Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

light insulation brick

1. refractories

2. silica insulation brick

3. light insulation brick

4. glass furnace

Refractory mullite insulating refractory brick JM 23

Okorder series heat insulation brick

Okorder series thermal insulation brick is an effective, energy saving, low carbon, environmental protection advanced, according to the ASTM standard manufacturing products. Okorder series products are best Li Ning and insulation in all types of industrial furnaces in the metallurgical field, aluminum, petrochemical, electric power and glass ceramic materials. They can be used as part of the working layer of thermal insulation or non - melting. Products have been widely used in the following furnace, achieved satisfactory results.

Application of heat preservation brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen production furnace, primary reformer, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc..

Advantages of heat insulation brick

Low thermal conductivity: more porosity will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage to absorb more heat, energy-saving effect is obvious.

Gao Chundu: iron, alkali metal impurity content is low.

The precise size: Brick size processing precision, special shape cutting and grinding, accelerate the brickwork.

Insulating brick picture

Common problem solutions

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality certificate of the raw material is required, each batch of the products are to be tested in the use of the forward line. In the production process, the quality control by the workers, and then each piece of classification, and through the quality supervision and inspection.

3. Can you give me a brief introduction to the application of your product?

My company is mainly engaged in refractories in the steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. What information do you need if I need you?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product application, etc..

If you have any questions, please contact us.

Product Description

Light insulation brick

Description

The insulating firebricks are made from high purify raw materials and follows the ASTM C155 classification. These IFB’s contain a carefully graded organic filler which is burned out during firing to give a uniform controlled pore structure and after are machined to precise tolerances on all surfaces.

Features

- Use limit up to 1760°C

- Excellent strength and thermal stability

- Low thermal conductivity

- Low Heat Storage

- High Purity

- Very big range of available sizes and formats

- Very accurate dimensions

Applications

Recommended as hot face and backup insulation in all industries and applications.

Special Shapes

In addition to the standard brick sizes, our bricks are available in pre-machined special shapes as well as Suspended Roof Blocks!

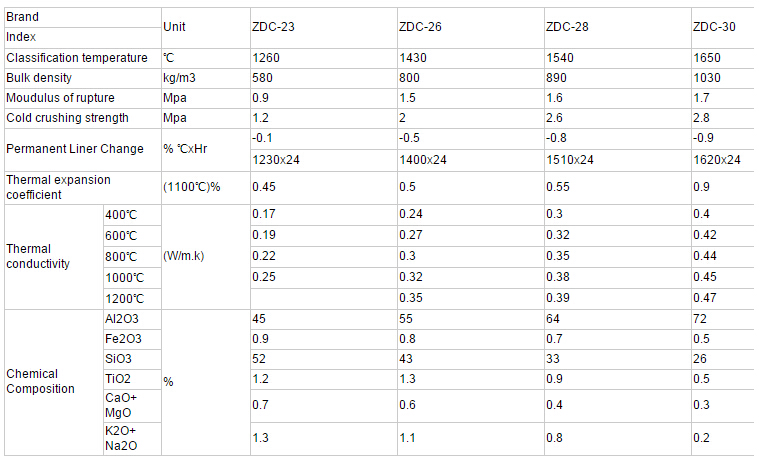

Technical Specification:

- Q: Do insulating fire bricks have a high fireproof rating?

- Yes, insulating fire bricks have a high fireproof rating. They are designed to withstand high temperatures and provide excellent insulation, making them ideal for applications where fire resistance is necessary.

- Q: Are insulating fire bricks resistant to molten salts?

- Insulating fire bricks are known for their general resistance to molten salts. These bricks are specifically designed to endure high temperatures and provide excellent thermal insulation. They are typically crafted from special refractory materials with a high melting point and chemical inertness. In contrast, molten salts have a corrosive nature that can cause harm to various materials. Nevertheless, insulating fire bricks can endure the corrosive effects of molten salts due to their distinctive composition. Their dense structure and superior refractory properties enable them to resist the corrosive impact of molten salts over extended periods. Moreover, insulating fire bricks find widespread use in industries like metal smelting, glass manufacturing, and chemical processing, where encounters with molten salts are common. Their resistance to molten salts makes them highly suitable for applications involving these corrosive substances. However, it is important to note that the specific resistance of insulating fire bricks to molten salts can vary depending on the brick's composition and the type of molten salt used. Therefore, it is recommended to consult the manufacturer or a refractory materials specialist to ensure the appropriateness of insulating fire bricks for a particular application involving molten salts.

- Q: Do insulating fire bricks have a high electrical resistivity?

- Yes, insulating fire bricks generally have a high electrical resistivity. This is because these bricks are specifically designed to have low thermal conductivity and high thermal resistance, which also translates into high electrical resistivity. The insulating materials used in these bricks, such as alumina, silica, and other refractory materials, have inherently high electrical resistivity. Additionally, the manufacturing processes often involve the addition of insulating additives, further enhancing the electrical resistivity of the fire bricks. As a result, insulating fire bricks are effective in reducing heat transfer and maintaining high temperatures in various industrial applications, such as kilns, furnaces, and thermal insulation systems.

- Q: Are insulating fire bricks resistant to ammonia gas?

- Yes, insulating fire bricks are generally resistant to ammonia gas. Their high temperature resistance and low thermal conductivity make them suitable for applications involving ammonia gas. However, it is always recommended to refer to the specific manufacturer's specifications and consult with experts to ensure the compatibility of insulating fire bricks with ammonia gas in a particular setting.

- Q: Can insulating fire bricks be used in refractory lining applications?

- Yes, insulating fire bricks can be used in refractory lining applications. These bricks are designed to have low thermal conductivity, making them ideal for insulation purposes in high-temperature environments.

- Q: Can insulating fire bricks be used in cement kilns?

- Yes, insulating fire bricks can be used in cement kilns. Insulating fire bricks are designed to have low thermal conductivity, which makes them ideal for insulating high-temperature environments such as cement kilns. These bricks can help to reduce heat loss and improve energy efficiency in the kiln. Additionally, their lightweight nature makes them easier to handle and install in the kiln. However, it is important to ensure that the insulating fire bricks selected are compatible with the specific operating conditions and requirements of the cement kiln to ensure optimal performance and longevity.

- Q: Do insulating fire bricks emit any harmful gases when heated?

- No, insulating fire bricks do not emit any harmful gases when heated. They are specifically designed to have excellent thermal insulation properties without releasing any harmful emissions.

- Q: Are insulating fire bricks resistant to oil or chemical spills?

- Insulating fire bricks lack resistance to oil or chemical spills in general. Their main purpose is to endure high temperatures and offer insulation in various settings, such as furnaces, kilns, and fireplaces. Despite their efficient handling of heat and thermal shock, these bricks are typically composed of materials like clay, alumina, or silica, which do not possess inherent resistance to oil or chemicals. In the event of exposure to oil or chemical spills, these bricks may absorb the substances, potentially resulting in degradation or diminished performance over time. Hence, if oil or chemical resistance is a crucial requirement, it is advisable to explore alternative materials explicitly designed for such applications.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Insulating fire bricks exhibit exceptional resistance to weathering and aging. These bricks are specifically engineered to endure extreme temperatures and harsh environmental conditions. They are composed of top-notch refractory materials, including alumina, silica, and other additives, which confer exceptional thermal insulation properties and strong resistance to corrosion and erosion. The manufacturing process of insulating fire bricks entails meticulous selection of raw materials and precise control of firing temperatures, resulting in a dense and homogeneous structure. This structure effectively prevents moisture and other weathering agents from infiltrating, thus ensuring extended durability and resistance to aging. Moreover, insulating fire bricks are also highly resistant to thermal shock, enabling them to withstand rapid temperature fluctuations without fracturing or disintegrating. This characteristic bolsters their ability to withstand adverse weather conditions. All in all, insulating fire bricks have demonstrated remarkable dependability in diverse applications that involve exposure to weathering elements. They find widespread usage in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

- Q: What is the maximum temperature that insulating fire bricks can withstand?

- Insulating fire bricks can withstand temperatures up to 3000°F (1650°C).

Send your message to us

Insulating Fire Brick - Refractory JM Mullite Insulation Brick ZDC-26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords