choice of insulating fire bricks depends on the specific requirements of the application, such as the desired level of insulation, temperature resistance, and weight considerations.

- Q: Are insulating fire bricks resistant to chemical attack?

- Insulating fire bricks are generally known for their resistance to chemical attack. These bricks consist of high-purity refractory materials, such as alumina or silica, which possess excellent chemical stability. Their design allows them to endure high temperatures, making them highly resistant to the corrosive effects of chemicals. However, it's worth noting that the extent of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical used. In some instances, certain aggressive chemicals may still cause gradual degradation or erosion. Hence, it is always advisable to consult the manufacturer or supplier for precise information regarding the chemical resistance of insulating fire bricks, considering their intended application.

- Q: Are insulating fire bricks resistant to cracking under pressure?

- Yes, insulating fire bricks are resistant to cracking under pressure. These bricks are specifically designed to withstand high temperatures and mechanical stress. They are made from lightweight materials with low thermal conductivity, such as ceramic fiber or lightweight aggregates, which allow them to retain their structural integrity even when subjected to pressure or thermal expansion. Additionally, insulating fire bricks often have a high percentage of alumina content, which enhances their strength and resistance to cracking. These properties make them an ideal choice for applications that require insulation and structural stability, such as furnaces, kilns, and high-temperature industrial processes. However, it is important to note that excessive pressure or sudden temperature changes can still cause damage to insulating fire bricks, so proper installation and maintenance guidelines should be followed to ensure their longevity and performance.

- Q: Can insulating fire bricks be used in the construction of glassware molds?

- Insulating fire bricks are indeed applicable for the construction of glassware molds due to their exceptional insulation properties. These bricks, crafted from lightweight materials, possess excellent insulation capabilities, rendering them suitable for deployment in high-temperature scenarios like glassware molds. They can withstand the extreme heat generated during the glass molding process and contribute to maintaining a steady temperature within the mold. Moreover, these bricks exhibit low thermal conductivity, which prevents excessive heat dissipation and ensures efficient energy utilization. All in all, by incorporating insulating fire bricks into the construction of glassware molds, one can achieve superior heat retention, enhanced thermal efficiency, and improved mold stability, ultimately leading to the production of higher quality glass products.

- Q: Are insulating fire bricks resistant to alkali-silica reaction?

- IFBs do not possess inherent resistance against alkali-silica reaction (ASR), which is a chemical reaction occurring between the alkalis from cement and reactive forms of silica found in aggregates. This reaction can result in the formation of a gel that expands and causes cracks in concrete structures. Although IFBs are typically constructed from refractory materials engineered to withstand high temperatures and thermal shock, they lack specific properties to combat ASR. The refractory material's composition and characteristics determine its resistance to ASR when used in IFBs. Should the refractory material utilized in an IFB contain reactive forms of silica like quartz or cristobalite, and there is exposure to alkalis, the possibility of ASR occurring exists. However, if the refractory material has a low content of reactive silica or contains additives that can mitigate ASR, the risk of ASR can be minimized. It is essential to recognize that the primary function of IFBs is to provide insulation in high-temperature applications, such as kilns, furnaces, and fireplaces. If ASR resistance is a crucial requirement for a specific application, it is advisable to consult the manufacturer or a materials engineer to determine the suitability of the IFB for that particular scenario.

- Q: Can insulating fire bricks be used in chemical processing plants?

- Indeed, chemical processing plants can utilize insulating fire bricks. These bricks are specifically engineered to endure elevated temperatures and offer exceptional thermal insulation. Consequently, they are suitable for a wide range of industrial applications, including chemical processing plants. They can be employed to line furnaces, kilns, reactors, and other apparatuses where high temperatures are involved. The exceptional thermal insulation properties of insulating fire bricks aid in reducing heat loss, enhancing energy efficiency, and maintaining a steady temperature within the processing equipment. Furthermore, these bricks exhibit resistance to chemical corrosion and can withstand the rigorous conditions typically encountered in chemical processing plants. Ultimately, insulating fire bricks serve as a dependable and efficient choice for insulating and safeguarding equipment in chemical processing plants.

- Q: Are insulating fire bricks suitable for use in kilns and furnaces?

- Yes, insulating fire bricks are suitable for use in kilns and furnaces. They are designed to have excellent insulation properties, which helps to reduce heat loss and improve energy efficiency in these high-temperature environments. Additionally, insulating fire bricks can withstand the extreme temperatures found in kilns and furnaces without cracking or breaking, making them a reliable and durable choice.

- Q: Can insulating fire bricks be used in the construction of thermal insulation walls?

- Yes, insulating fire bricks can be used in the construction of thermal insulation walls. Insulating fire bricks are specially designed bricks that have a low thermal conductivity, which means they are excellent at preventing the transfer of heat. This makes them ideal for use in thermal insulation applications. When constructing thermal insulation walls, insulating fire bricks can be used as the primary material or in conjunction with other insulation materials such as foam boards or mineral wool. These bricks are typically lightweight, which makes them easier to handle and install. They also have high temperature resistance, allowing them to withstand the heat generated by fireplaces, ovens, or other heat-producing appliances. Insulating fire bricks offer several benefits for thermal insulation walls. They help to minimize heat loss or gain, thereby improving energy efficiency in buildings. They also help to reduce noise transmission, making them suitable for soundproofing applications. It is important to note that insulating fire bricks may not be suitable for all types of walls or building structures. Factors such as building codes, environmental conditions, and specific requirements of the project should be considered when determining if insulating fire bricks are the appropriate choice for thermal insulation walls. Consulting with a professional architect or engineer is recommended to ensure the best insulation solution for a specific construction project.

- Q: Are insulating fire bricks suitable for use in thermal power plants?

- Yes, insulating fire bricks are suitable for use in thermal power plants. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and prevent heat loss. In thermal power plants, where high temperatures are generated, insulating fire bricks can be used as linings for furnaces, boilers, and other equipment to provide thermal insulation and increase energy efficiency. Additionally, these bricks are resistant to high temperatures and can withstand thermal shocks, making them ideal for use in environments with extreme heat. By using insulating fire bricks in thermal power plants, operators can reduce heat loss, increase the overall efficiency of the plant, and improve the durability and lifespan of the equipment.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick GJM28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords