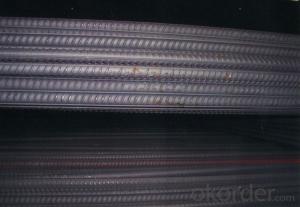

HRB500 hot rolled ribbed steel bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Definition

That is the new standard name for HRB500 steel, grade four steel as the old name, as a kind of hot rolled ribbed bar. In the construction industry, four screw steel is the old saying.

Hot rolled ribbed steel grades by HRB and number of yield points minimumcomposition. H, R, B respectively (Hotrolled), hot rolled ribbed steel bar(Ribbbed), (Bars) the three word's first letter English.

Classification

Hot rolled ribbed steel bar is divided into HRB335 (the old number is 20MnSi),HRB400 (the old No. 20MnSiV, 20MnSiNb, 20Mnti), HRB500 three brands.

Hot rolled bars of fine grains in the grades of hot rolled ribbed bar after Englishabbreviation "fine" English (Fine) the first letter. Such as: HRBF335, HRBF400,HRBF500.

A suitable grade higher requirements for seismic structures: add E in the existing brands after (for example: HRB400E, HRBF400E

The main purposes

HRB500 grade steel in strength, ductility, high temperature resistance, low temperature performance and seismic performance and fatigue performanceare better than HRB400 has greatly improved, mainly used in high-rise and super high-rise building, long span bridges, high standards of construction, is an international engineering standards recommended actively and has been widely used in developed countries products, it shows that the application ofpractice HRB500 steel works, can save a lot of steel, and has obvious economic benefit and social benefit.

The main origin

Screw thread steel producers in China are mainly distributed in North and northeast, North China area such as Shougang, Tang Gang, Xuan Steel,bearing steel, Shanxi Zhongyang steel plant, Baoding Purui the steel, the northeast area such as resistant, Tai, realize, these two areas account for about 50% of the total output in the screw thread steel.

The difference between the screw thread steel and round steel bar is provided with longitudinal ribs and transverse ribs surface, usually with two longitudinalribs and transverse ribs along the length direction of the uniform distribution.Screw thread steel belongs to the small steel steel, mainly used in reinforced concrete building components of the skeleton. In use requires a certainmechanical strength, bending deformation properties and process of welding performance. Screw thread steel billet production raw material for the carbon structure steel smelting processing sedation or low alloy structural steel,finished steel for hot rolling, normalizing or hot-rolled state of delivery.

Advantage

Nationwide, the annual if 20000000 t two screw thread steel is four level(HRB500) to replace, can save more than 5000000 t screw thread steeldosage. Equivalent to an annual consumption of iron ore 4000000 ~800 million T, save standard coal 1670000 ~335 million T, less consumption of fresh water 9600000 ~1740 million m3, to reduce dust emissions of sulfur dioxide emissions reduction of 750~1500t, 625~1250t, energy saving and emission reduction effectiveness is huge, consistent with the low carbon environmental protection concept of current international society pay more and more attention.

The promotion of the work

In order to make better performance, more economical and four screw steelproducts of low carbon environmental protection at home and rapidly applied,gradually to replace the two screw steel low level, should do the following aspects of work:

1 wide publicity to introduce four screw steel composition, properties and their own advantages, strengthen the construction design institute relevant indexes of four screw steel chemical composition, mechanical properties and welding performance of the understanding, promote the use of the design of the construction project, to lay a solid foundation for the four screw steel market promotion.

Each of the 2 key projects on strengthening highway, railway, bridge, and a series of infrastructure projects, do a good job of key projects of the bidding work, the realization of the four screw steel supply breakthrough from thelarge-scale key projects, the formation of a demonstration effect on other common construction project and the real estate industry, and graduallypenetrated into all fields of thread steel application, so as to fully replace thelow grade screw thread steel.

- Q: Are there any limitations on the diameter of steel rebars?

- Steel rebars have limitations on their diameter. Typically, national and international building codes and standards regulate and standardize the diameter of steel rebars. These codes and standards guarantee that the rebars utilized in construction projects meet safety requirements by being of suitable size and strength. The actual restrictions on the diameter of steel rebars may differ based on their intended purpose and the specific regulations implemented. Nevertheless, it is customary to encounter construction projects utilizing rebars with diameters ranging from 6mm to 50mm.

- Q: What are the common mistakes to avoid when installing steel rebars?

- When installing steel rebars, there are several common mistakes that should be avoided to ensure a successful and safe installation: 1. Improper placement: One of the most common mistakes is placing the rebars in the wrong location. It is essential to follow the engineering or construction drawings precisely to ensure accurate placement. Any deviation from the specified location can compromise the structural integrity of the reinforced concrete. 2. Insufficient cover: Another mistake is not providing enough concrete cover over the rebars. The cover serves as a protective layer, preventing the rebars from corrosion and providing fire resistance. Inadequate cover can lead to premature deterioration and structural failure over time. 3. Inadequate bar support: Proper support for the rebars is crucial to maintain their position during the concrete pouring process. Insufficient support can cause the rebars to sag or move, resulting in an uneven distribution of steel reinforcement, which can compromise the structural strength of the concrete. 4. Poor alignment and spacing: Rebars should be aligned and spaced correctly according to the design specifications. Improper alignment can lead to congestion, difficulty in pouring concrete, and compromised bond strength between the rebar and concrete. Similarly, incorrect spacing can result in insufficient reinforcement, reducing the overall strength of the structure. 5. Failure to clean and remove rust: Before installation, rebars should be thoroughly cleaned to remove any rust, dirt, or other contaminants. Failure to clean the rebars properly can lead to poor bond strength and increased risk of corrosion, which can weaken the structure over time. 6. Inadequate tying: Tying rebars together with the appropriate wire or connectors is essential to maintain proper alignment and ensure the structural integrity of the reinforced concrete. Neglecting to tie the rebars adequately can result in shifting or movement during the concrete pouring process, leading to compromised structural strength. 7. Lack of supervision and quality control: Finally, a common mistake is the absence of proper supervision and quality control during the installation process. It is crucial to have experienced personnel overseeing the installation to ensure compliance with the design specifications, proper installation techniques, and adherence to safety guidelines. By avoiding these common mistakes, the installation of steel rebars can be carried out effectively, resulting in a strong, durable, and safe reinforced concrete structure.

- Q: Can steel rebars be used in structures with high resistance to vibration?

- Yes, steel rebars can be used in structures with high resistance to vibration. Steel rebars are commonly used as reinforcement in concrete structures to increase their strength and durability. The use of steel rebars enhances the structural integrity of a building or infrastructure, making it more resistant to various forces, including vibrations. Steel rebars possess excellent tensile strength and stiffness, which allows them to absorb and distribute the applied loads evenly throughout the structure. This property helps to minimize localized stress concentrations that could lead to vibrations or structural failure. Additionally, steel rebars can effectively control the crack widths and prevent the propagation of cracks, further enhancing the structure's resistance to vibrations. Moreover, steel rebars can be designed to meet specific requirements based on the expected vibration levels. By utilizing rebars with appropriate diameters, spacing, and anchorage details, the structure can be engineered to withstand vibrations caused by various external factors, such as earthquakes, wind loads, or nearby machinery. It is crucial to ensure proper design and detailing of steel rebars in structures with high resistance to vibration. The reinforcement layout should be carefully planned to account for the anticipated forces and vibrations. Additionally, the rebars should be adequately anchored and connected to other structural members to maintain their effectiveness in resisting vibrations. Overall, steel rebars are a reliable and widely-used reinforcement material that can significantly enhance the resistance of structures to vibrations when designed and implemented correctly.

- Q: How do steel rebars improve the flexural strength of concrete?

- Steel rebars improve the flexural strength of concrete by providing tensile strength, which is typically lacking in concrete. The rebars act as reinforcement, absorbing the tension forces that occur when the concrete is subjected to bending or flexing. This combination of concrete and steel rebars creates a composite material that is stronger and more resistant to cracking or breaking under flexural loads.

- Q: What are the cost implications of using steel rebars in construction?

- The cost implications of using steel rebars in construction can vary depending on several factors. Steel rebars are generally more expensive than alternative materials such as concrete, but they offer several advantages that can offset the higher upfront cost. Using steel rebars can lead to quicker and easier construction processes, as they are readily available and can be easily installed. This can result in reduced labor costs and shorter construction timelines, which can be beneficial for overall project costs. Moreover, steel rebars offer excellent strength and durability, making them a reliable choice for reinforcing concrete structures. They can enhance the structural integrity of buildings, bridges, and other infrastructure, potentially reducing the need for costly repairs or maintenance in the long run. However, it is important to consider the potential costs associated with corrosion protection for steel rebars, as they are prone to rusting when exposed to moisture or harsh environments. Implementing appropriate measures, such as proper coating or using stainless steel rebars, can help mitigate these costs. Overall, while steel rebars may incur higher initial expenses, their numerous advantages in terms of strength, durability, and construction efficiency often make them a cost-effective choice in the long term.

- Q: Are steel rebars easy to handle and transport?

- Steel rebars are generally easy to handle and transport due to their relatively lightweight and compact nature. The smaller sizes of rebars, such as those commonly used in construction, can be easily lifted by workers without the need for heavy machinery. Additionally, their straight and elongated shape allows for convenient stacking and bundling, making them easier to store and transport. Furthermore, steel rebars can be easily cut and bent on-site using simple tools, which adds to their ease of handling during construction projects. However, it is important to note that larger and heavier rebars may require special equipment or machinery for handling and transportation to ensure safety and efficiency.

- Q: Can steel rebars be painted or coated?

- Yes, steel rebars can be painted or coated. Painting or coating steel rebars helps to protect them from corrosion and extend their lifespan. It is a common practice in construction and reinforcement projects to apply paint or protective coatings on steel rebars to enhance their durability and resistance to environmental factors.

- Q: What are the different types of coatings available for steel rebars?

- There are several types of coatings available for steel rebars, including epoxy, galvanized, and black oxide coatings. Each type of coating provides different levels of protection against corrosion and helps to extend the lifespan of the rebars in various environments.

- Q: What are the guidelines for storing steel rebars on a construction site?

- The guidelines for storing steel rebars on a construction site typically include keeping them off the ground to prevent rust and corrosion, stacking them neatly and securely to avoid accidents, and protecting them from exposure to moisture and other harmful elements. It is also important to separate different sizes and types of rebars to ensure easy identification and accessibility when needed.

- Q: What are the guidelines for the proper curing of concrete with steel rebars?

- The proper curing of concrete with steel rebars requires adherence to the following guidelines: 1. Moisture: To ensure proper hydration and strength development, it is necessary to maintain moisture during the curing process. However, excessive moisture should be avoided when curing concrete with steel rebars to prevent corrosion and damage. Therefore, it is important to strike a balance between providing sufficient moisture and preventing the accumulation of standing water around the rebars. 2. Covering: During the pouring process, it is crucial to adequately cover the steel rebars with concrete to protect against corrosion. The thickness of the cover should meet the design specifications to ensure adequate strength and durability. 3. Curing time: The curing time for concrete with steel rebars is typically longer than that of plain concrete. This is due to the need for the steel to bond with the concrete and achieve proper adhesion. The recommended curing period may vary depending on factors such as ambient temperature, humidity, and the specific type of steel used. It is important to refer to the project specifications or consult with a structural engineer to determine the appropriate curing time for the specific application. 4. Temperature control: Temperature control is essential during the curing process to ensure uniform hydration and prevent thermal stress. Rapid temperature changes can lead to cracking and compromise the integrity of the concrete. Therefore, it is important to protect the concrete from extreme temperature variations and provide insulation or shading as necessary. 5. Protection from external elements: Concrete with steel rebars must be safeguarded against external elements that can cause damage or corrosion. This includes protection from chloride ions, carbonation, and chemicals. Additional protection can be provided by applying suitable surface coatings or sealants. 6. Inspection and maintenance: Regular inspection and maintenance are vital for ensuring the long-term durability of concrete with steel rebars. It is important to monitor for signs of corrosion, cracking, or deterioration and take appropriate action promptly. This may involve repairing damaged areas, applying protective coatings, or implementing measures to prevent corrosion. By following these guidelines, the proper curing of concrete with steel rebars can be achieved, resulting in a construction material that is structurally sound and durable, capable of withstanding the test of time.

Send your message to us

HRB500 hot rolled ribbed steel bars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords