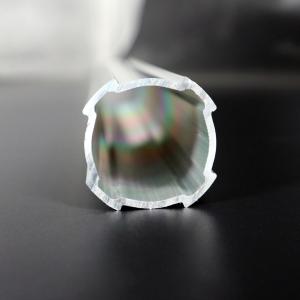

Rebar #4 Diameter Hot Rolled Steel Rebars EN Standard High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Hot Rolled Steel Rebars EN Standard in High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Rebars EN Standard in High Quality are ideal for structural applications and are widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material..

Product Advantages:

OKorder's Hot Rolled Steel Rebars EN Standard in High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | ||

Type | Hot rolled steel rebar | ||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q:What is the purpose of using stirrups with steel rebars?

- The purpose of using stirrups with steel rebars is to provide additional strength and stability to reinforced concrete structures. Stirrups, which are typically U-shaped or circular, are placed around the vertical rebars to prevent them from buckling or collapsing under tension. They help distribute the load evenly across the entire structure, enhancing its durability, resistance to bending, and overall structural integrity.

- Q:Can steel rebars be used in soundproof structures?

- Steel rebars, although they can be utilized in soundproof structures, do not bear the sole responsibility for soundproofing. Their main purpose lies in reinforcing concrete structures like walls or floors. While they can somewhat assist in diminishing sound transmission, accomplishing effective soundproofing necessitates the use of supplementary materials and techniques. To establish a soundproof structure, various factors must be taken into account. One crucial aspect is the mass of the structure. Due to their weight and density, steel rebars augment the mass of the structure, thus aiding in reducing sound transmission. Nevertheless, the efficacy of soundproofing also relies on the overall design, construction techniques, and integration of other sound-absorbing materials. To heighten the soundproofing capabilities of a structure, additional materials can be incorporated, such as acoustic insulation, soundproofing panels, or resilient channels. Acoustic insulation materials like mineral wool or acoustic foam can be installed within the walls or floors to absorb sound waves and prevent their passage through the structure. Soundproofing panels can also be affixed to surfaces to either reflect or absorb sound waves, further diminishing noise transmission. Furthermore, proper construction techniques should be employed to ensure the absence of gaps or air leaks that may permit sound to travel through. The utilization of resilient channels, which isolate the structure from surrounding surfaces, can also aid in reducing sound transmission. In conclusion, while steel rebars can contribute to the soundproofing of a structure through the augmentation of its mass, they alone are inadequate for achieving a fully soundproof environment. Effective soundproofing necessitates a combination of design, construction techniques, and the integration of supplementary sound-absorbing materials to attain the desired level of sound reduction.

- Q:Are steel rebars suitable for use in structures with high resistance to impact?

- Steel rebars are generally suitable for use in structures with high resistance to impact. Rebars, also known as reinforcement bars, are made from steel and are commonly used in concrete structures to enhance their strength and durability. Steel is known for its high tensile strength and ability to absorb and distribute impact forces, making it an ideal material for reinforcement. In structures that are prone to impact, such as bridges, highways, or buildings located in earthquake-prone areas, steel rebars play a critical role in providing additional strength and resistance. The use of rebars ensures that the structure can withstand sudden impact loads and prevent catastrophic failures. Moreover, steel rebars are available in various grades and sizes, allowing engineers to select the appropriate type of rebar based on the specific requirements of the structure. Higher grade rebars, such as Grade 60 or Grade 75, offer increased strength and ductility, making them even more suitable for structures with high resistance to impact. It is important to note that while steel rebars enhance the overall strength and impact resistance of a structure, other factors such as design, construction techniques, and maintenance also play vital roles in ensuring the structure's ability to withstand impact forces. Therefore, a comprehensive approach that considers all these factors is essential in designing and constructing structures with high resistance to impact.

- Q:Can steel rebars be used in bridge expansion joint construction?

- Yes, steel rebars can be used in bridge expansion joint construction. Steel rebars provide reinforcement and stability to the structure, making them suitable for use in bridge expansion joints where movement and stress can occur.

- Q:What is the recommended spacing between inclined steel rebars in slabs?

- The recommended spacing between inclined steel rebars in slabs varies depending on the specific design requirements and load conditions. However, in general, a spacing of around 2 to 3 times the diameter of the rebar is often recommended to ensure proper reinforcement and structural integrity. It is important to consult with structural engineers or refer to local building codes for precise guidelines applicable to the specific construction project.

- Q:What is the effect of steel rebars on the seismic performance of a structure?

- Steel rebars, also known as reinforcing bars, play a crucial role in enhancing the seismic performance of structures. When subjected to seismic forces, structures experience intense shaking and vibrations. The presence of steel rebars significantly improves the overall strength and ductility of a structure, helping it to withstand and absorb the energy generated during an earthquake. One of the primary effects of steel rebars is their ability to increase the tensile strength of concrete. Concrete is strong in compression but weak in tension. By embedding steel rebars within the concrete, the composite material becomes capable of resisting tensile forces that may arise during an earthquake. This prevents the concrete from cracking or breaking apart, ensuring the structure remains intact and functional. Moreover, steel rebars act as a reinforcement mechanism by distributing the seismic load across the entire structure. During an earthquake, the shaking motion is dispersed throughout the building, reducing the concentration of stress on specific areas. This redistribution of forces helps to maintain the overall stability of the structure, preventing localized failure and collapse. Additionally, the presence of steel rebars enhances the ductility of the structure. Ductility refers to the ability of a material to deform under stress without fracturing. When seismic forces act on a building, the steel rebars provide flexibility and allow for controlled deformation. This plastic behavior helps to dissipate the energy generated during an earthquake, effectively reducing the impact on the structure and minimizing potential damage. Furthermore, steel rebars also contribute to the overall stiffness of the structure. By reinforcing concrete elements such as columns, beams, and walls, the rigidity of the entire system is increased. This stiffness helps to limit the displacement and deformation of the structure, mitigating the risk of structural failure and ensuring the safety of occupants during a seismic event. In summary, the presence of steel rebars in a structure significantly improves its seismic performance. They enhance the tensile strength of concrete, distribute seismic load, improve ductility, and increase overall stiffness. These effects collectively enhance the structure's ability to resist and withstand the forces generated during an earthquake, ensuring its integrity and the safety of its occupants.

- Q:Can steel rebars be used in cold weather concreting?

- Yes, steel rebars can be used in cold weather concreting. However, it is important to take necessary precautions and follow guidelines to ensure the rebars remain free from corrosion in low temperatures. Additionally, using proper construction techniques and allowing sufficient time for curing can help prevent any negative effects on the concrete due to cold weather conditions.

- Q:Can steel rebars be used in bridge construction projects?

- Yes, steel rebars can be used in bridge construction projects. They provide strength and reinforcement to the concrete used in bridge construction, making it more durable and capable of withstanding heavy loads and forces.

- Q:How do steel rebars comply with building codes and regulations?

- Steel rebars comply with building codes and regulations by meeting specific requirements outlined in these codes. These requirements include the dimensions, strength, and quality of the rebars, as well as their placement and spacing within the concrete structures. Compliance is ensured through rigorous testing and certification processes, ensuring that the rebars meet the necessary standards for safety and structural integrity in construction projects.

- Q:What are the common quality issues found in steel rebars?

- Some common quality issues found in steel rebars include insufficient strength or hardness, improper dimensions or shape, surface defects such as cracks or rust, and inadequate corrosion resistance. Other issues may include improper labeling or marking, poor welding or bonding properties, and inconsistent mechanical properties throughout the rebar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar #4 Diameter Hot Rolled Steel Rebars EN Standard High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords